Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: International Electrical Commission (IEC) standards

Model Number: Automation Robotic Flexible Cables

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Applicable Robot Models: |

ABB/KUKA/FANUC |

Jacket: |

Special Modified PVC |

Product Id: |

A660-2007-T377 |

Conductor Material: |

Copper |

Net Weight: |

12Kg |

Temperature Range: |

-40°C To 105°C |

Durability: |

High |

Product Net Depth: |

15100 Mm |

Conductor: |

Stranded OFC Copper Wire |

Rate Voltage: |

300/500V |

Package: |

100 Meters/roll |

Rated Temperature: |

-10 ℃ ~ 80 ℃ |

Applicable Robot Models: |

ABB/KUKA/FANUC |

Jacket: |

Special Modified PVC |

Product Id: |

A660-2007-T377 |

Conductor Material: |

Copper |

Net Weight: |

12Kg |

Temperature Range: |

-40°C To 105°C |

Durability: |

High |

Product Net Depth: |

15100 Mm |

Conductor: |

Stranded OFC Copper Wire |

Rate Voltage: |

300/500V |

Package: |

100 Meters/roll |

Rated Temperature: |

-10 ℃ ~ 80 ℃ |

In today’s fast-paced world of industrial automation, where machines perform repetitive and precise tasks, the reliability of components like cables is critical. For industries that rely on robotic flexible cables to drive their automation, ensuring durability and resistance to environmental stressors is vital.

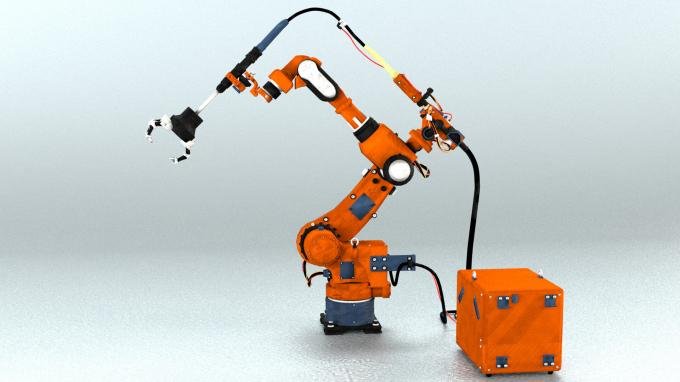

That's where vibration-resistant robotic cables come into play. Our OEM robotic flexible cables are engineered to withstand harsh conditions, including continuous movement, high-flex applications, and significant vibration levels.

Whether you are in factory automation, manufacturing automation, or simply working to improve your robot wiring systems, our flexible industrial automation cables offer the performance and reliability you need.

Robotic flexible cables (also referred to as robot flexible cables, flexible robot cables, or robotic wiring) are specifically designed for industrial applications where continuous motion, flexibility, and durability are critical.

These cables are used in robotic arms, conveyors, and other automated systems that demand high performance under extreme mechanical stress, such as bending, twisting, and vibrations.

Our cables not only meet the mechanical and flexibility requirements but also provide exceptional vibration resistance, ensuring that they do not degrade or fail under constant vibration, which is common in industrial settings.

Vibration Resistance The most significant feature of our vibration-resistant robotic cables is their ability to withstand the stresses caused by continuous vibration.

This is particularly important in industries such as automotive, aerospace, and manufacturing, where machines operate for long hours and are subject to constant motion and vibration. By choosing our vibration-proof cables, you’re ensuring that your automation systems maintain uptime and reduce the need for costly repairs.

High Flexibility Our cables are designed with a high flex life, meaning they can endure millions of flex cycles without compromising performance. This is crucial for robot wiring in environments where machines are constantly moving or adjusting positions.

Chemical Resistance In many industrial environments, cables are exposed to chemicals, oils, and other harsh substances. Our oil and chemical resistant vibration-proof industrial cables are engineered to resist these elements, ensuring a longer lifespan and reduced downtime.

Torsion Resistance For applications where cables experience both bending and twisting, torsion resistance is a must. Our torsion-resistant robot wiring is built to handle complex motions, making it ideal for use in robotic arms and other dynamic systems.

OEM Customization As an OEM robot cable manufacturer, we understand that every industry and application is unique. That’s why we offer custom OEM robot cables for automation that can be tailored to your specific needs, including length, connector type, and resistance properties.

Below is a summary of our industrial automation robotic flexible cables' key specifications:

| Feature | Specification |

|---|---|

| Cable Type | Robotic Flexible Cable |

| Conductor Material | Stranded Copper |

| Insulation | Oil and Chemical Resistant PVC |

| Vibration Resistance | Anti-vibration, shockproof |

| Temperature Range | -40°C to 90°C |

| Bend Radius | Small bend radius for high flexibility |

| Resistance | Oil, chemical, vibration, and torsion |

| Flex Life | Over 10 million flex cycles |

| Customization Options | Available for OEM |

These specifications ensure our robotic flexible cables are equipped to handle a wide variety of industrial automation needs.

