Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CE、ISO

Model Number: FeiChun 2000919

Payment & Shipping Terms

Minimum Order Quantity: 1000 M

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

Outstanding Abrasion Resistance: |

Exceptional Durability To Withstand Wear And Tear In Demanding Industrial Environments |

Noise Reduction Technology: |

Integrates Features To Minimize Operational Noise, Creating A Quieter Working Environment |

Chemical Stability: |

Maintains Stability In The Presence Of Different Chemicals, Ensuring Long-term Reliability |

Chemical Resilience: |

Maintains Performance Integrity In The Presence Of Challenging Industrial Chemicals |

Temperature Versatility: |

Operates Seamlessly Across A Broad Temperature Range, Suitable For Diverse Climates And Conditions |

Minimal Maintenance Needs: |

Reduced Maintenance Requirements, Contributing To Overall Cost-effectiveness |

Outstanding Abrasion Resistance: |

Exceptional Durability To Withstand Wear And Tear In Demanding Industrial Environments |

Noise Reduction Technology: |

Integrates Features To Minimize Operational Noise, Creating A Quieter Working Environment |

Chemical Stability: |

Maintains Stability In The Presence Of Different Chemicals, Ensuring Long-term Reliability |

Chemical Resilience: |

Maintains Performance Integrity In The Presence Of Challenging Industrial Chemicals |

Temperature Versatility: |

Operates Seamlessly Across A Broad Temperature Range, Suitable For Diverse Climates And Conditions |

Minimal Maintenance Needs: |

Reduced Maintenance Requirements, Contributing To Overall Cost-effectiveness |

In today’s industrial landscape, the need for reliable, high-performance control cables is greater than ever. Companies across sectors such as robotics, automation, and manufacturing require cables that can withstand continuous motion, harsh environments, and tight spaces.

Our Unshielded Chainflex Control Cable with copper conductor material is engineered to meet these challenges, offering a perfect solution for dynamic applications that demand durability, flexibility, and cost-efficiency.

This article will explore the features, benefits, and applications of unshielded continuous-flex cable systems, helping you understand why these cables are ideal for your industrial operations.

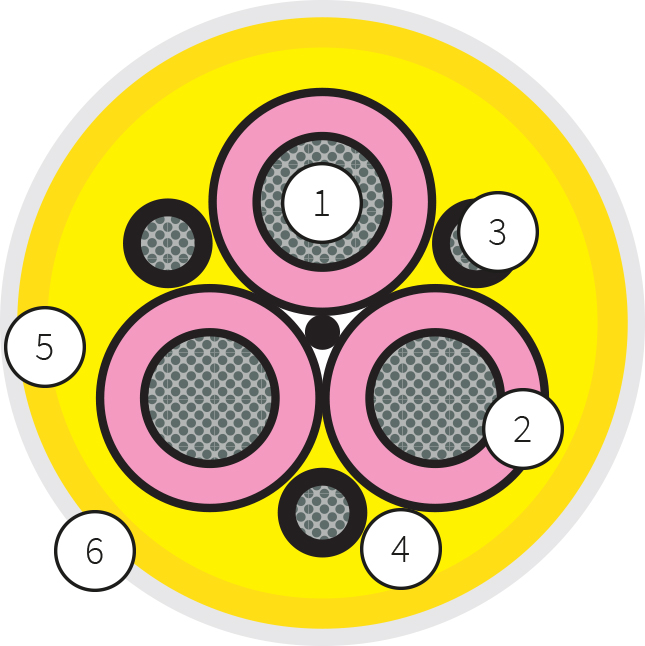

An unshielded Chainflex control cable is specifically designed for applications requiring continuous flexing, such as those found in energy chains and cable carriers. Unlike shielded cables, unshielded cables do not include a layer of metallic shielding.

This makes them lighter, more flexible, and cost-effective, especially in environments where electromagnetic interference (EMI) is not a major concern.

Our flexible control cables are made using copper conductors, which provide excellent conductivity, flexibility, and durability. This makes them ideal for use in dynamic control systems, robotics, and cable carrier systems.

There are several key reasons why businesses choose unshielded industrial cables over their shielded counterparts. Let’s dive into the key features and benefits of our unshielded control cables:

High Flexibility: Our cables are designed to handle tight bending radii, making them ideal for applications where cables need to flex continuously without damage. These cables maintain their flexibility even in high-speed and high-acceleration environments.

Cost-Effective: By eliminating the shielding, we reduce both the weight and the cost of the cable, making it an affordable solution for applications where EMI is not a significant factor.

Dynamic Applications: Perfect for use in energy chains, cable carriers, and cable tracks, these cables are engineered to withstand constant movement and bending, providing long-lasting durability.

Copper Conductor: With high-quality copper conductors, these cables offer excellent electrical performance, ensuring the efficient and reliable operation of your control systems.

