Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: International Electrical Commission (IEC) standards

Model Number: Flexible Automation Cables

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: 12,000 meters per week

Application: |

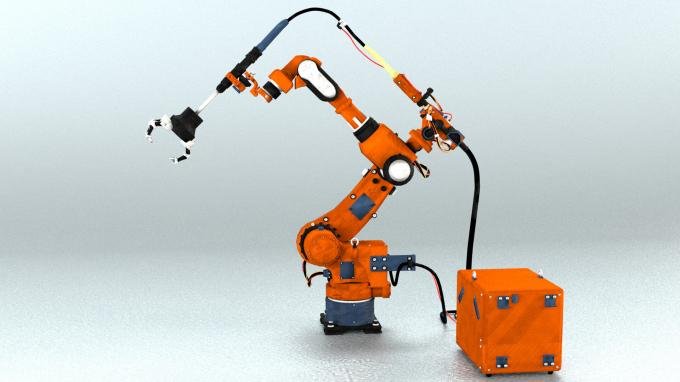

Robotics |

Cost: |

Moderate |

Name: |

Robotic Flexible Cables |

Weight: |

Light |

Application: |

Robotics |

Cost: |

Moderate |

Name: |

Robotic Flexible Cables |

Weight: |

Light |

In the world of automation, choosing the right cables can significantly impact your operations.

Flexible automation cables, specifically designed for robotics and industrial applications, are essential for ensuring smooth and efficient processes.

Our oil and chemical resistant robot wires offer unparalleled flexibility and durability, making them perfect for challenging environments.

This article will explore the features, benefits, and applications of these innovative cables, ensuring you have the knowledge needed to enhance your automation systems.

Flexible automation cables are specifically engineered to withstand dynamic movements and harsh conditions.

They are crucial for robotics and machinery used in industrial environments, particularly in sectors where cables are frequently subjected to bending, twisting, and exposure to chemicals or oils.

Flexible robot cables are a subset of automation cables designed to work seamlessly in robotic applications.

These cables are engineered to handle the demanding motion requirements of robots while maintaining a long lifespan. The flexibility allows for easier installation and integration into robotic systems, ensuring reliable performance under various conditions.

Our oil and chemical resistant robot wires are designed with several key features that set them apart from standard cables:

High Flex Life: Engineered to withstand repeated bending and movement, our cables maintain performance even in dynamic applications.

Oil Resistant: Designed to resist the damaging effects of oils, our cables are suitable for use in environments with high exposure to hydrocarbons.

Chemical Resistant: Constructed with materials that prevent degradation from exposure to various chemicals, ensuring longevity and reliability in harsh environments.

Torsion Resistant: The robust design allows our cables to handle torsional stress without compromising performance, making them ideal for robotic applications.

Versatile Applications: These cables are suitable for various applications, from manufacturing to packaging and beyond.

| Feature | Specification |

|---|---|

| Cable Type | Flexible Automation Cable |

| Conductor Material | High-quality copper |

| Jacket Material | Oil and chemical resistant compounds |

| Operating Voltage | Up to 600V |

| Temperature Range | -40°C to 90°C |

| Flexibility | Highly flexible for continuous motion |

| Chemical Resistance | Excellent against oils and various chemicals |

| Standard Compliance | CE, UL, and RoHS compliant |

These specifications showcase the robust nature of our industrial automation cables, ensuring they can handle the demands of various applications.

Enhanced Durability

One of the primary advantages of our flexible automation wires is their durability. The materials used in their construction ensure that they can withstand exposure to oils and chemicals without significant degradation. This durability translates into fewer cable replacements, reducing downtime and maintenance costs.

Improved Flexibility

The flexibility of our robotic wiring allows for easy routing and installation in complex systems. This adaptability is crucial in robotic applications where space is limited, and movement is dynamic.

Longer Lifespan

Thanks to their resistance to harsh conditions, our chemical resistant industrial automation cables often have a longer lifespan compared to standard cables. This longevity is a significant factor in reducing overall operational costs.

Safety Compliance

Our cables meet stringent safety standards, ensuring that they are safe to use in various industrial applications. Compliance with CE, UL, and RoHS standards means you can trust our cables to perform safely in your operations.