Our vibration-resistant robot cables are ideal for a variety of automation and manufacturing applications.

In factory automation, machines must perform repetitive tasks with minimal downtime. The constant vibration from equipment such as conveyors, robotic arms, and other moving components requires robust cabling solutions. Our flexible industrial automation cables ensure reliable performance in these high-stress environments.

Manufacturing environments are known for their harsh conditions, including exposure to chemicals, oils, and extreme temperatures. With our chemical-resistant vibration-proof industrial cables, your manufacturing systems will continue to perform reliably despite the challenging conditions.

Robotics in the automotive industry must operate with precision and reliability. Our torsion-resistant robot wiring ensures that cables can handle the complex motions of robotic systems without succumbing to wear and tear.

In aerospace manufacturing, even the slightest malfunction can result in significant downtime or costly repairs. Our shockproof robotic wiring offers the durability and performance needed to handle the extreme mechanical stresses common in aerospace automation systems.

In automated packaging and material handling systems, cables are subjected to constant motion, vibration, and frequent bending. Our high-flex life vibration-resistant robot cables are designed to endure millions of motion cycles while maintaining performance.

Vibration is one of the most common causes of cable failure in industrial environments. Continuous vibration can wear down the internal structure of cables, causing premature failures, signal interference, or complete breakdowns.

For industries that rely on continuous automation, cable failure can lead to costly downtime and repairs.

Our vibration-resistant robot cables are designed to prevent these issues by using specialized materials and engineering techniques that offer superior vibration resistance.

By choosing vibration-proof cables, you’re protecting your equipment from unnecessary wear and tear, ensuring continuous operation.

| Benefit | Description |

|---|---|

| Reduced Downtime | Minimize cable-related failures due to vibration, saving time and money. |

| Increased Lifespan | Built to withstand harsh conditions, extending the life of your automation systems. |

| Superior Flexibility | High flex life ensures cables can endure millions of flex cycles. |

| Custom OEM Solutions | Tailored to meet your specific automation needs. |

| Chemical and Oil Resistance | Designed for harsh industrial environments where exposure to chemicals and oils is common. |

| Torsion Resistance | Perfect for applications requiring both bending and twisting. |

As an OEM robot cable manufacturer, we understand that one size does not fit all. That’s why we offer fully customizable OEM robot cables for automation. Whether you need a specific connector, additional resistance properties, or a unique length, we can design a cable to meet your exact specifications.

Our team works closely with your engineers and technicians to develop a solution that integrates seamlessly into your systems, providing the performance, reliability, and durability you need to maintain a competitive edge in your industry.

| Cable Type | Vibration Resistance | Flexibility | Chemical Resistance | Torsion Resistance | OEM Customization |

|---|---|---|---|---|---|

| Vibration Resistant Robot Cables | Excellent | High | High | High | Available |

| Standard Robot Cables | Moderate | Moderate | Low | Low | Limited |

| Torsion Resistant Robot Wiring | High | High | High | Excellent | Available |

| Oil and Chemical Resistant Cables | High | Moderate | Excellent | Moderate | Available |

This comparison table highlights the advantages of choosing our vibration-resistant cables over standard cables, particularly for applications involving high movement and vibration.

When it comes to choosing the right cables for industrial automation, durability and performance are key.

Our vibration-resistant robotic flexible cables are designed to handle the toughest environments, ensuring that your automation systems perform optimally without the risk of failure due to vibration, bending, or chemical exposure.

With our customizable OEM solutions, you can have cables tailored to your specific requirements, ensuring seamless integration with your existing systems.

Whether you're in the automotive, aerospace, manufacturing, or packaging industry, our cables offer the reliability, flexibility, and resistance needed to keep your operations running smoothly.

Q1: What is the lifespan of your vibration-resistant cables?

Our cables are designed for a high flex life, withstanding over 10 million flex cycles in demanding environments.

Q2: Can you customize cables for specific industries?

Yes, as an OEM manufacturer, we offer custom OEM robot cables tailored to the specific requirements of your industry.

Q3: Are your cables resistant to chemicals and oils?

Yes, our oil and chemical resistant vibration-proof cables are designed for industrial environments with exposure to harsh substances.

Q4: How do vibration-resistant cables benefit automation systems?

Vibration-resistant robot cables reduce wear and tear caused by constant movement and vibration, ensuring fewer failures and reduced downtime.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.