Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CSA & UL

Model Number: Robots Control Cabl

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Turning Radius: |

Not Less Than 250MM |

Temperature Range: |

-40°C To 105°C |

Weight: |

Light |

Resistance To Oil And Chemicals: |

Yes |

Package: |

100 Meters/roll |

Adapted Robot Brands: |

ABB/FANUC/KUKA |

Conductor Material: |

Copper |

Flammability Rating: |

Combustible |

Voltage Rating: |

600V |

Filler: |

Cotton,Non-woven Fabrics |

Turning Radius: |

Not Less Than 250MM |

Temperature Range: |

-40°C To 105°C |

Weight: |

Light |

Resistance To Oil And Chemicals: |

Yes |

Package: |

100 Meters/roll |

Adapted Robot Brands: |

ABB/FANUC/KUKA |

Conductor Material: |

Copper |

Flammability Rating: |

Combustible |

Voltage Rating: |

600V |

Filler: |

Cotton,Non-woven Fabrics |

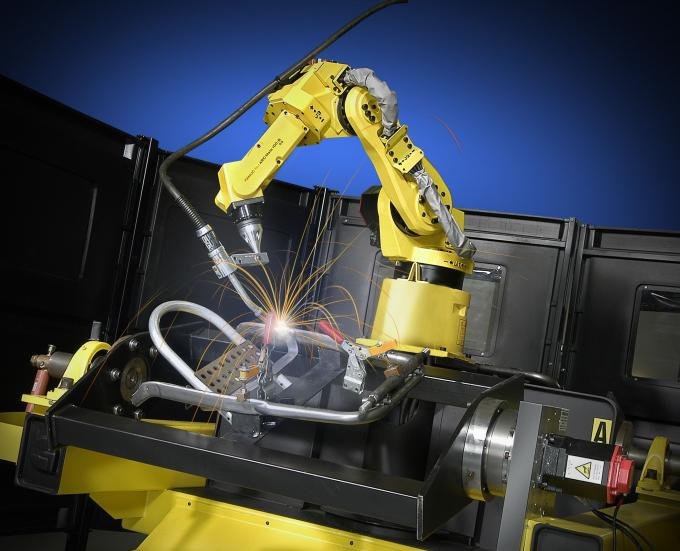

As industries increasingly move towards robotic automation, the demand for reliable, high-performance cabling solutions is at an all-time high. In industrial settings like welding applications, robots need to function with precision and flexibility.

This is where the Automaton Flex-Industrial Robots Control Cable for Welding Guns steps in. Designed specifically for the harsh environments of welding operations, this industrial robot control cable offers superior durability, flexibility, and resistance to heat, oil, and chemicals.

In this product introduction, we will explore the features, benefits, and key applications of our flexible automation control cable, engineered for robotic control in welding equipment.

An Automaton Flex cable is a high-performance robotic control cable designed to meet the challenges of industrial robot wiring in welding applications. The cable is built to handle repeated bending, torsion, and mechanical stress, ensuring long-lasting performance in robotic systems.

Whether you're working with welding guns, robotic arms, or other automation equipment, our robot control cable for welding is built to last.

Our robot control cable is designed for durability, safety, and efficiency in the most demanding industrial environments.

Here’s why it stands out:

High Flex Life: In flexible robotics, cables are subjected to continuous movement. Our cables are engineered for superior flex life, allowing them to withstand millions of flex cycles without damage. This ensures smooth operation in robotic automation systems.

Torsion Resistance: Robots often rotate and twist, which can wear down ordinary cables. Our robotic control wiring is torsion-resistant, making it perfect for harsh environments where frequent twisting occurs.

Oil and Chemical Resistance: In welding applications, robots are often exposed to oils, chemicals, and other hazardous substances. Our automation welding cable is designed to resist oil and chemicals, ensuring that it maintains peak performance in these challenging environments.

Heat Resistance: Welding processes generate high temperatures. Our robot control cable for welding equipment is heat-resistant, ensuring reliable operation even in high-heat conditions.

| Feature | Description |

|---|---|

| Material | High-quality copper conductor with PVC/TPU jacket |

| Operating Temperature | -40°C to 105°C |

| Flexibility | High flex life for continuous movement applications |

| Torsion Resistance | Supports multiple rotations and twists |

| Chemical Resistance | Resistant to oils, chemicals, and solvents |

| Voltage Rating | 300V to 600V |

| Insulation | Flame-retardant, oil-resistant PVC insulation |

| Certification | Complies with global safety standards |

Robotic systems in industrial automation are expected to function seamlessly under extreme mechanical stress. Our flexible robot control cables are designed with a high flex life, making them ideal for robotic arms, welding robots, and other robotic automation tasks where cables are in constant motion.

