Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™ Mining

Certification: VDE 0250 Part 813

Model Number: PROTOLON (M) R-(N)TSCGEWOEU LWL 3.6/6KV

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Rated: |

8kV |

Flexible: |

Yes |

Voltage Rating: |

1.8/3 KV |

Abrasion Resistant: |

Yes |

Armored: |

Galvanized Steel Wire Or Tape |

Insulation Material: |

EPR (Ethylene Propylene Rubber) |

Flexibility: |

Flexible |

Temperature Rating: |

-25°C To +60°C |

Compact Design: |

Space-efficient Construction. |

Abrasion Resistance: |

High |

Rated: |

8kV |

Flexible: |

Yes |

Voltage Rating: |

1.8/3 KV |

Abrasion Resistant: |

Yes |

Armored: |

Galvanized Steel Wire Or Tape |

Insulation Material: |

EPR (Ethylene Propylene Rubber) |

Flexibility: |

Flexible |

Temperature Rating: |

-25°C To +60°C |

Compact Design: |

Space-efficient Construction. |

Abrasion Resistance: |

High |

The Feichun PROTOLON (M) R-(N)TSCGEWOEU LWL 3.6/6KV Reeling Cable is engineered for industrial excellence. Designed for connection of large material handling machines such as excavators, dumpers, and mobile crushers in open-cast mines, this cable handles high mechanical stresses and works seamlessly with mono-spiral and cylindrical reels.

With a robust design, advanced material composition, and integrated fiber-optic technology, it sets new standards for reliability and efficiency in harsh environments.

The PROTOLON cable is positioned as a high-performance solution for the mining industry, delivering durability, flexibility, and precision. It meets stringent safety and performance standards, ensuring uninterrupted operation in demanding industrial applications.

Excavator systems in mining operations

Mobile crushers for large-scale material processing

Dumpers in rugged terrains

Integration with mono-spiral and cylindrical reels for optimal cable management

The cable integrates effortlessly into existing machinery setups, offering reliable power transmission and data communication through its fiber-optic elements, enhancing operational efficiency and reducing downtime.

| Feature | Specification |

|---|---|

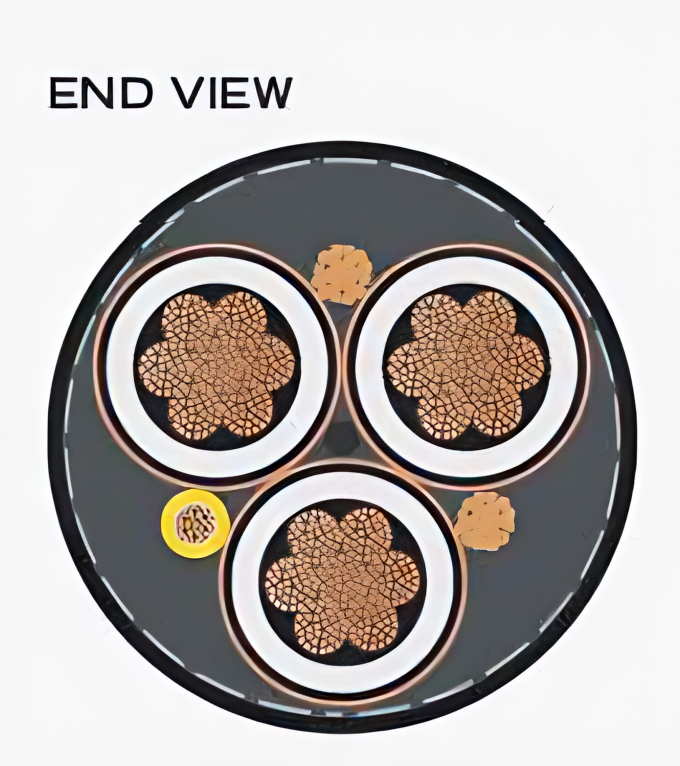

| Core Design | Triple-core configuration (25mm² to 300mm²) |

| Earth Conductor | Split design for enhanced grounding |

| Fiber Optic Elements | Integrated within interstices for reliability |

| Semi-conducting Layer | Inner and outer layers for optimal insulation |

| Component | Material |

| Conductor | Very finely stranded copper, class FS |

| Insulation | EPR rubber (special compound > 3GI3) |

| Inner Sheath | Rubber, special compound 5GM3 |

| Outer Sheath | Polychloroprene (PCP), special compound > 5GM5 |

| Armoring | Braiding with polyester reinforcement |

| Parameter | Value |

| Operating Voltage | 3.6/6 (7.2) kV |

| Test Voltage | 11 kV |

| Nominal System Voltage | 6000 V |

| Condition | Temperature (°C) |

| Max. Conductor Temp. | 90 |

| Short Circuit Temp. | 250 |

| Installation Temp. (Fix) | -40 to 80 |

| Installation Temp. (Flex) | -35 to 80 |

| Fiber Type | Multi-mode Graded Index | Single-mode Graded Index |

| Cladding Diameter | 125 μm | 125 μm |

| Fiber Diameter | 250 μm | 250 μm |

| Bandwidth (850 nm) | > 400 MHz | - |

| Bandwidth (1310 nm) | > 600 MHz | > 1200 MHz |

| Parameter | Value |

| Attenuation at 850 nm | < 3.3 dB/km |

| Attenuation at 1310 nm | < 0.9 dB/km |

| Chromatic Dispersion | < 3.5 ps/nm·km at 1300 nm |

| Feature | Property |

| Flame Retardant | EN/IEC 60332-1-2 |

| Oil Resistance | Yes |

| UV Resistance | Yes |

| Sea Water Resistance | Yes |

| Ozone Resistance | Yes |

| Core Size (mm²) | Earth Conductor (mm²) | Fiber Optics Integration |

| 25 | 25 | LWL |

| 50 | 50 | LWL |

| 95 | 50 | LWL |

| 300 | 150 | LWL |

Assess Load Requirements: Ensure the selected cable meets the machine’s power demands.

Evaluate Environmental Conditions: Consider UV exposure, temperature extremes, and chemical resistance needs.

Installation Method Impact: Verify compatibility with reel systems and routing requirements.

| Requirement | Specification |

| Bending Radius | 6xD (fixed), 10xD (flexible), 20xD (S-type changes) |

| Torsional Stress | +/- 100°/m |

| Tensile Strength | 20 N/mm² (static), 25 N/mm² (dynamic) |

| Feature | Specification |

| Travel Speed | 100 m/min (rewinding), 120 m/min (reeling) |

| Directional Changes | Accommodates frequent changes |

The PROTOLON cable series complies with international standards, including:

EN 50525-2-21

DIN VDE 0207-21

DIN VDE 0298-3

GOST Fire Certificate of Russian Federation

IEC 60332-1-2 for fire safety

Regular Inspections: Check for wear and tear.

Performance Monitoring: Ensure consistent signal transmission.

Lubrication: Maintain reel system efficiency.

Common Issues: Address bending fatigue and torsional stress promptly.

Diagnostic Procedures: Use thermal imaging and fiber-optic signal testing.

Technical Documentation: Comprehensive installation guides

Training Materials: On-site and virtual training programs

Contact Information: 24/7 support hotline

The Feichun PROTOLON 3.6/6KV reeling cable represents the future of mining and material handling connectivity. With evolving technologies and growing industrial demands, it remains a reliable solution for power and data needs, ensuring efficient and safe operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.