Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: NSHTÖU Heavy-Duty Drum Cable

Payment & Shipping Terms

Minimum Order Quantity: 1000 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Cable Temperature Range: |

-25℃~+80℃ |

Uv Resistant: |

Yes |

Cable Type: |

Crane Festoon |

Flexibility: |

Flexible |

Voltage Rating: |

0.6/1KV |

Oil Resistant: |

Yes |

Flame Retardant: |

Yes |

Conductor Material: |

Copper |

Cable Temperature Range: |

-25℃~+80℃ |

Uv Resistant: |

Yes |

Cable Type: |

Crane Festoon |

Flexibility: |

Flexible |

Voltage Rating: |

0.6/1KV |

Oil Resistant: |

Yes |

Flame Retardant: |

Yes |

Conductor Material: |

Copper |

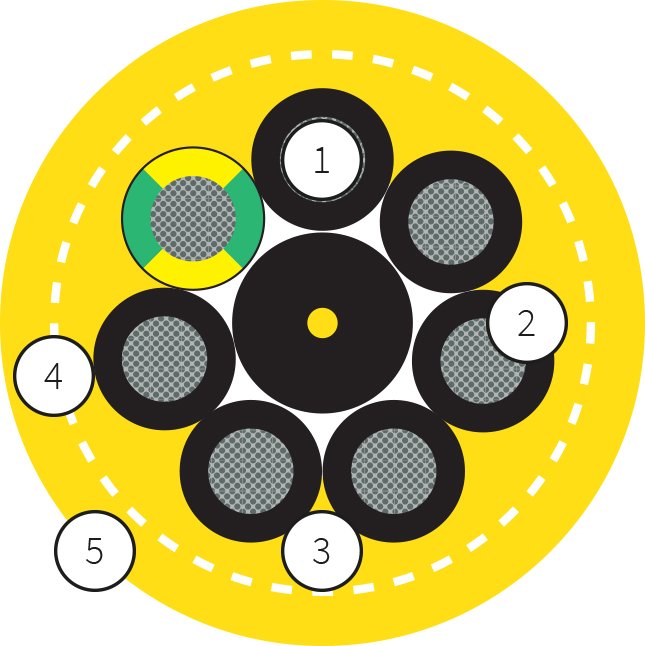

In the fast-paced world of industrial machinery, cables that can withstand constant winding, unwinding, and extreme mechanical stresses are essential. One such cable, the Heavy-Duty Drum Cable 0.6/1kV, is designed for use in applications where both tensile and torsional stresses are common.

Whether you're operating cranes, hoists, or other material handling equipment, this heavy-duty reeling cable is the solution that keeps your operations running smoothly.

With an increasing demand for flexible power cables that can endure repeated movement and harsh environmental conditions, the Heavy-Duty Drum Cable stands out for its durability, high tensile strength, and torsion resistance.

This industrial reeling cable is purpose-built for frequent winding and unwinding, making it perfect for various industrial applications where reliability is a must.

When selecting cables for industrial machinery, especially for applications involving frequent reeling and unreeling, you need to consider the mechanical stresses placed on the cable.

The Heavy-Duty Drum Cable is designed to endure high-flex, high-tensile, and torsional stresses, ensuring that your equipment operates reliably over long periods without cable failure.

Reeling cables are often exposed to high levels of tensile and torsional stress during operation. This cable has been developed to handle these stresses, preventing stretching or twisting that could damage the internal structure of the cable.

It’s designed to maintain its shape and integrity under continuous movement, making it ideal for cranes, hoists, and reeling drums.

| Feature | Specification |

|---|---|

| Tensile Strength | Up to 60 N/mm² |

| Torsional Stress Resistance | Supports up to ±150°/meter |

| Flexibility | High, suitable for frequent winding |

This combination of strength and flexibility makes it the perfect industrial reeling cable for applications that involve frequent winding and unwinding.

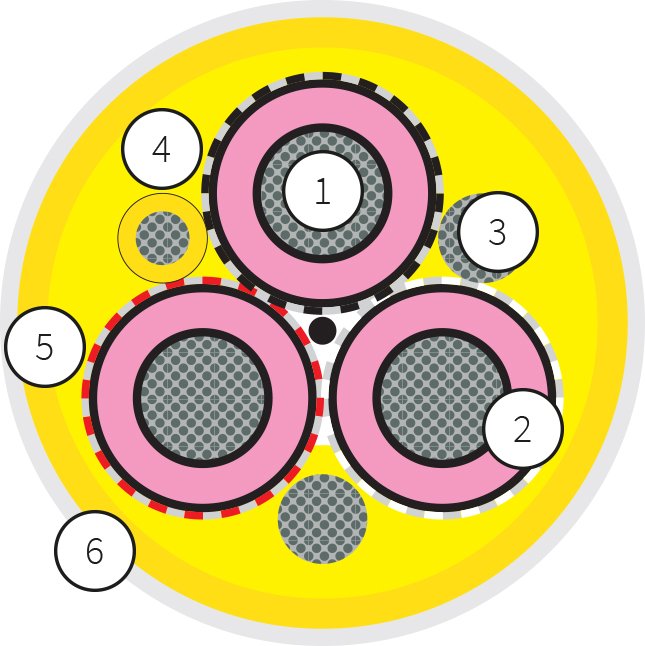

In demanding industrial environments, flexibility is key. The Heavy-Duty Drum Cable is a high-flex cable designed to perform in challenging scenarios where constant bending, twisting, and flexing are required.

Whether used in cranes, hoists, or material handling equipment, this cable maintains its flexibility without cracking or breaking.

| Application | Flexibility Rating |

|---|---|

| Cranes | High |

| Hoists | High |

| Material Handling Equipment | Very High |

The flexible power cable construction ensures that it can withstand frequent cycles of bending and flexing, ensuring a longer service life in demanding industrial applications.