Safety is critical in industrial settings, especially in high-temperature welding applications. Our automation control cables are built to meet the highest safety standards, ensuring both performance and safety in robot control wiring.

Not all robotic systems are the same, and neither are their cabling needs. We offer custom-made welding equipment cables, tailored to your specific applications. Whether you need additional torsion resistance, higher temperature tolerance, or chemical resistance, we have the flexibility to meet your exact requirements.

Our automation welding cables are designed for various industries and applications, including:

Welding Robots: Designed for use in welding guns and robotic arms, our cables provide seamless control in welding applications, ensuring high flexibility and durability under heat and mechanical stress.

Automotive Manufacturing: In automotive production, robotic control cables are used in high-speed assembly lines where continuous motion and high heat are present.

Oil and Gas Industry: The oil-resistant automation welding cables are ideal for use in oil rigs and refineries, where equipment is exposed to hazardous chemicals and high temperatures.

Aerospace: Aerospace manufacturing requires precision and reliability. Our high-flex robot control cables ensure smooth operations for robotic automation used in the assembly of aircraft and spacecraft.

| Type of Cable | Ideal Application | Resistance | Flexibility |

|---|---|---|---|

| Flexible Robot Control Cable | Robotic arms, welding robots | Oil, chemical, torsion-resistant | Very High |

| Automation Welding Cable | Industrial robots for welding applications | High heat, oil, chemicals | High |

| Custom-Made Welding Equipment Cable | Specific welding systems with unique requirements | Tailored for specific environments | Medium to High |

| Standard Robot Control Wiring | Basic automation systems | Moderate resistance | Medium |

This table compares the different types of robot control cables and highlights the strengths of each option, making it easier for you to choose the right cable for your robotic systems.

Our robotic control cables are engineered with superior flexibility, durability, and resistance to the harsh environments typical of welding equipment.

| Specification | Details |

|---|---|

| Conductor Material | Stranded bare copper |

| Jacket Material | Special PVC or polyurethane (TPU) |

| Temperature Rating | Up to 105°C |

| Voltage Rating | 300V-600V |

| Flex Cycles | Up to 10 million flex cycles |

| Torsion Resistance | 5 million torsion cycles |

| Oil and Chemical Resistance | High |

| UV Resistance | Yes |

| Water Resistance | IP68 rated for water ingress protection |

These specifications showcase the robust performance and versatility of our robot control cables, which can handle the rigors of welding applications while maintaining flexibility and safety.

Case Study 1: Automotive Manufacturing

In a large automotive manufacturing plant, robotic arms equipped with flexible robot control cables are used for spot welding car parts. The cables need to withstand constant motion, high temperatures, and exposure to oils.

Our automation welding cable performed flawlessly, reducing downtime and extending the life of the robotic systems.

Case Study 2: Aerospace Industry

A leading aerospace manufacturer needed custom-made welding equipment cables for their robotic systems used in assembling aircraft components. The cables had to resist harsh chemicals and withstand high temperatures.

Our solution provided both durability and flexibility, ensuring the robotic systems could perform continuously without cable failures.

When selecting the right robot control wiring for your welding applications, consider the following factors:

Flexibility:

Ensure the cable can handle the required number of flex and torsion cycles. Our high flex life automation cables are ideal for robotic systems with continuous movement.

Heat and Chemical Resistance:

For welding equipment, the cable must resist both heat and exposure to oils and chemicals. Our oil and chemical-resistant robotic control cables are built to last in harsh environments.

Custom Requirements:

If your application has specific needs, such as unique chemical exposure or mechanical stresses, consider our custom-made welding equipment cables, designed for your unique application.

In today’s world of flexible robotics and robotic automation, the need for high-performance cables is undeniable. Whether you're working with welding robots, industrial automation systems, or material handling equipment, our Automaton Flex-Industrial Robots Control Cable for Welding Guns is the ideal choice.

With high torsion resistance, excellent chemical resistance, and long-lasting flex life, these cables ensure that your robotic systems run smoothly and efficiently in even the toughest conditions.

Whether you're looking for a custom-made welding equipment cable, or simply need a reliable, high-performance robotic control cable for your industrial robots, we’ve got you covered.

Contact us today to learn more about how our solutions can benefit your operation.

RFQ: Common Questions and Answers

Q1: Where can I buy flexible robot control cables for welding applications?

You can purchase our high-performance flexible robot control cables directly through our website or by contacting our sales team.

Q2: What are the benefits of using automation welding cables?

Our automation welding cables offer enhanced durability, heat resistance, and the ability to withstand harsh environments, making them ideal for industrial robots in welding applications.

Q3: How do your cables compare to other robot control cables on the market?

Our robot control cables offer superior torsion resistance, chemical resistance, and high flex life, making them the best option for welding applications and robotic automation.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.