Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: British standard; BS6708

Model Number: BS 6708 TYPE 7 EPR Rubber Mining Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Jacket Material: |

Neoprene |

Flexibility: |

Excellent |

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

Voltage Rating: |

0.64/1.1kV |

Jacket: |

Rubber |

Sheath Material: |

Chlorinated Polyethylene (CPE) |

Jacket Material: |

Neoprene |

Flexibility: |

Excellent |

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

Voltage Rating: |

0.64/1.1kV |

Jacket: |

Rubber |

Sheath Material: |

Chlorinated Polyethylene (CPE) |

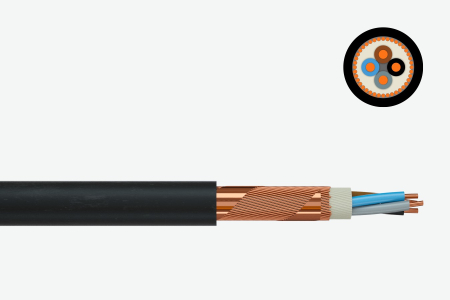

The BS 6708 TYPE 7 Rubber Mining Cable (Резиновый горный кабель BS 6708 TYPE 7) is designed for use in harsh mining environments.

It is suitable for power distribution in underground mines, open-pit mining operations, and other heavy-duty industrial applications.

The cable’s robust construction ensures it can withstand rough handling and extreme conditions, making it ideal for powering mining equipment like mine jumbo (горный буровой станок) and mine winder (шахтный подъёмник).

Flexibility is essential in mining operations, where cables must move with heavy machinery. The flexible mining cable design allows for ease of handling and installation.

This flexibility helps to reduce strain on the cable during operation, extending its lifespan and minimizing maintenance costs.

| Feature | Benefit |

|---|---|

| British Standard BS6708 | Complies with UK mining safety standards |

| Rubber Sheathing | Protects against abrasion, mechanical stress, and oil |

| Flame-Retardant | Reduces fire risk in hazardous environments |

| Voltage Rating 0.64/1.1kV | Suitable for medium-voltage mining operations |

| 3-Core Configuration | Provides enhanced electrical performance |

| High Flexibility | Ideal for use with moving machinery |

| Oil-Resistant | Performs well in oily or greasy conditions |

The BS 6708 Type 7 Rubber Mining Cable is designed with specific standards in mind to ensure that it can handle the rigorous demands of mining applications.

Below are the technical specifications for the 3×150+70+95SQMM mining cable:

| Parameter | Specification |

|---|---|

| Standard | BS6708 Type 7 |

| Number of Cores | 3 cores |

| Conductor Size | 150mm² + 70mm² + 95mm² |

| Voltage Rating | 0.64/1.1kV |

| Sheath Material | Rubber |

| Flame-Retardant | Yes |

| Oil-Resistant | Yes |

| Operating Temperature | -25°C to +90°C |

| Bending Radius | Small, suitable for high-flex applications |

| Abrasion Resistance | High |

| Mechanical Stress Tolerance |

High |

RFQ: Common Questions and Answers

What is the composition of the BS 6708 TYPE 7 Rubber Mining Cable?

The cable consists of three main conductors with a cross-section of 150 sq mm, an additional conductor of 70 sq mm, and a protective earth conductor of 95 sq mm.

The conductors are made of high-quality stranded copper, ensuring excellent electrical conductivity and flexibility. The cable is insulated with rubber, providing durability and resistance to abrasion and chemicals.

What voltage rating does this cable support?

The 15kV mine cable (кабель шахты на 15кВ) supports a voltage rating of 0.64/1.1kV, making it suitable for various high-voltage applications in mining.

What standards does this cable comply with?

The BS 6708 TYPE 7 cable meets the British Standard BS 6708, ensuring it adheres to stringent safety and performance requirements. This standard specifies the construction, dimensions, and performance criteria for rubber-insulated cables used in mining.

Can this cable handle extreme temperatures?

Yes, the cable is designed to operate efficiently in extreme temperatures ranging from -40°C to +50°C. This makes it suitable for both underground and surface mining operations.

Is the cable flame retardant?

Yes, the cable is flame retardant and does not propagate fire when installed correctly, ensuring safety in hazardous environments.

| Cross Section | 3×16+16+16 | 3×25+16+16 | 3×35+18+16 | 3×50+25+25 | 3×70+35+35 | 3×95+50+50 | 3×120+50+70 | 3×150+70+95 | |

|---|---|---|---|---|---|---|---|---|---|

| Phase Conductor | |||||||||

| Number and cross section | mm2 | 3×16 | 3×25 | 3×35 | 3×50 | 3×70 | 3×95 | 3×120 | 3×150 |

| Stranding | mm | 126/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 360/0,50 | 475/0,50 | 608/0,50 | 740/0,50 |

| Conductor diameter | Nom. mm | 5.50 | 6.75 | 8.00 | 9.75 | 11.60 | 12.75 | 15.10 | 17.00 |

| Insulation diameter | Nom. mm | 8.85 | 10.35 | 11.60 | 13.60 | 15.70 | 17.25 | 20.05 | 22.20 |

| Screen diameter | Nom. mm | 11.15 | 12.65 | 13.90 | 15.90 | 18.00 | 19.55 | 22.35 | 24.50 |

| Earth Conductor | |||||||||

| Number and cross section | mm2 | 1×16 | 1×16 | 1×18 | 1×25 | 1×35 | 1×50 | 1×50 | 1×70 |

