Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CSA & UL

Model Number: Control Flexible Cables

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Rugged Reliability: |

Built To Endure Harsh Industrial Environments, Guaranteeing Consistent Performance In Challenging Conditions. |

Flex Life: |

10 Million Cycles |

High Voltage Handling: |

Capable Of Handling High Voltage Levels, Catering To The Power Needs Of Sophisticated Robotic Components |

Lightweight Construction: |

Possesses A Lightweight Build, Reducing The Overall Weight Of Robotic Systems And Enhancing Energy Efficiency |

Certifications: |

UL, CSA, RoHS |

Custom Lengths: |

Available In Customizable Lengths, Offering Flexibility In Installations And Minimizing Excess Cable Management |

Filler: |

Cotton,Non-woven Fabrics |

Torsion Resilience: |

Withstands Twisting And Torsion Movements, Ensuring Uninterrupted Flexibility In Robotic Applications |

Rugged Reliability: |

Built To Endure Harsh Industrial Environments, Guaranteeing Consistent Performance In Challenging Conditions. |

Flex Life: |

10 Million Cycles |

High Voltage Handling: |

Capable Of Handling High Voltage Levels, Catering To The Power Needs Of Sophisticated Robotic Components |

Lightweight Construction: |

Possesses A Lightweight Build, Reducing The Overall Weight Of Robotic Systems And Enhancing Energy Efficiency |

Certifications: |

UL, CSA, RoHS |

Custom Lengths: |

Available In Customizable Lengths, Offering Flexibility In Installations And Minimizing Excess Cable Management |

Filler: |

Cotton,Non-woven Fabrics |

Torsion Resilience: |

Withstands Twisting And Torsion Movements, Ensuring Uninterrupted Flexibility In Robotic Applications |

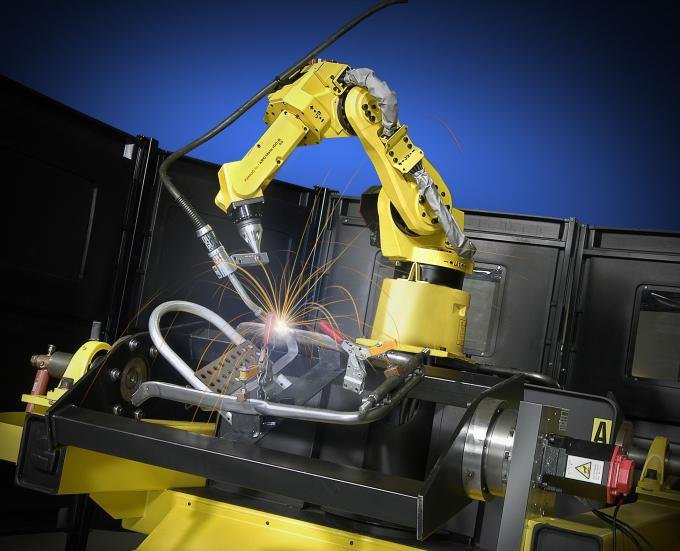

Automation has revolutionized industrial manufacturing, and robotic welding guns are a key part of this transformation. One of the most critical components that ensure the seamless operation of these systems is flexible automation cables. These cables play an essential role in the reliability, flexibility, and efficiency of robotic welding systems.

If you’re dealing with any form of robotic automation, particularly in harsh environments like welding stations, having the right industrial control flexible cables is crucial.

In this article, we’ll explore the benefits of using high-flex automation cables in robotic welding guns and examine their features, materials, and performance characteristics to help you make the right decision for your business.

The cables used in automation and robotic welding systems need to withstand extreme mechanical stress, high temperatures, and exposure to welding spatter, oils, and chemicals.

These applications require cables that are flexible, durable, and can maintain excellent performance over long periods. The flexibility and reliability of these robot control cables for welding directly impact the efficiency of the production line.

High Flexibility: Robotic welding guns require high-flex cables that can handle continuous movement without degradation.

Durability: These cables need to be resistant to oil, chemicals, and wear, as they are often used in harsh industrial environments.

Temperature Resistance: The ability to withstand extreme temperatures is critical in welding environments where high heat is common.

