Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 813

Model Number: BS 6708 TYPE 7 Medium Voltage Coal Cutter Cables

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Features: |

Oil, Sunlight, And Flame Resistant |

Flame Retardant: |

Yes |

Outer Diameter: |

0.78 Inches To 3.15 Inches |

Origin: |

China |

Certifications: |

IEC, ASTM, CSA, UL |

Jacket: |

Rubber |

Standards: |

VDE 0250 Part 813 And Part 814 |

Warranty: |

1 Year |

Armor Type: |

Steel Tape Armor |

Rated: |

0.64/1.1kV |

Material Shape: |

Braided |

Armored: |

Yes |

Standard: |

DIN VDE 0118-10 |

Color: |

Black |

Features: |

Oil, Sunlight, And Flame Resistant |

Flame Retardant: |

Yes |

Outer Diameter: |

0.78 Inches To 3.15 Inches |

Origin: |

China |

Certifications: |

IEC, ASTM, CSA, UL |

Jacket: |

Rubber |

Standards: |

VDE 0250 Part 813 And Part 814 |

Warranty: |

1 Year |

Armor Type: |

Steel Tape Armor |

Rated: |

0.64/1.1kV |

Material Shape: |

Braided |

Armored: |

Yes |

Standard: |

DIN VDE 0118-10 |

Color: |

Black |

The Feichun BS 6708 TYPE 7 Medium Voltage Coal Cutter Cables are a cutting-edge solution specifically designed to meet the rigorous demands of underground mining.

These cables offer unparalleled performance for medium-voltage power transmission in harsh and challenging environments, ensuring reliable and efficient operation for coal-cutting machinery and other mining applications.

This article dives into the cable’s features, technical specifications, and practical advantages, providing insights that will empower mining professionals to make informed decisions.

Feichun BS 6708 TYPE 7 Medium Voltage Coal Cutter Cables are engineered to cater to the following key applications:

Fixed installations for underground mining equipment.

Flexible operation for coal-cutting machinery.

Medium-voltage power transmission to motors and distribution boards.

Integration with cable chains for dynamic handling systems.

These cables are designed to provide a robust and durable power supply in environments where reliability and safety are paramount.

| Cable Type | Power Core Configuration | Pilot Core Configuration | Earth Conductor |

|---|---|---|---|

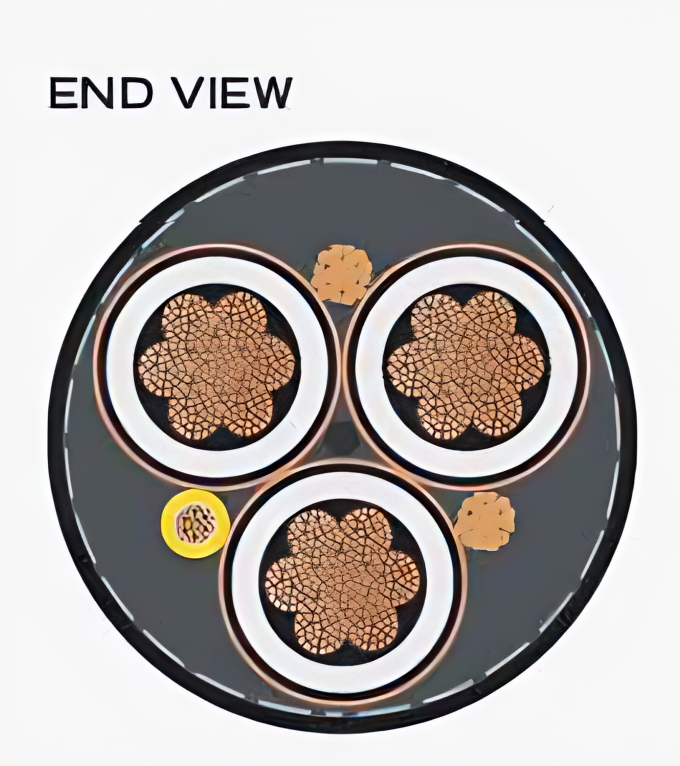

| TYPE 7 | 3 cores with metallic screens | 1 unscreened pilot core | Bare conductor |

| TYPE 7M | 3 cores with metallic screens | 1 screened pilot core | Bare conductor |

| TYPE 7S | 3 cores with metallic screens | 3 pilot cores in unscreened element | Bare conductor |

| TYPE 11 | 3 cores with metallic screens | 1 screened pilot core | Central filler |

