Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Tunnel Boring Machine TBM Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Low Smoke Emission: |

LSZH Insulation Minimizes Smoke |

Application: |

Tunnel Boring Machine |

Flame Resistance: |

Superior Fire Safety |

Dust-Resistant Design: |

Maintains Cleanliness In Tunnels |

Dynamic Installation: |

Adaptable To Various Setups |

Mining Innovation: |

Adapts To Evolving Technology |

Insulation Material: |

Polyethylene |

Long Lifespan: |

Ensures Enduring Durability |

Low Smoke Emission: |

LSZH Insulation Minimizes Smoke |

Application: |

Tunnel Boring Machine |

Flame Resistance: |

Superior Fire Safety |

Dust-Resistant Design: |

Maintains Cleanliness In Tunnels |

Dynamic Installation: |

Adaptable To Various Setups |

Mining Innovation: |

Adapts To Evolving Technology |

Insulation Material: |

Polyethylene |

Long Lifespan: |

Ensures Enduring Durability |

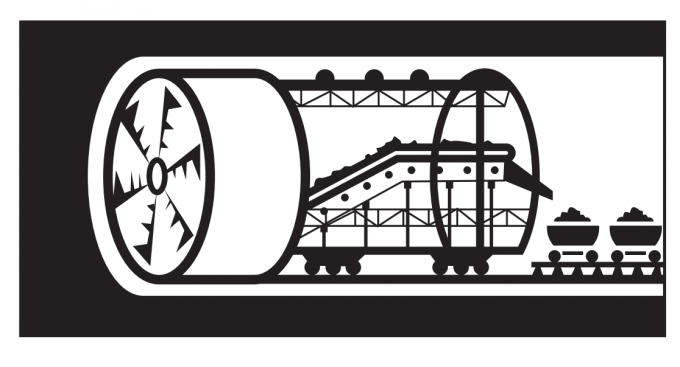

In the dynamic world of mining, efficiency and safety are paramount. One critical component in ensuring both is the Tunnel Boring Machine (TBM) cable.

These cables power the heavy-duty machinery that digs through earth and rock, making them essential for successful mining operations. In this article, we will explore the benefits and features of TBM cables, specifically those with polyethylene insulation designed for mining environments.

Tunnel Boring Machines are advanced tools designed to excavate tunnels through various terrains. Unlike traditional methods that often involve blasting or drilling, TBMs create smooth and stable tunnels, minimizing the environmental impact.

They are widely used in both urban infrastructure projects and mining operations.

Types of TBMs: There are several types of TBMs, including:

Earth Pressure Balance Machines (EPBM)

Slurry Shield Machines

Open-Face Machines

These machines have revolutionized the way tunnels are constructed, allowing for greater precision and reduced downtime.

TBM cables are specifically designed to handle the demanding environments of mining operations. They connect power sources to TBMs, ensuring that all components of the machine function optimally.

This includes the cutter heads, hydraulic systems, and support mechanisms.

Key Characteristics of TBM Cables:

High Flexibility: TBM cables need to navigate tight spaces and curves within tunnels. Flexibility is crucial for preventing damage during operation.

Durability: These cables must withstand harsh mining conditions, including moisture, dirt, and mechanical stress.

Safety Standards: Compliance with safety regulations is essential in mining operations. TBM cables must meet rigorous safety standards to prevent accidents.

Polyethylene insulation plays a vital role in enhancing the performance of TBM cables. Here are some benefits of using cables with this type of insulation:

Chemical Resistance: Polyethylene is resistant to many chemicals, making it suitable for use in environments where exposure to harmful substances is a concern.

Temperature Tolerance: PE insulated cables can handle a wide range of temperatures, ensuring reliable performance even in extreme conditions.

Low Smoke and Halogen-Free Options: In the event of a fire, polyethylene sheathed cables produce minimal smoke and do not emit harmful halogens, enhancing safety for workers.

TBM cables with polyethylene insulation are ideal for various mining applications, including:

Underground Mining: They provide reliable power supply to TBMs working beneath the surface, where conditions can be challenging.

Material Handling: TBM cables facilitate the operation of equipment that transports mined materials to the surface.

Construction of Shafts: These cables are essential for powering equipment used in the construction of vertical mine shafts.

| Application Area | Benefits of PE Insulated TBM Cable |

|---|---|

| Underground Mining | Flexible and resistant to harsh conditions |

| Material Handling | Reliable power for efficient operations |

| Construction of Shafts | Safety and performance under pressure |

When selecting TBM cables for mining, it’s essential to consider their specifications. Below is a comparison table of typical technical features:

| Feature | PE Insulated TBM Cable | PVC Insulated TBM Cable |

|---|---|---|

| Flexibility | High | Moderate |

| Temperature Range | -40°C to +90°C | -20°C to +70°C |

| Chemical Resistance | Excellent | Moderate |

| Flame Resistance | Low Smoke Zero Halogen | Varies |

| Typical Applications | Mining, Tunneling | General Purpose |

The choice of polyethylene insulated TBM cables is not just about compliance; it's about enhancing operational efficiency and safety. Here are several reasons why these cables should be a top consideration for mining operations:

Increased Reliability: PE insulated cables are known for their durability and reliability, ensuring that your TBM operates continuously without unnecessary interruptions.

Enhanced Safety: Given the hazardous nature of mining, choosing cables that minimize risks related to fire and chemical exposure is critical. Polyethylene's low smoke and halogen-free characteristics provide an added layer of safety.

Customizability: Many manufacturers offer custom solutions tailored to specific mining environments. This flexibility allows operations to choose cables that best suit their needs, whether for harsh outdoor conditions or confined underground spaces.

Cost-Effectiveness: While upfront costs might be higher, the long-term durability and reliability of polyethylene insulated TBM cables can lead to lower maintenance costs and reduced downtime.

Case Study 1: A major mining operation in South America faced frequent cable failures due to harsh chemical exposure. By switching to polyethylene insulated TBM cables, they reduced cable replacement costs by 30% and improved overall efficiency.

Case Study 2: An urban tunneling project in Australia implemented flexible PE jacketed tunneling machine cables to navigate tight corners. This led to faster installation times and minimized disruptions to surrounding areas.

Compliance with safety standards is a must for all TBM cables used in mining operations.

Regulations such as those established by the Mine Safety and Health Administration (MSHA) and Australian/New Zealand standards (AS/NZS) set the benchmarks for cable performance.

| Standard | Description |

|---|---|

| MSHA | Ensures safety in mining operations |

| AS/NZS | Sets quality benchmarks for cables |

| IEC Standards | International standards for cable safety |

In conclusion, investing in polyethylene insulated TBM cables is a smart move for any mining operation. These cables offer the necessary flexibility, durability, and safety features to ensure successful tunneling and excavation projects. As mining continues to evolve, embracing technology and high-quality components will be essential for staying ahead of the competition.

Ready to enhance your mining operations with the best TBM cables on the market?

Contact us today to learn more about our polyethylene insulated TBM cables and how they can benefit your projects. Don't settle for less; choose quality and reliability in your tunneling endeavors.

This article has highlighted the importance of selecting the right TBM cables for mining operations, particularly those with polyethylene insulation. With the right knowledge and resources, mining companies can ensure safe, efficient, and successful operations underground.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.