Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Armoured TBM Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Flame Resistance: |

Superior Fire Safety |

Rail Tunneling: |

Essential For Rail Projects |

Urban Expansion: |

Facilitates City Growth |

Certified Compliance: |

Meets Safety Standards |

High Conductivity: |

Optimal Power Transmission Efficiency |

Low Smoke Emission: |

LSZH Insulation Minimizes Smoke |

Heavy-Duty Performance: |

Suited For Demanding Tasks |

Excavation Safety: |

Minimizes Fire Risks |

Flame Resistance: |

Superior Fire Safety |

Rail Tunneling: |

Essential For Rail Projects |

Urban Expansion: |

Facilitates City Growth |

Certified Compliance: |

Meets Safety Standards |

High Conductivity: |

Optimal Power Transmission Efficiency |

Low Smoke Emission: |

LSZH Insulation Minimizes Smoke |

Heavy-Duty Performance: |

Suited For Demanding Tasks |

Excavation Safety: |

Minimizes Fire Risks |

In the realm of tunnel construction and subterranean boring, the importance of reliable and durable electrical cables cannot be overstated. Among the various types of cables, armoured TBM cables stand out as a vital component for powering tunneling machines (TBMs) used in challenging underground environments.

This article delves into the essential features, benefits, and applications of armoured TBM cables, illuminating why they are the go-to choice for construction projects beneath the earth's surface.

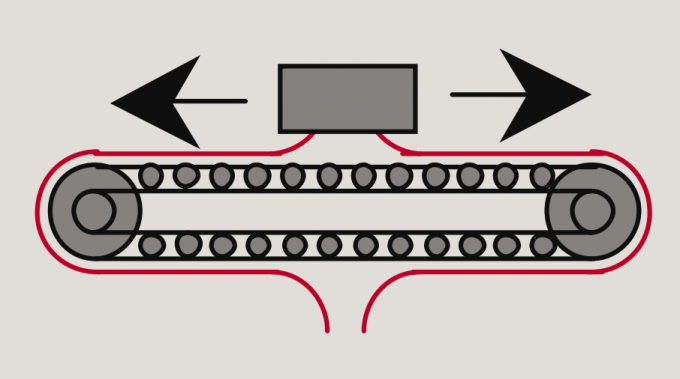

TBM cables are specially designed to withstand the unique challenges posed by underground construction.

These cables provide electrical power to tunneling machines, ensuring the smooth operation of various components essential for excavation and construction. The armoured variant of TBM cables adds an extra layer of protection, making them suitable for harsh environments.

| Feature | Description |

|---|---|

| Armoured Protection | Shielding against mechanical damage, impacts, and abrasions. |

| Flexibility | Designed for tight spaces, allowing for easy installation. |

| Chemical Resistance | Ability to withstand harsh chemicals often found underground. |

| Water Resistance | Watertight properties prevent water ingress, essential in wet conditions. |

| High Voltage Rating | Capable of handling the demands of high-power tunneling equipment. |

The armouring in TBM cables serves several critical functions. First and foremost, it provides protection against mechanical damage that may occur during installation or operation. Tunneling projects often involve significant physical stress and potential hazards, such as rockfalls and equipment collisions.

The armoured layer ensures that the cables remain intact and functional, preventing costly downtime.

Moreover, these cables are designed to be flexible, allowing them to navigate the tight confines of tunnels. This flexibility is crucial for adapting to the dynamic environment of a tunneling project, where space is limited, and maneuverability is key.

Armoured TBM cables are used across various applications within the tunneling industry. Here are some of the most common scenarios where these cables play an essential role:

Subterranean Boring: In the process of subterranean boring, armoured TBM cables provide the necessary power to boring machines, facilitating efficient drilling through challenging geological formations.

Underground Construction: Whether for roadways, railways, or utilities, these cables are indispensable in any project that involves underground excavation.

Infrastructure Development: Large infrastructure projects often require extensive tunneling. Armoured TBM cables ensure that power supply remains consistent, contributing to the overall success of the project.

Mining Operations: In mining, armoured cables are essential for powering equipment used in underground mining operations, ensuring safety and reliability.

