Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CSA & UL

Model Number: KSR Robots Cable

Payment & Shipping Terms

Minimum Order Quantity: 1000 M

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Flex Life: |

10 Million Cycles |

Rugged Reliability: |

Built To Endure Harsh Industrial Environments, Guaranteeing Consistent Performance In Challenging Conditions. |

Torsion Resilience: |

Withstands Twisting And Torsion Movements, Ensuring Uninterrupted Flexibility In Robotic Applications |

Filler: |

Cotton,Non-woven Fabrics |

Application: |

Robotics |

Compact Design: |

Features A Space-efficient Design, Making It Suitable For Installations With Limited Space And Intricate Robotic Setups |

Lightweight Construction: |

Possesses A Lightweight Build, Reducing The Overall Weight Of Robotic Systems And Enhancing Energy Efficiency |

High Voltage Handling: |

Capable Of Handling High Voltage Levels, Catering To The Power Needs Of Sophisticated Robotic Components |

Flex Life: |

10 Million Cycles |

Rugged Reliability: |

Built To Endure Harsh Industrial Environments, Guaranteeing Consistent Performance In Challenging Conditions. |

Torsion Resilience: |

Withstands Twisting And Torsion Movements, Ensuring Uninterrupted Flexibility In Robotic Applications |

Filler: |

Cotton,Non-woven Fabrics |

Application: |

Robotics |

Compact Design: |

Features A Space-efficient Design, Making It Suitable For Installations With Limited Space And Intricate Robotic Setups |

Lightweight Construction: |

Possesses A Lightweight Build, Reducing The Overall Weight Of Robotic Systems And Enhancing Energy Efficiency |

High Voltage Handling: |

Capable Of Handling High Voltage Levels, Catering To The Power Needs Of Sophisticated Robotic Components |

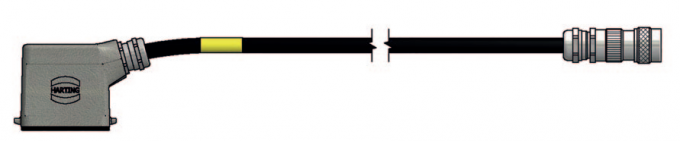

In the world of modern welding technology, KSR robot cables are revolutionizing how industries control welding processes with precision. These cables are specially designed for automated welding systems, such as KSR welding robots, where constant welding current is crucial for ensuring stability and precision.

The KSR robot cables have become essential for any operation that requires high performance in challenging environments.

Whether you're looking to improve efficiency in an industrial setting or need to ensure safety and reliability, these cables offer unique benefits tailored to welding automation needs.

A key feature of these cables is their ability to support constant welding current control. Welding quality can vary significantly if the current fluctuates, leading to inconsistencies in the welds, potential defects, and material waste.

Constant current welding ensures a stable arc during the process, which improves not only the quality of the weld but also the overall productivity of the operation.

For industries like automotive manufacturing, where every weld needs to be precise, precise welding current control is a necessity. By utilizing KSR welding robot cables, companies can enhance their operations and avoid costly mistakes.

These cables are designed to handle the tough demands of welding automation while ensuring stable arc welding wiring that maintains a continuous flow of current, leading to more reliable and accurate welds.

| Features | Description |

|---|---|

| High Flex Life | Designed for continuous movement in robotic arms, ensuring longevity and performance over time. |

| Oil & Chemical Resistant | Built to withstand exposure to oil, chemicals, and other harsh substances commonly found in industrial environments. |

| Torsion Resistant | Designed to endure twisting and bending during repetitive movements of robotic systems. |

| Temperature Range | Suitable for extreme temperatures, withstanding from -40°C to +90°C for versatile applications. |

| PWIS Uncritical | Free of paint-wetting interfering substances, ensuring the highest quality standards in applications like automotive welding. |

| RoHS Compliant | Complies with the RoHS directive of the European Union, ensuring the absence of harmful substances. |

KSR robot welding cables are engineered for environments that demand high flex life and oil and chemical resistance. These cables can handle continuous movements and the strain of repetitive motions within robotic systems, making them ideal for welding automation applications.

