Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: Dynamic Power Cable for Moving Coal Feeder

Model Number: Dynamic Power Cable for Moving Coal Feeder

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Certifications: |

VDE, CE, RoHS |

Flexible: |

Yes |

Temperature Rating: |

-25°C To +60°C |

Bending Radius: |

10 X Cable Diameter |

Filler: |

Optional |

Feature: |

High Sound Quality |

Abrasion Resistant: |

Yes |

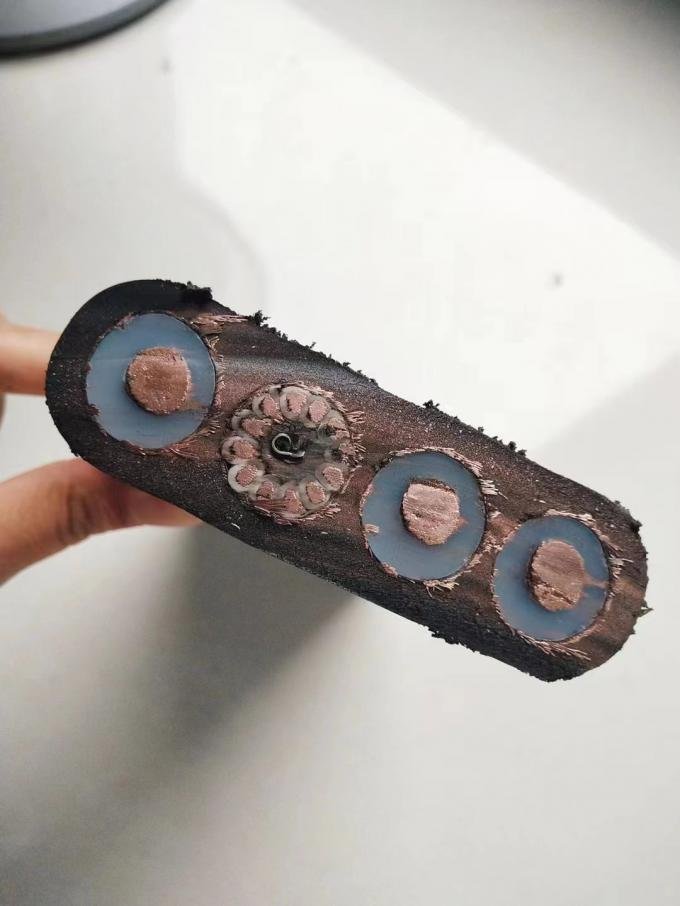

Conductor: |

Tinned Copper |

Outer Sheath Material: |

PCP (Polychloroprene) |

Shielding: |

Copper Tape |

Oil Resistant: |

Yes |

Uv Resistant: |

Yes |

Certifications: |

VDE, CE, RoHS |

Flexible: |

Yes |

Temperature Rating: |

-25°C To +60°C |

Bending Radius: |

10 X Cable Diameter |

Filler: |

Optional |

Feature: |

High Sound Quality |

Abrasion Resistant: |

Yes |

Conductor: |

Tinned Copper |

Outer Sheath Material: |

PCP (Polychloroprene) |

Shielding: |

Copper Tape |

Oil Resistant: |

Yes |

Uv Resistant: |

Yes |

When it comes to the power cables used in industrial applications, especially in harsh environments like coal feeders, reliability and durability are critical. For industries such as mining, material handling, and coal processing, having the right dynamic power cable for moving equipment can make a world of difference.

The dynamic power cable for moving coal feeders is engineered to withstand constant movement, extreme mechanical stresses, and challenging environments.

With its continuous flex rating, high strand count conductor, and tension reinforcement, this cable ensures optimal performance, extended service life, and minimal downtime in even the most demanding conditions.

In this article, we will cover the key features, installation guidelines, and real-world benefits of this specialized power cable. Whether you're overseeing the installation of a new coal feeder system or looking to upgrade your existing infrastructure, the following information will guide you through the essentials of choosing and using the dynamic power cable that best suits your needs.

A dynamic power cable is designed specifically for applications where cables are subjected to continuous movement, flexing, and tension.

These cables are frequently used in industrial environments where equipment such as moving coal feeders, conveyor belts, and hoist systems operate in motion. Unlike static cables that remain fixed in place, dynamic power cables must endure repeated flexing, twisting, and stretching, all while maintaining a steady and reliable power supply to the equipment.

For moving coal feeders, these cables must be durable enough to resist constant mechanical stress, abrasion, and the weight of the coal being moved. The high strand count conductor in this cable ensures flexibility without compromising on power transmission capabilities, making it ideal for moving and high-speed operations.

The dynamic power cable is primarily used in the following applications:

Proper installation is essential for ensuring the longevity and optimal performance of your dynamic power cable. Below are key steps and tips to follow during installation:

| Feature | Dynamic Power Cable for Coal Feeders | Standard Power Cable |

|---|---|---|

| Flexibility | High (Continuous Flex Rated) | Moderate |

| Tension Reinforced | Yes | No |

| Strand Count | High | Low to Medium |

| Chemical Resistance | Yes | Limited |

| Durability in Harsh Conditions | Excellent | Moderate |

| Operating Temperature | -40°C to 90°C | Varies |

Choosing the right power cable for your moving coal feeder is crucial for ensuring the smooth and reliable operation of your equipment. The dynamic power cable with a high strand count conductor, continuous flex rating, and tension reinforcement is engineered to meet the demanding needs of industrial applications.

By understanding the features and benefits of this specialized cable, you can make an informed decision that ensures the longevity, reliability, and safety of your equipment.

Whether you are upgrading your current system or installing a new coal feeder, this dynamic power cable is the perfect choice for high-performance and durability in challenging industrial environments.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.