FeiChun Cables specializes in the manufacturing of high-quality mining power cable, mining trailing cable, and a comprehensive range of mining cables including reeling cables and mine power cables.

Our products meet the highest industry standards such as AS/NZS 1802:2003, AS/NZS 2802:2000, VDE, ICEA, and CAN/CSA.

Our cables ensure reliable performance for medium voltage fixed installations and other demanding mining applications.

When it comes to the demanding environment of the mining industry, selecting the right cable is crucial. Feichun Cable offers Australian standard mining cables known for their superior quality and performance, providing reliable solutions for global mining customers.

Our cables not only meet international and Australian standards but also excel in various challenging environments.

VDE_German_Standard_Feichun_Mining_Cable.pdf

United_States_&_Canada_Standards_Feichun_Mining_Cable.pdf

Australia_&_New_Zealand_Standards_Feichun_Mining_Cable.pdf

With over 25 years of industry experience, Feichun Specialty Cable Company is dedicated to developing and manufacturing high-quality mining cables. Our products cater to both underground and surface applications, ensuring stable power supply and safety in any environment.

Key Features

Our extensive range of mining cables includes:

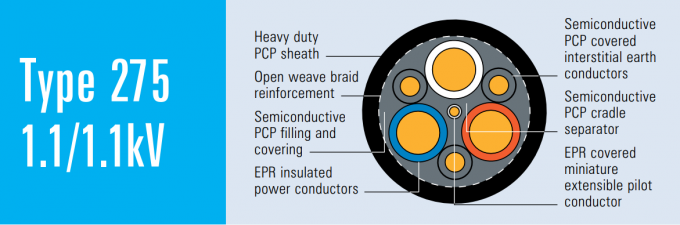

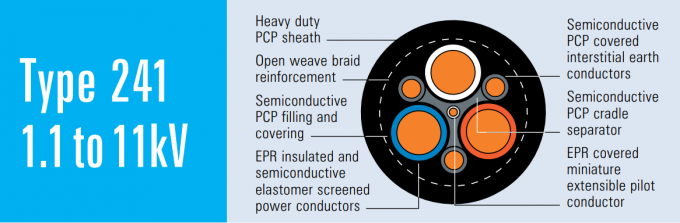

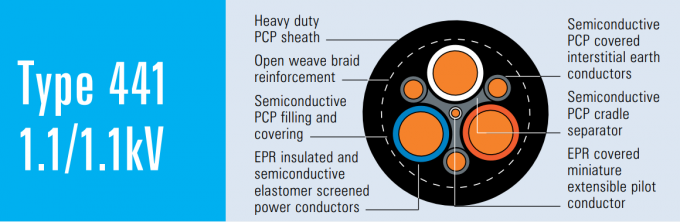

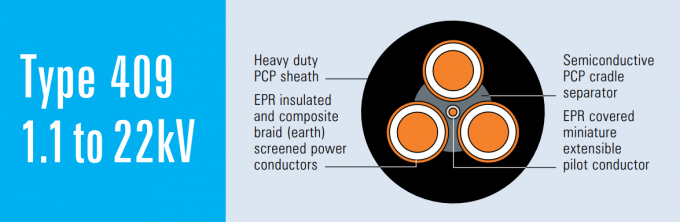

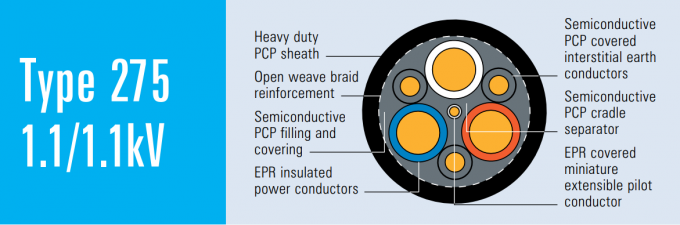

- Types 440, 441, 450, 409, 406, 245, 275, and 2S.

These cables are characterized by:

- Flame Resistance: Preventing the spread of fire in the event of a fire, ensuring the safety of miners and equipment.

- Abrasion Resistance: Withstanding wear and tear in harsh operating conditions, extending the cable’s lifespan.

- Flexibility: Remaining flexible even in low-temperature conditions, making installation and maintenance easier.

