Highlight:

Drag-Lines Underground Mining Reeling Cable

, Type 455 Underground Mining Reeling Cable

Type 455 Underground Mining Reeling Cable For Drag-Lines Type 455.3 Type 455.6 Type 455.11 Type 455.22 Type 455.33

Type 455 mining cable is designed for electric cable reels with high-flexibility bending, unwinding and rewinding in mining applications.

It is a highly flexible polymer material specially used to solve high-frequency bending, with a voltage range of 3.3kV to 33kV. This makes it the best choice for excavators, towing cables and forklifts that require frequent reeling and unwinding of reeling cables with external power.

Its advantages are as follows

Highly flexible design: It can meet the high-intensity operation of mobile equipment, and frequent reeling and unreeling to meet the power supply range required by mobile machinery.

Corrosion-resistant design: Our cables are coated with compounds to meet normal use in high-oil or oily liquids.

Highest explosion-proof certification: Our mining cables are sometimes exposed to environments full of gas or other flammable gases. This environment is very common in coal mines or oil mining. We have designed a high-level safety and precision sheath to minimize safety hazards.

Designed with tensile-resistant reinforced central conductor: maximizes the overall stress and tensile resistance of the cable, avoiding electrical risks and downtime losses caused by power outages caused by possible accidents.

Applications

The Type 455 Mining Cable is suitable for a wide range of mining applications, including:

- Underground mining operations

- Surface mining operations

- Material handling equipment

- Conveyor systems

- Drilling and excavation machinery

The voltage range of the 455 mining cable is 3.3kV to 33kV.

Type 455.3 mining cable meets the power supply requirements of 3.3kV

Type 455.6 mining cable meets the power supply requirements of 6.6kV

Type 455.11 mining cable meets the power supply requirements of 11kV

Type 455.22 mining cable meets the power supply requirements of 22kV

Type 455.33 mining cable meets the power supply requirements of 33kV

Temperature range: can operate in a temperature range of minus 25°C to a maximum of 90°C.

STANDARDS:

AS/NZS 2802:2000

AS/NZS 1125

AS/NZS 3808

AS/NZS 5000.1

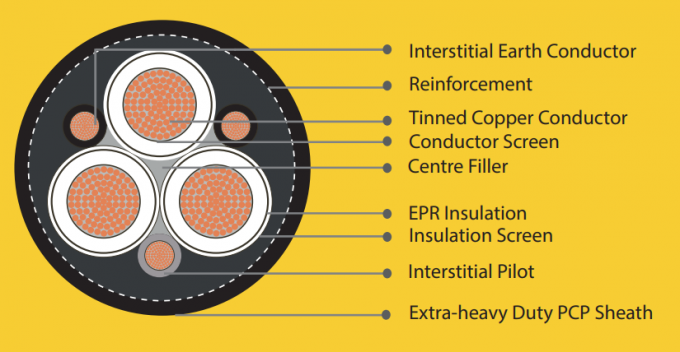

Structure: The structure is a 3+2+1 layout, including three power lines, two grounding lines and one guide line.

The guide wire mainly provides reinforcement and can be replaced with additional monitoring signal transmission optical fiber when needed to meet the needs of automated remote monitoring equipment.

Construction and Materials Insulation: Made of XR-EP-90 type EPR (ethylene propylene rubber), known for its excellent dielectric strength, flexibility, low thermal expansion and low sensitivity to water trees.

Sheath: The 455 type cable uses a heavy-duty chlorosulfonated polyethylene (HD-CSP) outer sheath, which is resistant to oils, alkalis and chemicals, which is critical for mining environments.

Conductor: Tinned annealed copper wire is used to ensure efficient conductivity and durability.

Shielding: Includes semi-conductive tape and thermosetting compounds for conductor and insulation shielding to improve cable performance and safety.

RFQ: Frequently Asked Questions and Answers

Q1: What makes Type 455 Mining Cable suitable for heavy-duty mining applications?

A1: With its EPR insulation and HD-CSP jacket construction, Type 455 Cable can withstand the mechanical stress and harsh conditions common in mining operations. Its ability to operate over a wide temperature range further enhances its suitability for heavy-duty applications.

Q2: How does Type 455 Cable ensure operational safety?

A2: Safety is ensured by providing high-quality insulation and jacket materials that are resistant to fire, oil and chemicals. Additionally, the cable complies with multiple Australian and New Zealand standards, ensuring it meets stringent safety and performance requirements.

Q3: Can this cable be customized to specific requirements?

A3: Yes, Type 455 cable can be customized to meet specific operational needs in terms of length, conductor size, and jacket material. This flexibility ensures it can be tailored to different mining applications and equipment.

Q4: What support is available for installing and using Type 455 cable?

A4: Technical support is provided to ensure the correct specification and installation of the cable. This includes guidance on meeting performance standards and ensuring the cable is compatible with a wide range of mining equipment.