| Stranding | mm | 126/0,40 | 126/0,40 | 147/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 396/0,40 | 360/0,50 |

| Conductor diameter | Nom. mm | 5.50 | 5.50 | 6.00 | 6.75 | 8.00 | 9.75 | 9.75 | 11.60 |

| Pilot Conductor | |||||||||

| Number and cross section | mm2 | 1×16 | 1×16 | 1×16 | 1×25 | 1×35 | 1×50 | 1×70 | 1×95 |

| Stranding | mm | 126/0,40 | 126/0,40 | 126/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 360/0,50 | 475/0,50 |

| Conductor diameter | Nom. mm | 5.50 | 5.50 | 5.50 | 6.75 | 8.00 | 9.75 | 11.60 | 12.75 |

| Insulation diameter | Nom. mm | 10.85 | 12.35 | 13.60 | 15.60 | 17.70 | 19.25 | 22.05 | 24.20 |

| Cable details | |||||||||

| Min. overall diameter | mm | 35.8 | 39.7 | 43.1 | 48.5 | 55.1 | 62.4 | 68.0 | 70.4 |

| Max. overall diameter | mm | 38.6 | 42.9 | 46.3 | 51.8 | 58.8 | 66.1 | 72.5 | 78.4 |

| Min. bending radius | mm | 309 | 343 | 370 | 414 | 470 | 529 | 580 | 627 |

| Max. pulling tension | kgf | 480 | 642 | 834 | 1.2 | 1.68 | 2 | 2 | 2 |

| Appx. cable weight | kg/km | 2.4 | 2.95 | 3.52 | 4.6 | 6.2 | 7.9 | 9.65 | 11.5 |

| Copper weight | kg/km | 1.07 | 1.33 | 1.69 | 2.32 | 3.19 | 4.3 | 5.1 | 6.5 |

| Electrical details | |||||||||

| “Continuous current rating at 25°C Ambient” |

A | 85 | 110 | 135 | 170 | 205 | 250 | 295 | 320 |

| “Intermittent current rating at 25°C Ambient” |

A | 96 | 125 | 150 | 200 | 250 | 310 | 355 | 385 |

| Max. DC resistance at 20°C | |||||||||

| Phase Conductor | Ω /km | 1.24 | 0.795 | 0.565 | 0.393 | 0.277 | 0.21 | 0.164 | 0.132 |

| Pilot Conductor | Ω /km | 1.24 | 1.24 | 1.24 | 0.795 | 0.565 | 0.393 | 0.277 | 0.21 |

| 3 screens and earth in parallel connection | Ω /km | 0.66 | 0.56 | 0.54 | 0.44 | 0.3 | 0.26 | 0.24 | 0.176 |

| Nom. reactance at 50Hz | Ω /km | 0.109 | 0.107 | 0.101 | 0.098 | 0.095 | 0.094 | 0.092 | 0.08 |

| Nom. reactance at 60Hz | Ω /km | 0.131 | 0.128 | 0.121 | 0.118 | 0.114 | 0.113 | 0.11 | 0.096 |

| Min. insulation resistance at 20°C |

M Ω /km | 435 | 375 | 325 | 285 | 0.26 | 0.25 | 250 | 250 |

| 3 phase voltage drop on full load current | mV/A/m | 2.62 | 1.68 | 1.2 | 0.84 | 0.61 | 0.47 | 0.38 | 0.32 |

The mining trailing cable (горнопромышленный тянущий кабель) is essential for powering heavy machinery in mining environments. Its flexibility and durability make it perfect for use with equipment like mine shovels (горные экскаваторы) and drilling machines.

The underground mining cable (кабель для подземных горных работ) is specifically designed for use in underground mining operations, providing reliable power supply in challenging conditions.

Mining often takes place in harsh environments that demand tough and resilient cables.

The UK standard mining cable is designed specifically for such conditions, providing protection against abrasion, oil, and flame, all while maintaining excellent electrical performance.

| Application | Benefit |

|---|---|

| Underground Mining | Provides reliable, flame-retardant performance in confined, hazardous spaces. |

| Surface Mining | Durable in extreme weather conditions and highly resistant to mechanical stress. |

| Equipment Powering | Flexible enough for use with moving machinery, ensuring constant power. |

| Harsh Environments |

Ideal for use in demanding and hostile conditions, ensuring long-term durability. |

How does this cable perform in terms of resistance to wear and tear?

The rubber mining cable (резиновый горный кабель) is highly resistant to wear and tear, thanks to its robust rubber insulation. This ensures a long service life even in the most demanding mining applications.

What maintenance is required for this type of cable?

Regular inspection is recommended to check for any signs of damage or wear. Proper handling and storage also play a crucial role in maintaining the cable's longevity. Using mining cable hangers (держатели кабелей для горных работ) can help manage and protect the cables effectively.

Can this cable be used in Australian mining operations?

Yes, the mining cable Australia (горнопромышленный кабель Австралия) specifications are designed to meet the rigorous standards required for mining operations in Australia. This includes compliance with local safety and performance standards.

The BS 6708 TYPE 7 Rubber Mining Cable (Резиновый горный кабель BS 6708 TYPE 7) is a reliable and durable solution for various mining applications.

Its robust construction, flexibility, and compliance with British standards make it an excellent choice for ensuring a stable power supply in challenging mining environments. Whether used in underground mines or open-pit operations, this cable is built to perform under the toughest conditions.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.