- Consistent Electrical Performance: Maintaining excellent power transmission performance in wet and harsh environments.

Applications

Our mining cables are designed for various mining scenarios, including but not limited to:

- Underground Mining: Such as coal mines and metal mines.

- Surface Equipment: Including cranes, excavators, draglines, and other large machinery.

- Transformer Stations and Power Supply Systems: Ensuring continuous and safe power supply.

Product Specifications

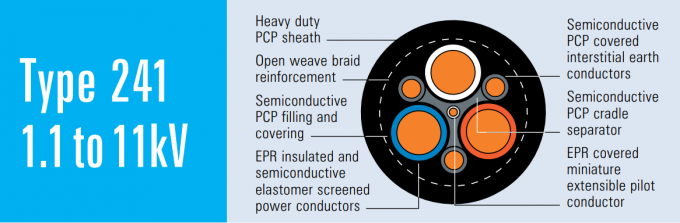

- Type 241.1 Cable: Manufactured according to AS/NZS 1802 standards, primarily used in coal mining and related activities.

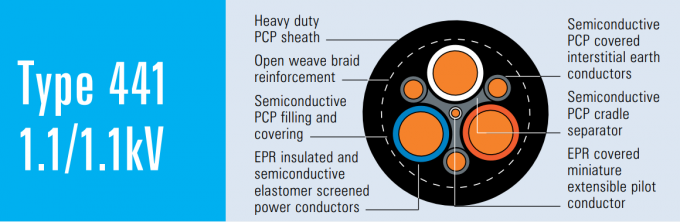

- Type 441 Cable: Features three earth cores and a semi-conductive pilot core, ideal for slow reeling and trailing applications, with voltage ratings up to 22kV.

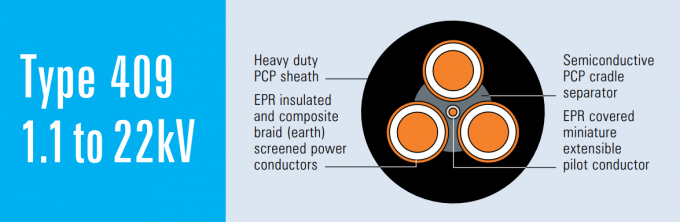

- Type 409 Cable: Specifically designed for powering high-voltage underground machinery such as cranes.

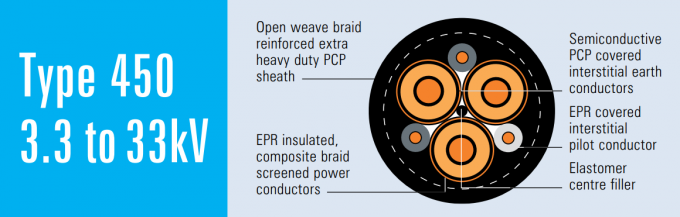

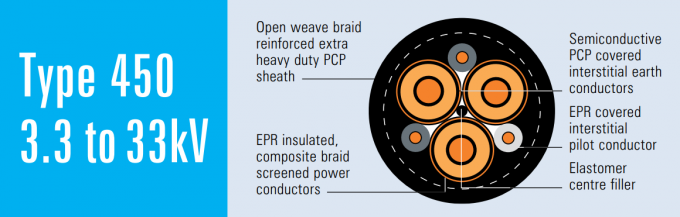

- Type 450 Cable: Suitable for slow reeling and trailing applications, with voltage ratings from 3.3kV to 33kV.

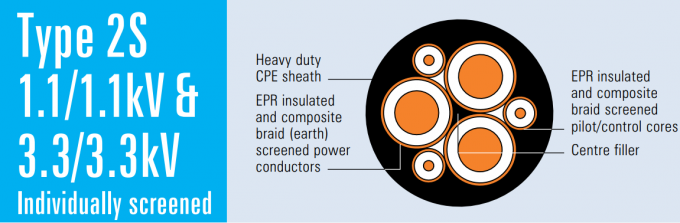

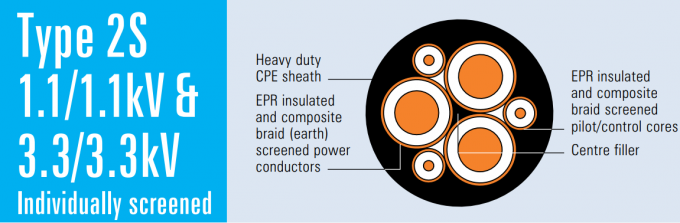

- Type 2S Cable: Copper-screened conductors, commonly used for high-voltage equipment and longwall lighting circuits.