Versatile Applications

From manufacturing to food processing, our oil and chemical resistant robot wires can be used across various industries. Their versatility makes them an excellent choice for businesses looking to optimize their operations.

Manufacturing

In manufacturing environments, robotic systems are often exposed to oils and chemicals. Using our oil resistant robot cables for harsh environments ensures reliable performance without frequent replacements.

Food Processing

The food industry requires cables that can withstand cleaning agents and moisture. Our flexible industrial cables are designed to meet these requirements, ensuring compliance with health and safety regulations.

Chemical Processing

In chemical processing plants, cables must resist harsh chemicals. Our chemical resistant industrial automation cables provide the necessary protection to maintain operational integrity.

Automotive Industry

Robotics play a vital role in automotive manufacturing, where exposure to various oils and chemicals is common. Our flexible robot cables are ideal for these applications, ensuring seamless performance.

Pharmaceutical Industry

The pharmaceutical sector requires high standards for cleanliness and safety. Our robot cables are designed to meet these requirements, ensuring reliability in sensitive environments.

When selecting robot cables for your applications, it's essential to understand the differences between various types available in the market. The following table provides a comparison between our flexible automation cables and standard cables.

| Feature | Flexible Automation Cables | Standard Cables |

|---|---|---|

| Flex Life | High (up to 10 million cycles) | Low (1 million cycles) |

| Oil Resistance | Excellent | Poor |

| Chemical Resistance | High | Moderate |

| Torsion Resistance | Excellent | Low |

| Installation Ease | High flexibility for routing | Limited flexibility |

| Cost | Higher initial investment | Lower initial cost |

This comparison highlights the superior qualities of our flexible automation cables in terms of performance and reliability, justifying the investment for demanding applications.

Case Study 1: Automotive Manufacturing

In an automotive assembly plant, robotic arms were used for painting and assembly tasks. The existing cables failed due to exposure to paint and solvents, leading to frequent downtime. By switching to our oil and chemical resistant robot wires, the plant saw a 40% reduction in cable replacements and improved overall efficiency.

Case Study 2: Food Processing Plant

A food processing facility needed cables that could withstand frequent cleaning and exposure to moisture. Our flexible industrial cables not only met the safety requirements but also performed reliably under harsh conditions, resulting in enhanced productivity and compliance with health standards.

Understanding the safety standards related to cables is crucial for ensuring operational safety. Our flexible automation cables comply with:

CE Certification: Ensures compliance with European health and safety regulations.

UL Certification: Guarantees safety and performance standards in the U.S. market.

RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment.

These certifications assure users of the quality and safety of our robot wiring, making them a reliable choice for industrial applications.

When considering the purchase of flexible robot cables, it’s essential to source them from reputable suppliers. Look for suppliers who can provide:

Customization Options: The ability to tailor cables to your specific requirements.

Technical Support: Availability of experts to assist with installation and troubleshooting.

Warranty and Support: Assurance of product quality through warranties and customer support.

Choosing the right cables for your robotic and automation systems is crucial for maintaining efficiency and safety in your operations. Our flexible automation cables, specifically designed as oil and chemical resistant robot wires, provide the ideal solution for demanding environments.

With their superior durability, flexibility, and compliance with safety standards, our cables can enhance your operations across various industries. From manufacturing to food processing, investing in high-quality flexible robot cables ensures that your systems run smoothly, reducing downtime and maintenance costs.

Contact us today to learn more about our products and how we can assist you in selecting the best cables for your needs. Your automation solutions deserve the best, and we are here to provide it.

RFQ: Common Questions and Answers

Q1: What are the main advantages of using flexible robot cables?

Flexible robot cables offer superior durability, flexibility, and resistance to oils and chemicals, ensuring reliable performance in demanding applications.

Q2: Are these cables customizable?

Yes, we provide customization options to meet specific requirements for various industrial applications.

Q3: What industries can benefit from using your robot wires?

Our robot wires are suitable for various industries, including manufacturing, food processing, automotive, and pharmaceuticals.

Q4: How do I ensure the cables are safe for use in my application?

Our cables comply with CE, UL, and RoHS standards, ensuring they meet the necessary safety regulations for industrial use.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.