Product Details

Place of Origin: Hefei Anhui China

Brand Name: Feichun

Certification: VDE 0250 Part 813

Model Number: PROTOMONT (VO) (N)TSKCGEWOEU

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 6,000 meters per week

Uv Resistance: |

Yes |

Weather Resistance: |

Resilient In Diverse Weather |

Insulation Material: |

EPR |

Compact Design: |

Space-efficient Construction. |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Reliable Transmission: |

Ensures Consistent Power Transmission |

Cross Sectional Area: |

95mm² |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Oil Resistant: |

Yes |

Jacket: |

Special Material |

Durable Construction: |

Long-lasting In Demanding Conditions |

Maximum Tension: |

5000 Lbs |

Uv Resistance: |

Yes |

Weather Resistance: |

Resilient In Diverse Weather |

Insulation Material: |

EPR |

Compact Design: |

Space-efficient Construction. |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Reliable Transmission: |

Ensures Consistent Power Transmission |

Cross Sectional Area: |

95mm² |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Oil Resistant: |

Yes |

Jacket: |

Special Material |

Durable Construction: |

Long-lasting In Demanding Conditions |

Maximum Tension: |

5000 Lbs |

The Feichun PROTOMONT (VO) (N)TSKCGEWOEU Coal Cutter Cables represent the pinnacle of advanced engineering, specifically designed to meet the demands of challenging underground mining environments.

These cables are engineered for seamless integration with mobile machinery, particularly coal cutting machines, offering unparalleled durability, safety, and performance.

This article delves into the product’s technical specifications, installation guidelines, and performance advantages, providing valuable insights for mining professionals.

Feichun PROTOMONT (VO) Coal Cutter Cables are specialized power supply connection cables designed for mobile equipment and machinery in underground mining operations.

The cables excel in extreme conditions, ensuring reliable performance in coal cutting machines and cable protection chains. Their advanced materials and engineering address critical challenges like tensile force absorption, abrasion, and environmental resistance.

| Attribute | Specification |

|---|---|

| Product Family | Coal Cutter Cable for Chain Operation |

| Rated Voltage [U0/U (Um)] | 1.8/3 (3.6) kV |

| Nominal Voltage | 3000V |

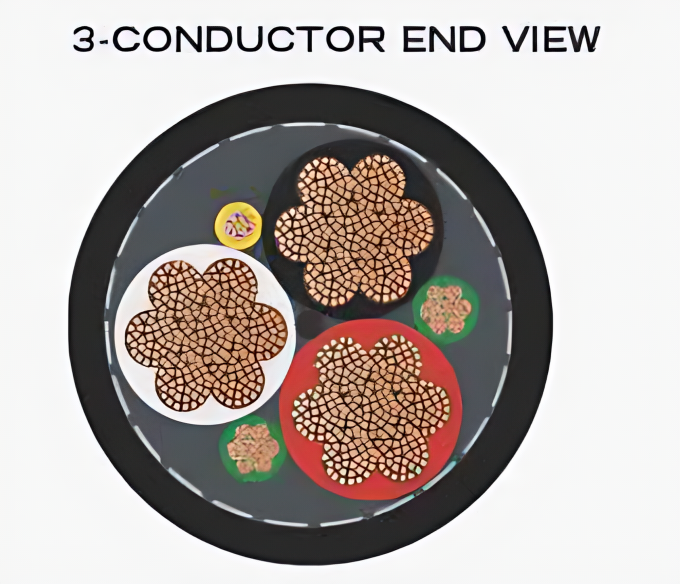

| Cable Configuration | Three main cores with double-concentric control elements |

| Attribute | Specification |

| Material | Finely stranded copper, tinned (Class FS) |

| Core Colors | Main cores: Natural color; Control cores: Blue |

| Attribute | Specification |

| Core Insulation Material | PROTOLON-Special Compound 3GI3 (EPR Rubber) |

| Outer Semi-Conductive Layer | Yes (Semi-conductive NBR easy-strip) |

| Attribute | Specification |

| Inner Sheath Material | Special EPR Compound GM1b |

| Outer Sheath Material | Chlorinated Polyethylene (CM/CPE) PROTOFIRM Compound GM5 |