Type 455 mining cable is a rugged and reliable solution designed to meet the demanding requirements of the mining industry.

Its compliance with Australian and New Zealand standards, coupled with its durable construction and flexibility, makes it an excellent choice for heavy-duty mining applications.

Whether it is an excavator, tugboat or electric shovel, this cable provides the performance and safety required for efficient mining operations.

PARAMETER

- Type 455.3 Mining Reeling Cable

- Type 455.6 Mining Reeling Cable

- Type 455.11 Mining Reeling Cable

- Type 455.22 Mining Reeling Cable

- Type 455.33 Mining Reeling Cable

| NOMINAL CONDUCTOR AREA |

STRAND SIZE |

INSULATION THICKNESS |

PILOT/EARTH CONDUCTOR |

THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| STRAND SIZE |

THICKNESS OF COVERING |

| MM² |

NO/MM |

MM |

NO/MM |

MM |

MM |

MM |

KG/100M |

| Type 455.3 Class1 |

| 16 |

126/0.40 |

2.2 |

120/0.30 |

1.4 |

4.2 |

39.4 |

224 |

| 25 |

209/0.40 |

2.2 |

120/0.30 |

1.4 |

4.5 |

43.3 |

281 |

| 35 |

285/0.40 |

2.2 |

120/0.30 |

1.4 |

4.8 |

46.7 |

336 |

| 50 |

380/0.40 |

2.4 |

183/0.30 |

1.4 |

5.3 |

51.9 |

424 |

| 70 |

203/0.67 |

2.4 |

54/0.67 |

1.4 |

5.7 |

57.0 |

556 |

| 95 |

259/0.67 |

2.4 |

70/0.67 |

1.6 |

6.1 |

60.5 |

646 |

| 120 |

336/0.67 |

2.4 |

84/0.67 |

1.6 |

6.4 |

65.6 |

786 |

| 150 |

427/0.67 |

2.4 |

112/0.67 |

1.6 |

6.5 |

69.7 |

931 |

| 185 |

518/0.67 |

2.4 |

132/0.67 |

1.6 |

6.6 |

74.5 |

1072 |

| 240 |

672/0.67 |

2.4 |

168/0.67 |

1.6 |

6.8 |

80.5 |

1310 |

| 300 |

854/0.67 |

2.4 |

228/0.67 |

1.6 |

6.9 |

86.3 |

1600 |

- Type 455.3 Mining Reeling Cable

- Type 455.6 Mining Reeling Cable

- Type 455.11 Mining Reeling Cable

- Type 455.22 Mining Reeling Cable

- Type 455.33 Mining Reeling Cable

| NOMINAL CONDUCTOR AREA |

STRAND SIZE |

INSULATION THICKNESS |

PILOT/EARTH CONDUCTOR |

THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| STRAND SIZE |

THICKNESS OF COVERING |

| MM² |

NO/MM |

MM |

NO/MM |

MM |

MM |

MM |

KG/100M |

| Type 455.6 Class1 |

| 16 |

126/0.40 |

3.0 |

120/0.30 |

1.4 |

4.7 |

43.9 |

266 |

| 25 |

209/0.40 |

3.0 |

120/0.30 |

1.6 |

5.0 |

47.8 |

332 |

| 35 |

285/0.40 |

3.0 |

120/0.30 |

1.6 |

5.3 |

51.3 |

387 |

| 50 |

380/0.40 |

3.0 |

183/0.30 |

1.6 |

5.6 |

55.1 |

466 |

| 70 |

203/0.67 |

3.0 |

54/0.67 |

1.6 |

6.0 |

60.3 |

597 |

| 95 |

259/0.67 |

3.0 |

70/0.67 |

1.8 |

6.3 |

63.5 |

692 |

| 120 |

336/0.67 |

3.0 |

84/0.67 |

1.8 |

6.5 |

68.5 |

826 |

| 150 |

427/0.67 |

3.0 |

112/0.67 |

1.8 |

6.6 |

72.6 |

977 |

| 185 |

518/0.67 |

3.0 |

132/0.67 |

1.8 |

6.7 |

77.3 |

1122 |

| 240 |

672/0.67 |

3.0 |

168/0.67 |

1.8 |

6.9 |

83.3 |

1361 |

| 300 |

854/0.67 |

3.0 |

228/0.67 |

1.8 |

7.0 |

89.1 |

1652 |

- Type 455.3 Mining Reeling Cable

- Type 455.6 Mining Reeling Cable

- Type 455.11 Mining Reeling Cable

- Type 455.22 Mining Reeling Cable

- Type 455.33 Mining Reeling Cable

| NOMINAL CONDUCTOR AREA |