Quality Assurance

All products from Feichun Specialty Cable Company undergo rigorous quality testing to ensure exceptional performance under the harshest conditions. Our cables are widely used globally, earning the trust and praise of our clients.

About Us

As a leading Australian Standards mining cable manufacturer and supplier, Feichun Specialty Cable Company is renowned for its innovation and excellence.

Whether for underground operations or surface mining, our cables are designed to meet your specific needs, providing top-tier safety and reliability.

Choose Feichun Specialty Cable Company and experience the difference in quality and service. Let us be your trusted partner in the mining cable industry, helping you tackle future challenges and opportunities.

Comprehensive Cable Solutions for Demanding Applications

Port & Maritime Applications

Container Terminal Solutions

Ship-to-Shore (STS) Cranes

High-speed reeling cables (up to 240m/min)

Enhanced corrosion resistance for marine environments

Specialized designs for heights up to 70 meters

Integrated fiber optic solutions for smart operations

Automated Guided Vehicles (AGV)

Flexible power and control cables

Enhanced durability for continuous movement

EMC-optimized designs

Resistance to oil and chemical exposure

Rail Mounted Gantry (RMG) Cranes

Medium voltage reeling cables

High mechanical strength

Enhanced weather resistance

Reliable performance in all weather conditions

Shipyard Applications

Shore Power Systems

High-voltage shore connection cables

Marine-grade construction

Advanced safety features

International certification compliance

Ship Loading Systems

Heavy-duty reeling cables

Superior bend radius performance

Enhanced abrasion resistance

Specialized composite cables with fiber optics

Mining Applications

Underground Mining

Longwall Mining Systems

ATEX-certified trailing cables

Enhanced flexibility for continuous movement

Superior mechanical protection

Flame-retardant construction

Continuous Miners

High-flex trailing cables

Advanced screening for EMI protection

Enhanced abrasion resistance

Specialized grounding systems

Shuttle Cars & Loaders

Medium voltage trailing cables

Enhanced tensile strength

Superior flexibility

Specialized jacket compounds

Surface Mining

Draglines & Excavators

Extra-flexible reeling cables

High mechanical strength

UV-resistant construction

Advanced wear protection

Mobile Crushing Units

Heavy-duty power cables

Enhanced vibration resistance

Superior weather protection

Reliable power transmission

Industrial Automation

Factory Automation

- Robot Systems

- High-flex control cables

- Enhanced torsional performance

- EMC-optimized designs

- Millions of flex cycles

- Automated Production Lines

- Servo motor cables

- Data transmission cables

- Power supply cables

- Bus system cables

Process Automation

- Continuous Production Systems

- Process control cables

- Instrumentation cables

- Temperature sensor cables

- Industrial ethernet solutions

Marine Applications

Vessel Systems

- Ship Board Systems

- Marine-grade power cables

- Control and instrumentation cables

- Fire-resistant designs

- Enhanced oil resistance

Navigation & Communication

- Bridge Systems

- Signal transmission cables

- Data communication cables

- Weather-resistant construction

- EMC protection

Technical Features & Advantages

Environmental Protection

- Operating temperature range: -50°C to +90°C

- UV resistance according to ISO 4892-2

- Enhanced oil resistance (EN 60811-404)

- Superior weather resistance

Mechanical Performance

- High tensile strength

- Enhanced abrasion resistance

- Superior flex life

- Advanced torsional capabilities

Safety Compliance

- IEC 60332-1-2 flame resistance

- Low smoke zero halogen options

- Enhanced fire resistance where required

- International safety certifications

Quality Assurance

- ISO 9001:2015 certified production

- Regular third-party testing

- Continuous quality monitoring

- Advanced testing facilities

Support Services

- Technical consultation

- Custom design services

- On-site support

- After-sales service

This comprehensive range of solutions demonstrates Feichun Cable's commitment to providing specialized cable solutions across diverse industrial applications, with particular expertise in port operations and mining environments.

Feichun Cable: Engineered for Extremes, Connecting the Unreachable with Specialized Precision!