When selecting armoured TBM cables, it's crucial to consider the specifications that match the project's demands. Below is a summary of typical specifications that clients might look for:

| Specification | Value |

|---|---|

| Conductor Material | Copper or Aluminum |

| Voltage Rating | Up to 1,000V |

| Cable Type | Multi-core or Single-core |

| Temperature Range | -40°C to +90°C |

| Armouring Type | Steel wire or tape |

| Weight | Varied depending on cable size and type |

Utilizing armoured TBM cables provides several key benefits that are crucial for the success of tunneling projects. Here’s a closer look at these advantages:

Durability: The robust construction of armoured cables enhances their lifespan, reducing the frequency of replacements and maintenance.

Safety: With enhanced protection against damage, these cables contribute to a safer working environment for underground workers, minimizing electrical hazards.

Performance: Armoured TBM cables are designed to maintain performance even in extreme conditions, ensuring that tunneling operations proceed without interruption.

Cost-Effectiveness: By reducing downtime and maintenance costs, the initial investment in high-quality armoured cables can lead to substantial savings over the project lifecycle.

When deciding between armoured and unarmoured TBM cables, understanding their differences is essential. Here’s a comparison that outlines the key distinctions:

| Feature | Armoured TBM Cables | Unarmoured TBM Cables |

|---|---|---|

| Protection Level | High, resistant to impact and abrasion | Lower, less resistant to external damage |

| Flexibility | Moderately flexible | Highly flexible |

| Weight | Heavier due to armouring | Lighter |

| Cost | Generally more expensive | Usually less expensive |

| Applications | Harsh environments | Less demanding environments |

Safety is paramount in tunneling operations. Armoured TBM cables must comply with various safety standards to ensure their reliability and effectiveness. Here are some of the key standards relevant to these cables:

ISO 9001: Quality management systems.

IEC 60502-1: Standard for power cables with extruded insulation.

EN 50363: Standard for flexible cables used in industrial applications.

BS 7889: Specification for cables for use in hazardous areas.

These standards help guarantee that armoured TBM cables meet the stringent requirements necessary for safe operation in underground conditions.

To illustrate the effectiveness of armoured TBM cables, let’s explore a few case studies showcasing their successful implementation in real-world projects.

Project A: Urban Railway Tunnel

In a major urban railway project, armoured TBM cables were used to power tunneling machines through challenging geological conditions. The cables withstood significant mechanical stress and moisture, ensuring continuous operation and timely project completion.

Project B: Water Supply Tunnel

During the construction of a water supply tunnel, the use of watertight armoured TBM cables prevented water ingress and electrical failures. This project highlighted the importance of selecting the right cable type for specific environmental challenges.

Project C: Mining Expansion Project

In a mining operation, the adoption of corrosion-resistant armoured cables significantly improved operational efficiency. These cables not only powered the machines effectively but also reduced maintenance needs in the harsh underground conditions.

For those wondering, where to buy armoured TBM cables for tunnel construction, several reputable manufacturers and suppliers offer high-quality products tailored to specific project needs.

It's advisable to consult with industry experts or local distributors to find the right cable that meets the safety and performance standards required for tunneling projects.

The construction industry is evolving, with a growing emphasis on sustainability and efficiency. As tunneling projects continue to increase in complexity, the demand for reliable, high-performance armoured TBM cables will only grow. These cables serve as the backbone of tunneling operations, enabling successful completion in challenging environments.

By investing in quality armoured TBM cables, construction companies can ensure safety, efficiency, and longevity in their tunneling projects. As technology advances, we can expect further innovations in cable design and construction, paving the way for even more robust solutions for the tunneling industry.

What are armoured TBM cables used for?

Armoured TBM cables are used to power tunneling machines in underground construction and boring operations, providing reliable electricity in harsh environments.

What benefits do armoured cables provide?

Armoured cables offer durability, safety, and improved performance in extreme conditions, reducing the need for frequent maintenance and replacements.

How do I choose the right TBM cable for my project?

When selecting a TBM cable, consider factors like environmental conditions, voltage requirements, and compliance with safety standards to ensure optimal performance.

In summary, armoured TBM cables are indispensable in the world of tunnel construction, providing the strength, flexibility, and reliability needed to conquer the subterranean challenges that lie beneath our cities and landscapes.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.