They are made to last, with a durable PUR (polyurethane) sheath that protects the internal wiring from harsh industrial elements. This torsion-resistant feature makes them stand out in industries where cables face twisting and pulling stresses daily.

Whether you're welding in extreme temperatures or in environments where exposure to oil and chemicals is common, KSR robot cables are up to the task. Their oil and chemical-resistant properties, combined with their flexibility, make them suitable for the most demanding applications.

Every industry has unique needs, and KSR robot cables cater to that by offering custom-made options. This means you can request cables with specific dimensions, lengths, or performance attributes to suit your welding robot systems.

For example, companies working in the automotive industry may require constant current welding cables that are both durable and flexible, while a chemical processing plant might need stable arc welding wiring with superior chemical resistance.

Here’s a quick look at some custom-made options:

| Cable Specifications | Dimension (SQMM) |

|---|---|

| 2 x (0.5) D + 2 x (0.5) D | Ideal for small robotic systems that require constant welding current control. |

| 3 x 1.0 D + 2 x 1.0 D + 1 x 1.0 | Suited for larger automated systems where precise welding current is crucial. |

| 6 x 0.75 + (3 x 0.75) D | For more complex setups where flexibility and durability are equally important. |

When selecting cables for robotic welding systems, KSR robot welding cables are the top choice because they offer unmatched flexibility and torsion resistance. The cables are designed specifically for constant welding current control, helping to ensure consistent, precise welding output over time. Below are just a few reasons why KSR robot cables are the best solution for your automation needs:

Enhanced Durability: With their PUR sheath and high-grade copper strands, these cables resist wear and tear even in the most challenging environments.

Reliable Welding Current Control: By maintaining a constant flow of current, these cables help produce high-quality, defect-free welds.

Customization: The ability to tailor the cables to your unique requirements, such as temperature resistance or chemical exposure, makes them versatile across industries.

PWIS Uncritical: Perfect for industries like automotive, where even minor contaminations can affect paint applications.

Compliance: Fully compliant with RoHS regulations, ensuring environmental and safety standards are met.

KSR robot welding cables are found in numerous industries due to their versatility, durability, and performance. Below are some of the key applications:

| Industry | Application |

|---|---|

| Automotive Manufacturing | Used in automated welding systems for assembling car frames, ensuring precise, repeatable welds with constant current welding. |

| Aerospace Engineering | Provides the high flexibility and durability needed in assembling components for aircraft, which require stable arc welding wiring. |

| Chemical Processing Plants | Resists harsh chemicals and oils commonly found in these environments, ensuring a longer lifespan for robotic systems. |

| Heavy Machinery Production | Ensures that robotic welders perform consistently under stress, increasing productivity and reducing downtime. |

An automotive manufacturer was facing issues with inconsistent welds due to fluctuating current in their robotic welding systems. By switching to KSR robot welding cables, they experienced a 25% improvement in weld quality and reduced waste.

The cables' ability to maintain constant welding current control helped the company optimize its production line.

A large chemical processing company needed cables that could withstand constant exposure to corrosive substances. After integrating KSR robot welding cables with oil and chemical resistance, they noted a significant improvement in cable longevity and reduced maintenance costs.

For industries looking to improve their robotic welding systems, KSR robot cables are the ideal solution. They offer unmatched durability, flexibility, and the ability to support constant welding current control.

With their customizable options and compatibility with various environments, they provide the reliability needed in today’s fast-paced industrial world.

Whether you’re in automotive, aerospace, or chemical processing, choosing KSR robot welding cables is a surefire way to enhance the performance and longevity of your systems.

What makes KSR robot cables ideal for constant current welding?

Their high flexibility, torsion resistance, and ability to maintain stable arc welding wiring make them perfect for systems that require consistent current flow.

Are KSR robot cables customizable?

Yes, they offer various dimensions and features such as chemical resistance, temperature resistance, and more to meet your specific needs.

Can KSR robot cables withstand harsh environments?

Absolutely. These cables are designed to resist chemicals, oils, and extreme temperatures, making them ideal for tough industrial conditions.

How do KSR cables improve welding performance?

By ensuring precise welding current control, they eliminate fluctuations in current that could affect weld quality.

For more detailed information or to place an order, feel free to contact our sales team and discover how KSR robot welding cables can optimize your operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.