Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Twisting And Torsion Connection Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Long Lifespan: |

Extended Operational Life |

Product Type: |

Flexible Rubber Cable |

Flexibility: |

Extra Flexible |

Insulation Material: |

Rubber |

Weather Resistance: |

Resilient In Diverse Weather |

Standard: |

IEC 60245, VDE 0282-4 |

Corrosion Resistance: |

Resistant To Corrosion |

Temperature Rating: |

-25°C To +60°C |

Easy Installation: |

Flexible Installation |

Conductor Material: |

Copper |

Long Lifespan: |

Extended Operational Life |

Product Type: |

Flexible Rubber Cable |

Flexibility: |

Extra Flexible |

Insulation Material: |

Rubber |

Weather Resistance: |

Resilient In Diverse Weather |

Standard: |

IEC 60245, VDE 0282-4 |

Corrosion Resistance: |

Resistant To Corrosion |

Temperature Rating: |

-25°C To +60°C |

Easy Installation: |

Flexible Installation |

Conductor Material: |

Copper |

In the fast-evolving world of rail transportation, ensuring reliable and durable connections between bogies (the undercarriages on which the rail vehicle's body rests) and vehicle bodies is crucial.

With rail systems being more intricate and demanding than ever, the Twisting and Torsion Connection Cable (Twist-Proof Cable) offers a cutting-edge solution. Designed specifically for rail vehicles, this twist-proof cable excels in applications where mechanical stress, frequent twisting, and exposure to harsh environments are unavoidable.

If you're looking for a cable that is weather-resistant, UV & ozone resistant, and oil-resistant with flame-retardant properties, this twist-proof cable offers exactly what your project needs.

Let’s dive deeper into the features and benefits of this specialized connection cable, why it’s essential for modern rail systems, and how it can enhance the efficiency and longevity of your rail vehicles.

When rail vehicles are in operation, their components are constantly subjected to dynamic movements, whether due to vibrations, turning, or the mechanical forces associated with acceleration and deceleration. The connection points between the bogie and vehicle body are especially vulnerable to twisting, flexing, and other forms of mechanical stress.

Standard cables often fail to withstand these demands, leading to costly breakdowns, delays, and maintenance. That’s where the Twist-Proof Cable comes in.

Twist-Proof Cables are specially designed to:

Withstand constant twisting and torsion stresses.

Maintain electrical performance under challenging conditions.

Offer long-term durability even in extreme environments.

The Twist-Proof Cable is engineered with a wide range of features that make it the ideal choice for rail vehicle connections. Let’s explore some of these features in detail:

| Feature | Benefit |

|---|---|

| Weather-resistant | Built to endure the toughest outdoor conditions, from harsh winters to hot summers, ensuring reliability and longevity in all climates. |

| UV & Ozone resistant | Protects the cable from damage caused by UV radiation and ozone exposure, common in open environments. |

| Fire performance | Flame retardant and self-extinguishing according to IEC 60332-1-2 + EN 60332-1-2, ensuring safety in case of fire and preventing the spread of flames. |

| Oil resistant | Highly resistant to oils, which is crucial for rail systems that operate in oily or greasy environments, prolonging the life of the cable. |

| Torsion angle: +/- 15° | Specifically designed to handle continuous twisting motions without losing performance, making it perfect for the dynamic nature of bogie-to-body connections. |

| Halogen-free | Complies with IEC 60754-1 + VDE 0482-754-1, meaning no harmful substances are released in case of fire, ensuring environmental safety and compliance with RoHS directives. |

| Temperature range: -50°C to +85°C | Performs reliably in extreme temperatures, from cold winter mornings to scorching summer days, making it ideal for use across all regions. |

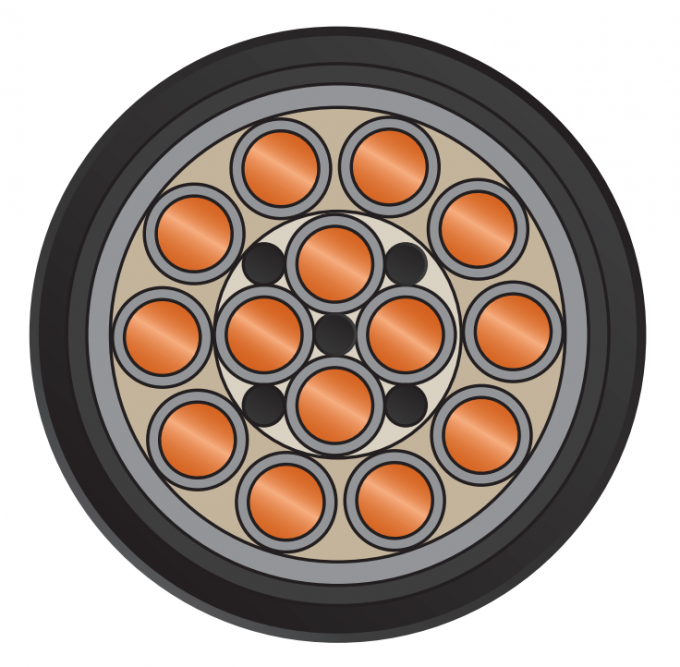

The Twisting and Torsion Connection Cable stands out for its superior construction, designed to handle the rigors of rail transportation. Here’s a breakdown of its key components:

Material: Tinned copper strands as per IEC 60228 and VDE 0295, class 6.