| Attribute | Specification |

| Maximum Continuous Temperature | 90°C |

| Maximum Short-Circuit Temperature | 250°C |

| Installation Temperature Range (Fixed) | -40°C to +80°C |

| Installation Temperature Range (Flexible) | -20°C to +60°C |

Material: Finely stranded, tinned copper

Advantages: Maximum conductivity and excellent corrosion resistance

Material: EPR rubber with enhanced dielectric strength

Protection: Semi-conductive outer layer (NBR easy-strip) for easy installation and mechanical safety

Inner Sheath: Special EPR compound ensures high thermal stability and mechanical robustness

Outer Sheath: Chlorinated polyethylene (CM/CPE) compound provides superior oil, UV, and ozone resistance

| Attribute | Performance |

| Flame Retardancy | Compliant with EN/IEC 60332-1-2 |

| Oil Resistance | Excellent |

| Ozone Resistance | Superior |

| UV Resistance | Robust protection |

| Attribute | Performance |

| Tensile Force Absorption | Optimized for trailing behind machinery |

| Abrasion Resistance | High |

| Flexibility | Designed for cable protection chains |

| Standard | Certification Authority |

| Russian Federation | GOST-R/-K/-B Fire Certificate |

| Chinese Certification | MA China |

| International Electrical Standards | DIN VDE 0250-813, DIN EN 60228, IEC 60228 |

| Flame Retardancy Standards | DIN EN 60332-1-2, IEC 60332-1-2 |

| Mechanical & Environmental | DIN EN 60811-404, IEC 60811-404 |

Underground mining equipment

Coal cutting machines

Mobile industrial machinery

Harsh environmental conditions requiring robust power cables

Minimum Bending Radius: Adhere strictly to manufacturer guidelines to prevent damage.

Mechanical Damage Prevention: Use appropriate tools for installation to avoid physical stress on the cable.

Compatibility: Ensure the cable materials align with specific mining environment requirements.

Pre-Installation Tests: Conduct electrical integrity tests to verify performance.

Inspection Protocols: Schedule regular inspections to detect wear and tear.

Cable Routing: Plan and analyze the cable path to minimize bending and abrasion.

Fixing: Secure the cable using appropriate clamps to prevent movement.

Monitoring: Use condition monitoring systems to assess real-time cable health.

Multi-Layer Protection: Insulated layers reduce electrical hazards.

Temperature Resistance: High tolerance to extreme temperatures ensures longevity.

Mechanical Durability: Superior abrasion and tensile strength minimize breakage.

Conduct a site-specific cable routing analysis for optimized installation.

Implement a preventive maintenance schedule to identify issues early.

Utilize specialized cable management systems to extend service life.

Train personnel in proper cable handling techniques for safer operations.

Advantages for Customers

Advantages for Customers

Problem-Solving: Feichun PROTOMONT (VO) cables address critical challenges in mining operations, including tensile force absorption and resistance to environmental factors.

Material Superiority: The use of tinned copper, EPR insulation, and PROTOFIRM sheaths ensures unparalleled performance.

Compliance Assurance: Certified to meet stringent international standards, ensuring safety and reliability.

The Feichun PROTOMONT (VO) Coal Cutter Cables combine technical sophistication, superior materials, and cutting-edge engineering to deliver exceptional performance in the most challenging mining environments.

Designed to meet and exceed international standards, they are a reliable solution for underground power transmission.

For tailored consultations, application-specific guidance, or in-depth technical support, contact the Feichun Technical Solutions Team.

Stay updated with the latest technical documentation for detailed specifications.

Note: Specifications are subject to continuous improvement.