Noise Insensitive: Our unshielded cable is suitable for use in noise-insensitive control systems, such as in applications where electromagnetic interference is not a major concern.

| Feature | Specification |

|---|---|

| Cable Type | Unshielded Chainflex Control Cable |

| Conductor Material | Copper |

| Operating Voltage | 300V to 600V |

| Temperature Range | -20°C to +80°C |

| Flexibility | Continuous flex |

| Bending Radius | Tight radii (up to 10x cable diameter) |

| Resistance | Oil, chemical, and UV resistance |

| Durability | Suitable for millions of bending cycles |

| Shielding | Unshielded |

These specifications highlight the durability, flexibility, and electrical performance that make our copper conductor control cables a great choice for various industrial applications.

Our unshielded control cables are versatile and suitable for a wide range of applications. Here are some of the key industries and uses:

Robots in industrial settings often require cables that can move with them as they perform repetitive tasks.

Our unshielded industrial cables for robotics are perfect for such applications, where flexibility and durability are essential. These cables are designed to handle tight bending radii and provide reliable performance over extended periods of continuous use.

In systems that use cable carriers or energy chains, such as automated machinery and production lines, cables must be able to flex continuously without degrading.

Our flexible control cables for cable carriers are ideal for this type of dynamic application, offering high flexibility and resistance to mechanical wear.

For control systems that involve high-speed and high-acceleration movements, such as in packaging machinery or material handling systems, our dynamic control cables ensure smooth and reliable performance. These continuous-flex cables can handle millions of bending cycles without failure.

In applications where budget constraints are important, such as in certain manufacturing environments, our cost-effective unshielded control cables provide a durable and reliable solution without the added expense of shielding.

These cables are a great option for noise-insensitive environments where EMI is not a concern.

For machinery and equipment that involve constant motion, such as conveyor systems or gantry robots, our Chainflex cables for energy chains are specifically designed to handle the wear and tear of continuous movement.

These cables maintain their integrity even in the most demanding environments.

| Feature | Unshielded Chainflex Cable | Shielded Control Cable |

|---|---|---|

| Shielding | None | Yes |

| Flexibility | High (continuous flex) | Moderate |

| Cost | Lower | Higher |

| Weight | Lightweight | Heavier |

| EMI Protection | Low (suitable for noise-insensitive environments) | High |

| Use in Dynamic Applications | Ideal | Moderate |

This comparison table showcases the benefits of choosing an unshielded continuous-flex cable for applications where shielding is not necessary, allowing for a more cost-effective and flexible solution.

One of the standout features of our unshielded Chainflex cables is their ability to flex continuously without losing performance. Whether you’re using them in energy chains or cable carriers, these cables are designed to withstand the rigors of constant motion, making them a great choice for dynamic environments.

By eliminating the shielding, we not only reduce the cost of the cable but also make it lighter. This is particularly beneficial in applications where reducing the overall weight of the system is important.

Plus, the cost-effective unshielded control cable makes it a smart choice for budget-conscious buyers.

Our unshielded Chainflex cables for dynamic applications are built to last. With resistance to oil, chemicals, and UV exposure, these cables can operate in harsh industrial environments without compromising their performance.

Their high durability ensures a long service life, reducing the need for frequent replacements and minimizing downtime.

Our cables feature high-quality copper conductors, which provide superior electrical performance compared to other conductor materials.

Copper is known for its excellent conductivity, flexibility, and resistance to corrosion, making it the ideal choice for control cables used in demanding environments.

In high-speed and high-acceleration environments, such as those found in automation and robotics, cables are often subjected to extreme mechanical stress.

Our Chainflex cables for high-speed and high-acceleration applications are engineered to handle these conditions, ensuring reliable performance even in the most demanding applications.

These cables are ideal for use in:

When it comes to choosing the right cable for dynamic industrial applications, our Unshielded Chainflex Control Cable with copper conductor material is the ideal solution. Designed for continuous flexing, high-speed movements, and harsh environments, these cables offer unparalleled flexibility, durability, and cost-effectiveness.

Whether you need a flexible control cable for cable carriers, a copper conductor control cable for tight bending radii, or a cost-effective unshielded cable for dynamic systems, we have the solution to meet your needs. Contact us today to discuss your specific requirements and find out how our unshielded control cables can improve the efficiency and reliability of your industrial operations.

RFQ: Common Questions and Answers

Q1: Can these unshielded control cables be used in high-speed applications?

Yes, our Chainflex cables for high-speed and high-acceleration applications are designed to handle extreme mechanical stress, ensuring reliable performance even in the most demanding environments.

Q2: Are these cables suitable for use in cable carriers or energy chains?

Absolutely. Our flexible control cables are engineered for dynamic applications and are perfect for use in cable carriers, energy chains, and cable tracks.

Q3: What is the advantage of using unshielded cables over shielded cables?

Unshielded cables are lighter, more flexible, and cost-effective. They are ideal for environments where electromagnetic interference is not a concern.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.