Benefit: Tinned copper provides excellent corrosion resistance, ensuring the cable performs well in moist or high-corrosion environments often encountered in rail operations.

Material: Thermoplastic Elastomer (TPE).

Benefit: TPE insulation is highly flexible, durable, and resistant to mechanical stress, ensuring the cable can handle frequent movements without degrading.

Material: Polyurethane (PUR), compliant with EN 50363-10-2 and VDE 0207-363-10-2.

Benefit: The PUR sheath offers exceptional resistance to abrasion, oils, UV radiation, and ozone, making it ideal for outdoor and high-stress applications.

Description: Stranded in layers, ensuring flexibility and minimizing the risk of internal damage during twisting motions.

Benefit: Layered stranding offers superior flexibility, allowing the cable to move freely without placing undue stress on the conductors.

Color: Black (RAL 9005).

Benefit: The black sheath is UV resistant, ensuring it doesn’t degrade or fade when exposed to sunlight over long periods.

Description: Black cores with consecutive numbering according to EN 50334 + VDE 0293-334, with a green-yellow earth wire from 3 cores.

Benefit: Clear identification of cores ensures easy installation and maintenance, reducing downtime.

When choosing a cable, technical specifications are vital. Here’s a quick overview of the technical data for the Twisting and Torsion Connection Cable:

| Parameter | Details |

|---|---|

| Nominal voltage | Uo/U 300/500 V |

| Testing voltage | Core/core: 2000 V |

| Min. bending radius (fixed) | 4 x d |

| Min. bending radius (flexible) | 6 x d |

| Temperature range (fixed) | -50°C to +85°C |

| Temperature range (flexible) | -40°C to +85°C |

| Torsion angle | +/- 15° |

| Halogen-free | Yes, acc. to IEC 60754-1 + VDE 0482-754-1 |

| Fire performance | Flame retardant and self-extinguishing, acc. to IEC 60332-1-2 + VDE 0482-332-1-2 |

| Oil resistance | Very good, TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| UV & ozone resistance | Good |

| Weather resistance | Good |

These technical attributes ensure that the Twist-Proof Cable performs excellently under the challenging conditions typical of rail systems.

The Twisting and Torsion Connection Cable is ideal for use in various rail vehicle applications, where reliability and durability are essential. Some key use cases include:

| Application | Description |

|---|---|

| Bogie to Vehicle Body | Connects the bogie to the vehicle body, handling frequent twists and mechanical stress during travel and acceleration. |

| Power Transmission | Delivers power from the main supply to vital components of the rail vehicle, ensuring consistent and uninterrupted performance. |

| Signal and Control Systems | Ensures reliable transmission of signals between components, enabling efficient control of rail vehicle operations. |

| Data Transmission | Facilitates the transmission of data for monitoring and diagnostic systems in modern rail vehicles. |

Customizable: Available with or without earth wire, depending on the specific requirements of the application.

Highly durable: Constructed to resist environmental factors such as extreme weather, oils, and mechanical wear.

The Twist-Proof Cable is not only designed for superior performance but also complies with stringent safety and environmental standards:

| Compliance | Description |

|---|---|

| Halogen-free | No harmful halogens, ensuring no toxic gases are released in case of fire, improving passenger safety and complying with IEC 60754-1 + VDE 0482-754-1. |

| RoHS Compliant | Free from restricted substances such as lead, mercury, and cadmium, ensuring compliance with EU environmental directives. |

| Fire Safety | Flame retardant and self-extinguishing as per IEC 60332-1-2 + VDE 0482-332-1-2, reducing the spread of fire and providing critical safety. |

Rail transportation systems must run efficiently with minimal interruptions. The Twist-Proof Cable enhances the reliability of rail vehicles by ensuring:

Consistent electrical connections even under dynamic stress.

Long-lasting performance, reducing the need for frequent replacements or repairs.

Safety through its fire-retardant and halogen-free properties.

With the growing demands placed on modern rail systems, cables that can withstand twisting, mechanical stress, and harsh environmental conditions are essential.

The Twisting and Torsion Connection Cable is the perfect choice for operators looking to improve the durability and performance of their rail vehicles.

Choosing the right cable for your rail system is not just about meeting current needs—it's about investing in long-term reliability and performance. The Twisting and Torsion Connection Cable delivers the durability, flexibility, and safety required for modern rail vehicles, making it a critical component in ensuring smooth and uninterrupted rail operations.

For a customized solution tailored to your rail system's unique needs, contact our team today. Whether you’re facing extreme weather, frequent torsion stress, or demanding operational conditions, our Twist-Proof Cable has the solution you need.

By ensuring reliability, safety, and longevity, the Twisting and Torsion Connection Cable is the right choice for any rail vehicle connection system.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.