Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: Reeling Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

High Current Capability: |

Efficient High-current Transmission |

Underground Ready: |

Suited For Underground Mining |

Insulation: |

Special Material |

Conductor Material: |

Copper |

Temperature Resilience: |

Thrives In Extreme Temperatures |

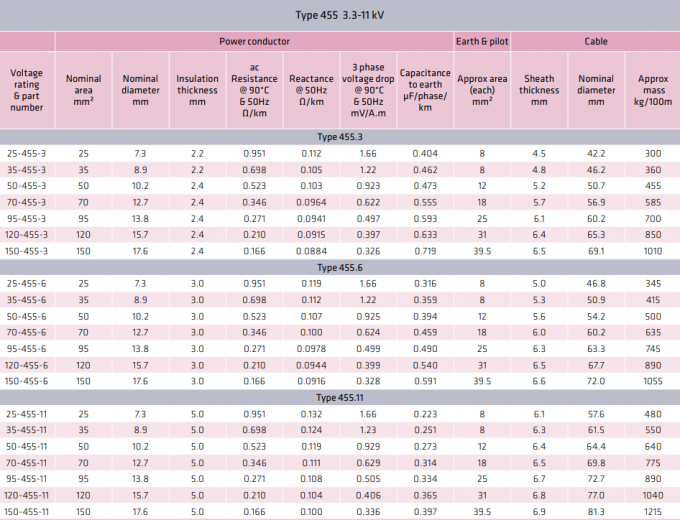

Voltage Rating: |

3.3/3.3 KV To 11/11 KV |

High Voltage Capacity: |

Voltage Resilience For Mining |

Jacket Material: |

Neoprene |

Conductor: |

Copper |

Application: |

Underground Mining |

Outer Sheath Color: |

Black |

Uv Resistant: |

Yes |

Maximum Tensile Strength: |

20kN |

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

High Current Capability: |

Efficient High-current Transmission |

Underground Ready: |

Suited For Underground Mining |

Insulation: |

Special Material |

Conductor Material: |

Copper |

Temperature Resilience: |

Thrives In Extreme Temperatures |

Voltage Rating: |

3.3/3.3 KV To 11/11 KV |

High Voltage Capacity: |

Voltage Resilience For Mining |

Jacket Material: |

Neoprene |

Conductor: |

Copper |

Application: |

Underground Mining |

Outer Sheath Color: |

Black |

Uv Resistant: |

Yes |

Maximum Tensile Strength: |

20kN |

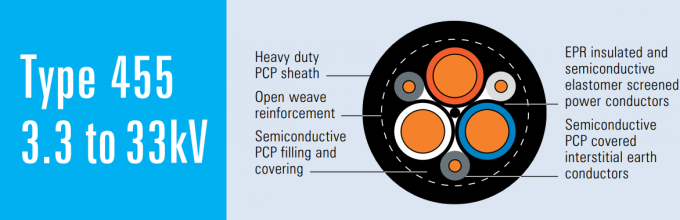

Engineered for Performance and Durability

In the demanding environments of ports and mining operations, machinery must be equipped with components that can withstand harsh conditions and intense usage.

Type 455 Reeling Cables are specifically designed to meet these challenges, offering exceptional performance and durability. Compliant with standards AS/NZS 2802:2000, AS/NZS 1125:2001, and AS/NZS 2802:2003, these cables are a top choice for both underground drum machinery and port applications.

Their high corrosion resistance makes them ideal for use in these tough environments, ensuring reliability and safety.

When it comes to selecting the right reeling cable for your operations, it’s essential to consider both the environment in which the cable will be used and the specific demands of your equipment.

Type 455 Reeling Cables are designed with these factors in mind, offering several key benefits:

Corrosion Resistance:

One of the standout features of Type 455 Reeling Cables is their exceptional resistance to corrosion. Whether they’re exposed to saltwater at a port or the harsh underground conditions in a mine, these cables are built to last.