| Parameter | Value |

| Rated Voltage [U0/U (Um)] | 0.64/1.1 kV |

| Nominal Voltage | 1100V |

| Test Voltage | 3 kV |

| Maximum Conductor Temperature | 90°C |

| Short-Circuit Conductor Temp. | 250°C |

| Installation Temperature Range: | |

| - Fixed Installation | -40°C to +80°C |

| - Flexible Operation | -25°C to +60°C |

Advanced Material Engineering

Advanced Material Engineering

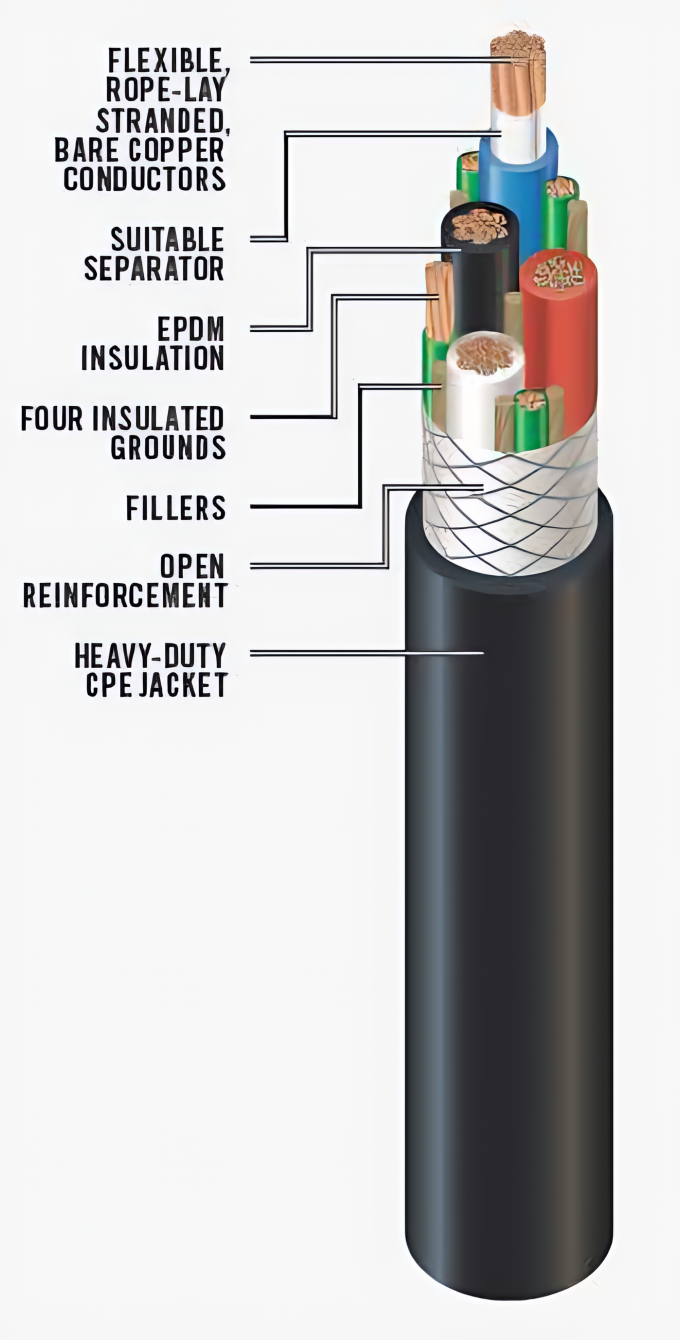

Conductor Layer

Material: Finely stranded, tinned copper (Class 5).

Benefits: Maximized conductivity and mechanical flexibility.

Insulation System

Material: EPR rubber special compound with metallic screening.

Benefits: Enhanced dielectric strength, mechanical protection, and electromagnetic shielding.

Outer Sheath

Material: Chlorinated Polyethylene (CM/CPE) with a special compound.

Benefits: Superior protection against abrasion, chemicals, and UV exposure.

| Performance Metric | Specification |

| Permanent Tensile Strength | 15 N/mm² |

| Bending Radius (Fixed Install) | 4 × Cable Diameter |

| Bending Radius (Flexible Ops) | 5 × Cable Diameter |

| Flame Retardant Compliance | EN/IEC 60332-1-2 |

| Oil Resistance | Excellent |

| Ozone Resistance | Superior |

| UV Resistance | Robust |

| Standard | Description |

| BS 6708 | British Standard for mining cables |

| BS 6360 | Copper conductor standards |

| BS 7655 | Cable insulation and sheathing materials |

| MSHA P-07-KA130007 | Mining safety compliance (United States) |

| EN/IEC 60332-1-2 | Flame retardance for industrial cables |

| DIN EN 60811-404 | Mechanical and environmental test compliance |

Feichun BS 6708 TYPE 7 Cables excel in the following environments:

Underground mining equipment

Coal-cutting machinery

Motor power supply systems

Distribution board connections

Cable chain systems for dynamic operations

Safety in extreme conditions: Flame-retardant and high-temperature-resistant materials ensure secure operations in hazardous environments.

Reliable power transmission: Minimized voltage drops and superior conductivity maintain operational efficiency.

Durability under stress: Enhanced mechanical and environmental resistance provides longer cable life, reducing maintenance downtime.

Respect the Bending Radius

Fixed Installations: Maintain a radius of at least 4 × the cable diameter.

Flexible Operations: Maintain a radius of at least 5 × the cable diameter.

Avoid Mechanical Damage

Use protective sheathing during handling and installation.

Prevent excessive pulling forces.

Cable Chain Management

Ensure proper alignment of cables in the chain.

Avoid overlapping or tangling during operation.

Conduct electrical integrity tests before installation.

Verify compatibility with site-specific conditions (temperature, chemical exposure, etc.).

Implement regular inspections to ensure operational integrity.

| Feature | Advantage |

| Multi-layer Protection | Enhanced safety and durability |

| High-Temperature Resistance | Operates reliably in extreme conditions |

| Electromagnetic Screening | Reduces interference for stable power transmission |

| Flexible Configurations | Customizable for various mining applications |

| Chlorinated Polyethylene Sheath | Robust against UV, oil, and mechanical abrasion |

The Feichun BS 6708 TYPE 7 Medium Voltage Coal Cutter Cables are a premier solution for underground mining, offering unmatched durability, safety, and performance.

These cables meet the most stringent industry standards and provide a reliable medium-voltage power supply in some of the harshest working environments.

For more details or to discuss your specific requirements, contact the Feichun Technical Solutions Team. Our experts are ready to assist with custom solutions tailored to your needs.

Note: Specifications are subject to continuous improvement. Please consult the latest technical documentation for up-to-date information.