STRAND SIZE |

INSULATION THICKNESS |

PILOT/EARTH CONDUCTOR |

THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| STRAND SIZE |

THICKNESS OF COVERING |

| MM² |

NO/MM |

MM |

NO/MM |

MM |

MM |

MM |

KG/100M |

| Type 455.11 Class1 |

| 16 |

126/0.40 |

5.0 |

120/0.30 |

2.0 |

5.8 |

55.1 |

392 |

| 25 |

209/0.40 |

5.0 |

120/0.30 |

2.0 |

6.1 |

59.0 |

462 |

| 35 |

285/0.40 |

5.0 |

120/0.30 |

2.0 |

6.3 |

62.2 |

527 |

| 50 |

380/0.40 |

5.0 |

183/0.30 |

2.0 |

6.4 |

65.6 |

607 |

| 70 |

203/0.67 |

5.0 |

54/0.67 |

2.0 |

6.5 |

70.2 |

742 |

| 95 |

259/0.67 |

5.0 |

70/0.67 |

2.2 |

6.7 |

73.2 |

837 |

| 120 |

336/0.67 |

5.0 |

84/0.67 |

2.2 |

6.8 |

77.9 |

982 |

| 150 |

427/0.67 |

5.0 |

112/0.67 |

2.2 |

6.9 |

82.0 |

1143 |

| 185 |

518/0.67 |

5.0 |

132/0.67 |

2.2 |

7.0 |

86.8 |

1305 |

| 240 |

672/0.67 |

5.0 |

168/0.67 |

2.2 |

7.2 |

92.8 |

1553 |

- Type 455.3 Mining Reeling Cable

- Type 455.6 Mining Reeling Cable

- Type 455.11Mining Reeling Cable

- Type 455.22 Mining Reeling Cable

- Type 455.33Mining Reeling Cable

| NOMINAL CONDUCTOR AREA |

STRAND SIZE |

INSULATION THICKNESS |

PILOT/EARTH CONDUCTOR |

THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| STRAND SIZE |

THICKNESS OF COVERING |

| MM² |

NO/MM |

MM |

NO/MM |

MM |

MM |

MM |

KG/100M |

| Type 455.22 Class1 |

| 16 |

126/0.40 |

7.6 |

120/0.30 |

2.5 |

6.6 |

68.5 |

578 |

| 25 |

209/0.40 |

7.6 |

120/0.30 |

2.5 |

6.6 |

71.7 |

653 |

| 35 |

285/0.40 |

7.6 |

120/0.30 |

2.5 |

6.7 |

74.7 |

719 |

| 50 |

380/0.40 |

7.6 |

183/0.30 |

2.5 |

6.8 |

78.2 |

810 |

| 70 |

203/0.67 |

7.6 |

54/0.67 |

2.5 |

7.0 |

82.9 |

956 |

| 95 |

259/0.67 |

7.6 |

70/0.67 |

2.5 |

7.1 |

85.7 |

1061 |

| 120 |

336/0.67 |

7.6 |

84/0.67 |

2.5 |

7.2 |

90.5 |

1221 |

| 150 |

427/0.67 |

7.6 |

112/0.67 |

2.5 |

7.3 |

94.6 |

1392 |

| 185 |

518/0.67 |

7.6 |

132/0.67 |

2.5 |

7.4 |

99.3 |

1564 |

- Type 455.3 Mining Reeling Cable

- Type 455.6 Mining Reeling Cable

- Type 455.11 Mining Reeling Cable

- Type 455.22 Mining Reeling Cable

- Type 455.33 Mining Reeling Cable

| NOMINAL CONDUCTOR AREA |

STRAND SIZE |

INSULATION THICKNESS |

PILOT/EARTH CONDUCTOR |

THICKNESS OF SHEATH |

NOMINAL OVERALL DIAMETER |

NOMINAL WEIGHT |

| STRAND SIZE |

THICKNESS OF COVERING |

| MM² |

NO/MM |

MM |

NO/MM |

MM |

MM |

MM |

KG/100M |

| Type 455.33 Class1 |

| 16 |

126/0.40 |

10.5 |

120/0.30 |

2.5 |

7.0 |

83.0 |

822 |

| 25 |

209/0.40 |

10.5 |

120/0.30 |

2.5 |

7.1 |

86.4 |

920 |

| 35 |

285/0.40 |

10.5 |

120/0.30 |

2.5 |

7.2 |

89.4 |

993 |

| 50 |

380/0.40 |

10.5 |

183/0.30 |

2.5 |

7.3 |

92.8 |

1092 |

| 70 |

203/0.67 |

10.5 |

54/0.67 |

2.5 |

7.4 |

97.4 |

1254 |

| 95 |

259/0.67 |

10.5 |

70/0.67 |

2.5 |

7.6 |

100.4 |

1372 |

| 120 |

336/0.67 |

10.5 |

84/0.67 |

2.5 |

7.7 |

105.1 |

1543 |

| 150 |

427/0.67 |

10.5 |

112/0.67 |

2.5 |

7.8 |

109.2 |

1720 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.