Reeling cables are constantly in motion, which can cause traditional cables to wear out quickly. However, the Heavy-Duty Drum Cable is designed with high fatigue resistance, which prevents degradation even after millions of flexing cycles.

This feature is essential for industries that require reeling cable solutions to last over the long term without frequent replacement.

| Feature | Specification |

|---|---|

| Fatigue Resistance | >10 million flexing cycles |

| Operating Cycles | Designed for continuous use |

This level of durability reduces downtime and maintenance costs, making it an investment that will benefit your operation in the long run.

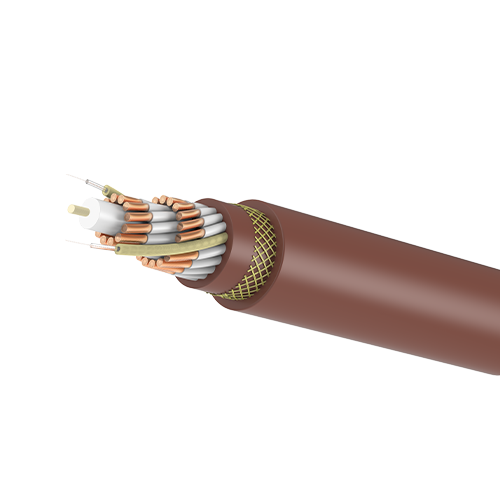

Industrial environments can be tough, with exposure to heat, oil, moisture, and extreme mechanical wear. The Heavy-Duty Drum Cable is specifically engineered to endure these conditions, making it a robust industrial cable for harsh environments.

It is built with a special sheath material that is resistant to oil, chemicals, and UV radiation, ensuring it holds up in the most challenging settings.

| Environmental Resistance | Specification |

|---|---|

| Oil Resistance | High |

| Chemical Resistance | High |

| UV Resistance | Yes |

| Temperature Range | -30°C to +90°C |

This makes it a go-to solution for industries like mining, construction, and ports where conditions can be severe and demanding.

One of the standout features of this heavy-duty drum cable is its high tensile strength, allowing it to handle the mechanical stresses of being reeled and unreeled over long distances.

This is particularly important for applications such as reeling drums and material handling equipment, where the cable must support significant weight while maintaining its electrical integrity.

| Tensile Strength | Measurement |

|---|---|

| Tensile Strength | Up to 60 N/mm² |

| Cable Elongation | Minimal under load |

With this level of strength, the cable can handle demanding loads without breaking or stretching, ensuring reliable power transmission in heavy-duty industrial settings.

The versatility of the Heavy-Duty Drum Cable makes it suitable for a wide range of industrial applications. Its ability to withstand both tensile and torsional stresses, coupled with its flexibility and fatigue resistance, means it can be used in some of the most demanding environments.

For cranes and hoists, this cable offers the durability and flexibility required for frequent lifting and lowering of heavy loads.

Its resistance to torsional stress ensures that it won’t twist or become damaged during repeated movements, making it an ideal choice for these systems.

| Application | Feature |

|---|---|

| Cranes | High tensile and torsional resistance |

| Hoists | High flexibility for frequent winding |

For reeling drums, where cables are frequently wound and unwound, this torsion-resistant cable provides a reliable solution.

It is designed to endure the repetitive motions involved in reeling applications, maintaining its structural integrity over millions of cycles.

| Feature | Specification |

|---|---|

| Reeling Cycles | >10 million |

| Torsional Stress Resistance | High, up to ±150°/meter |

This makes it a trusted solution for applications where cables are subjected to extreme mechanical stresses.

In material handling equipment, where cables are often exposed to heavy loads, high speeds, and constant movement, this industrial reeling cable offers the strength and flexibility required for smooth operation.

Its high tensile strength ensures that it can handle heavy loads without stretching or breaking.

| Application | Key Feature |

|---|---|

| Material Handling | High tensile strength |

| Lifting Systems | Fatigue-resistant for long service life |

High Tensile Strength: Capable of supporting heavy loads in industrial settings without stretching or losing its shape.

Torsional Resistance: Built to withstand torsional stress, making it suitable for frequent reeling and unreeling applications.

Flexibility: Provides high flexibility, which is essential in demanding industrial applications where cables are continuously moving.

Fatigue Resistance: Designed to endure over 10 million flexing cycles, ensuring long-term durability and reduced maintenance.

Harsh Environment Resistance: Built to withstand oil, chemicals, UV radiation, and extreme temperatures.

| Specification | Details |

|---|---|

| Voltage Rating | 0.6/1kV |

| Tensile Strength | Up to 60 N/mm² |

| Torsion Resistance | Up to ±150°/meter |

| Flexibility Class | High |

| Fatigue Resistance | >10 million flexing cycles |

| Sheath Material | Oil-resistant, UV-resistant |

| Operating Temperature Range | -30°C to +90°C |

These technical specifications highlight why this cable is the go-to solution for demanding industrial applications.

The Heavy-Duty Drum Cable 0.6/1kV is the perfect solution for industries that rely on frequent reeling and unwinding, such as those using cranes, hoists, and material handling equipment.

Its high tensile strength, torsional resistance, and flexibility make it a standout choice for applications where cables are subjected to both tensile and torsional stresses.

Invest in the heavy-duty reeling cable that will enhance the reliability of your equipment, reduce downtime, and ensure long-term operational efficiency. With its ability to endure the harshest environments and maintain performance over millions of cycles, this cable is the answer to your industrial reeling needs.

For more information on the Heavy-Duty Drum Cable and how it can benefit your specific industrial applications, contact us today!

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.