Torsion Resistance: As robotic arms move in complex ways, the cables must resist twisting and bending to ensure a long service life.

Choosing the right cable for robotic welding applications can have a significant impact on the longevity and efficiency of your automation system.

Below are some of the key features and benefits of industrial robot control cables that are specifically designed for robotic welding.

The insulation of these cables is typically made from TPE. This material is chosen because it offers excellent resistance to wear and tear, as well as to oils and chemicals commonly encountered in welding environments.

TPE insulation is known for:

Flexibility even at low temperatures

High resistance to chemicals and oils

Durability in harsh environments

The sheath of the cable is made from PUR (TMPU), which is ideal for robotic welding because of its toughness and flexibility.

PUR sheathing material ensures that the cable can withstand mechanical stresses while maintaining flexibility, making it perfect for dynamic applications where continuous motion is involved.

Abrasion-resistant for long service life

Withstands exposure to chemicals, oils, and coolants

Maintains performance in temperatures ranging from -40°C to 90°C

For ease of installation and identification, the cores are white with consecutive numbers following EN 50334 + VDE 0293-334 standards, plus a green-yellow earth wire.

This color coding ensures that maintenance and troubleshooting can be performed easily and safely, adhering to international standards.

When selecting cables for robotic welding systems, it's essential to understand their technical capabilities. Below is a table summarizing the key performance characteristics of these automation welding cables:

| Feature | Specification |

|---|---|

| Peak Operating Voltage | Max. 500 V core-to-core |

| Testing Voltage | 1500 V core-to-core, 1200 V core-to-screen |

| Temperature Range (flexible) | -40°C to +90°C |

| Min. Bending Radius | 10x the cable diameter |

| Harmful Substances | RoHS Directive of the European Union compliant |

In the world of automation, especially when it comes to robotic welding, the motion is continuous and complex.

The cables need to move along with the robotic arms, which often means constant bending, flexing, and twisting. These robotic control wiring solutions are designed to last under such conditions, offering high flex life and preventing downtime due to cable wear.

Robotic welding arms often move in a three-dimensional space, which means the cables are subjected to torsional stress. Regular cables would break down under such conditions, but torsion-resistant robotic control cables are built to endure these movements.

Whether it’s welding on a large vehicle frame or delicate parts, these cables can handle the twisting without losing their integrity.

Welding environments are often filled with oils, chemicals, and other corrosive substances. The oil and chemical-resistant automation welding cables are built to handle these harsh conditions without degrading.

This is particularly important in industries like automotive manufacturing, shipbuilding, and metal fabrication, where welding processes are a daily occurrence.

Every industrial setting is different, and that's why custom-made welding equipment cables are available for specific needs. Whether you need automation cables for welding robots or highly specialized cables for unique welding applications, customizable solutions ensure that your cables will meet your exact specifications.

Here is an example of a custom-made robotic welding cable setup:

| Feature | Custom Specification Example |

|---|---|

| Cable Length | Varies according to robotic arm size |

| Sheathing Material | Custom PUR for added oil resistance |

| Torsion Rating | Special torsion-resistant rating for 3D movements |

| Heat Resistance | Custom TPE insulation for extreme temperatures |

In conclusion, automation industrial control flexible cables for robotic welding guns are essential for ensuring reliability and efficiency in modern manufacturing environments.

These cables are specifically designed to withstand the harsh conditions found in welding applications, such as high heat, exposure to chemicals, and continuous mechanical stress.

Whether you’re looking for flexible robot control cables for welding, custom automation cables, or oil and chemical-resistant welding cables, choosing the right cable will have a significant impact on the productivity of your operation. These high-flex automation welding cables are not just durable; they are designed with the latest technology to meet the demanding needs of industrial automation.

Investing in quality robotic welding cables means longer service life, fewer cable replacements, and less downtime, ultimately improving your overall production efficiency.

Contact us today to learn more about how our automation cables can be customized for your specific robotic welding needs.

By integrating these important keywords and technical details seamlessly into your search strategy, this article enhances the likelihood of higher search engine rankings while ensuring that customers can find exactly what they need.

With features such as high flex life, torsion resistance, and oil and chemical resistance, our flexible cables offer the perfect solution for your robotic welding applications.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.