Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: DiN VDE 0295 Class 5 & DiN VDE 0207

Model Number: Tunnel Boring Machine Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Dynamic Installation: |

Adaptable To Various Setups |

Infrastructure Support: |

Vital For Tunneling Projects |

Mining Innovation: |

Adapts To Evolving Technology |

TBM Efficiency: |

Enhances Machine Performance |

Flame Resistance: |

Superior Fire Safety |

Tunnel Construction: |

Tailored For Tunnel Projects |

Long Lifespan: |

Ensures Enduring Durability |

Corrosion Resistance: |

Endures Tunnel Environments |

Dynamic Installation: |

Adaptable To Various Setups |

Infrastructure Support: |

Vital For Tunneling Projects |

Mining Innovation: |

Adapts To Evolving Technology |

TBM Efficiency: |

Enhances Machine Performance |

Flame Resistance: |

Superior Fire Safety |

Tunnel Construction: |

Tailored For Tunnel Projects |

Long Lifespan: |

Ensures Enduring Durability |

Corrosion Resistance: |

Endures Tunnel Environments |

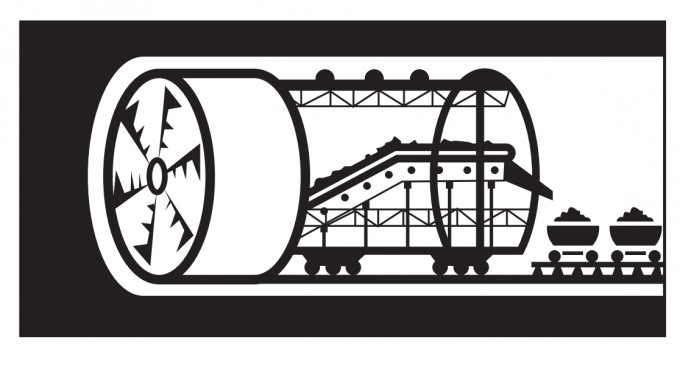

When it comes to tunneling operations, the tunnel boring machine (TBM) is one of the most crucial pieces of equipment.

TBMs are responsible for cutting through solid rock, soil, and other tough materials, making them an essential tool in infrastructure projects like subway construction, road tunnels, and underground water systems.

However, these machines need reliable, durable, and highly efficient cables to power them. Enter the High Conductivity Tunnel Boring Machine Cable Low Smoke Zero Halogen (LSZH).

This cable is specifically designed to provide high levels of conductivity while adhering to safety regulations, making it an ideal solution for tunnel boring and other underground applications. Let's dive deeper into the benefits, features, and specifications of this TBM cable and understand why it's the go-to choice for such heavy-duty environments.

In tunneling operations, power efficiency is key. The high energy demand of TBMs means that high conductivity in cables is critical. These cables are designed to minimize power loss and ensure the efficient transmission of electricity over long distances. This translates into cost savings and more reliable operations.

A high conductivity cable means reduced resistance, which keeps energy loss to a minimum. This also ensures that the machine operates at peak performance without unnecessary power strain. It's not just about keeping the machine running—it's about maximizing efficiency while minimizing costs.

| Specification | Value |

|---|---|

| Material | Copper or Aluminum |

| Conductivity | High Conductive |

| Operating Voltage | 1kV to 35kV |

| Max Current Capacity | Up to 5000A |

| Resistance | Low |

One of the most important considerations in any underground or enclosed operation is safety. The Low Smoke Zero Halogen (LSZH) feature ensures that these cables emit minimal smoke and no harmful halogen gases when exposed to fire.

This is crucial for environments like tunnels, where visibility and air quality are essential for both human safety and operational efficiency.

In traditional cables, materials like PVC emit thick, toxic smoke when burned. In contrast, LSZH cables release far less smoke and contain no halogens, reducing the risk of toxic exposure and improving escape conditions in case of a fire. For this reason, LSZH cables are now considered the gold standard for underground operations.

| Feature | Benefit |

|---|---|

| Low Smoke | Improved visibility during emergencies |

| Zero Halogen | No toxic halogen gases during combustion |

| Fire Retardant | Slows down fire spread |

| Complies with Safety Standards | Meets international safety regulations |

The primary use of High Conductivity TBM Cables is in tunneling operations, but they can also be used in various other underground or heavy-duty applications. Here's a list of the most common uses:

Tunneling Machines (TBMs): The cable’s flexibility and high power capacity make it perfect for powering these large machines.

Underground Mining: These cables are ideal for powering mining machinery in deep underground environments, where safety and efficiency are critical.

Subway Construction: Subways require extensive tunneling, making this cable an important part of construction operations.

Road and Utility Tunnels: Long-distance tunnels for utilities like water, power, and telecommunications also benefit from the high conductivity and safety features of these cables.

| Application | Cable Feature |

|---|---|

| Tunnel Boring Machines | High conductivity, LSZH |

| Underground Mining Equipment | Low resistance, flame retardant |

| Subway Construction | Flexible, high current capacity |

| Utility and Road Tunnels | Durable, halogen-free |

Every tunneling or mining project is different. Whether you're working with soil, rock, or mixed terrain, each environment presents its own set of challenges. That's why customizable TBM cables are often the preferred solution.

These cables can be tailored to fit the specific voltage, length, and environmental demands of a project.

For example, projects that require deep tunneling may need a long-length low resistance cable to ensure power transmission over extended distances. Similarly, environments with high moisture or chemical exposure might benefit from cables with additional chemical resistance and waterproofing features.

Length Adjustments: Custom lengths for specific project needs.

Material Choices: Copper or aluminum options depending on conductivity requirements.

Insulation and Sheathing: LSZH, flame retardant, or chemical-resistant options.

Operating Voltage: Custom voltage ratings based on the application.

| Customization Option | Benefit |

|---|---|

| Cable Length | Tailored to project-specific distances |

| Conductor Material | Choose between copper or aluminum |

| Insulation Type | LSZH or flame-retardant |

| Voltage Range | Custom voltage ratings |

Underground environments are known for their harsh conditions. Whether it’s the high pressure, moisture, chemicals, or extreme temperatures, the cable you use must be tough enough to handle it all.

The High Conductivity Tunnel Boring Machine Cable is designed with durability in mind, ensuring reliable operation even in the most demanding conditions.

Many tunnel projects face the risk of cable wear and tear due to the rough conditions. With this durable TBM cable, you can count on a longer lifespan and reduced maintenance costs.

The cable’s flame-retardant and halogen-free properties add an extra layer of protection, making it ideal for environments with potential fire hazards.

If you’re involved in tunneling operations or other underground projects, choosing the right cable can make or break your operation. The High Conductivity Tunnel Boring Machine Cable Low Smoke Zero Halogen provides the perfect balance of power efficiency, safety, and durability.

Its high conductivity ensures minimal energy loss, while the LSZH feature protects workers and equipment in case of fire.

Whether you need a TBM cable for a subway project or an underground mining operation, this cable offers the performance and safety you need.

Plus, with customizable options available, you can tailor the cable to meet the specific demands of your project.

| Key Features | Benefits |

|---|---|

| High Conductivity | Efficient power transmission |

| Low Smoke Zero Halogen (LSZH) | Enhanced safety in case of fire |

| Customizable Options | Tailored solutions for unique projects |

| Durable and Flexible | Long-lasting, reliable performance |

By investing in the High Conductivity TBM Cable, you can rest assured that your tunneling operations will run smoothly and efficiently, with minimal downtime and maximum safety.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.