Flexibility and Strength:

These cables are engineered to be flexible enough to handle the winding and unwinding that comes with drum machinery while maintaining the strength needed to support heavy loads and resist mechanical stress.

Compliance with Standards:

Complying with AS/NZS 2802:2000, AS/NZS 1125:2001, and AS/NZS 2802:2003 ensures that Type 455 Reeling Cables meet the high safety and performance standards required in Australia and New Zealand.

Versatility:

While these cables are particularly well-suited for underground drum machinery, they are also an excellent choice for use in docks and ports, making them a versatile solution for various industrial applications.

Corrosion is one of the biggest threats to the longevity and performance of cables in harsh environments.

In mining operations, cables are often exposed to moisture, chemicals, and other corrosive elements. At docks and ports, saltwater and varying weather conditions can quickly degrade a cable that isn’t designed to resist corrosion.

Type 455 Reeling Cables are constructed with materials that offer superior protection against these elements. This ensures that the cables maintain their integrity over time, reducing the need for frequent replacements and minimizing downtime.

For industries where every minute of operation counts, the durability of these cables translates into significant cost savings and increased productivity.

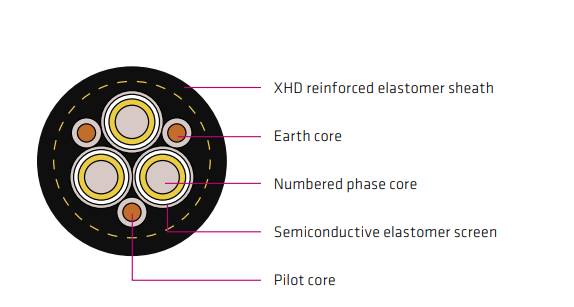

Underground mining is an environment that demands the utmost in reliability and performance from all equipment components. The reeling cables used in this setting must be capable of withstanding extreme conditions, including exposure to dust, moisture, and heavy mechanical stress.

Type 455 Reeling Cables excel in these environments, offering the flexibility needed for smooth operation and the durability required to handle the demands of underground mining.

These cables are designed to endure the constant winding and unwinding that comes with drum machinery. Their flexibility ensures that they don’t crack or break under pressure, while their strength provides the necessary support for heavy machinery.

This combination of features makes Type 455 Reeling Cables a preferred choice for underground mining operations, where reliability and safety are paramount.

In addition to their performance in underground mining, Type 455 Reeling Cables are also highly effective in port environments.

Docks and ports are tough places for cables, with constant exposure to saltwater, temperature fluctuations, and heavy machinery. These factors can quickly wear down a cable that isn’t up to the task.

Type 455 Reeling Cables offer the corrosion resistance necessary to stand up to these challenges.

Their robust construction ensures that they can handle the rough conditions of port work without degrading over time. This makes them an ideal solution for powering cranes, winches, and other heavy-duty port machinery.

Compliance with industry standards is a crucial factor when selecting cables for industrial use. Type 455 Reeling Cables meet the requirements of several important standards, including:

AS/NZS 2802:2000:

This standard specifies the requirements for flexible reeling and trailing cables for mining purposes. Type 455 Reeling Cables comply with this standard, ensuring they are safe and effective for use in mining applications.

AS/NZS 1125:2001:

This standard covers the conductors used in insulated cables, specifying their material, construction, and performance. The compliance of Type 455 Reeling Cables with this standard ensures that their conductors are reliable and capable of handling the demands of industrial use.

AS/NZS 2802:2003:

Similar to AS/NZS 2802:2000, this standard outlines the requirements for flexible reeling and trailing cables, with a focus on safety and durability. Compliance with this standard further reinforces the suitability of Type 455 Reeling Cables for demanding applications.

One of the key advantages of Type 455 Reeling Cables is their versatility. While they are excellent for specific applications like underground drum machinery and port operations, they can also be customized to meet the unique needs of other industrial environments.

Whether you need a cable that can handle extreme temperatures, resist chemical exposure, or perform in high-tension situations, Type 455 Reeling Cables can be tailored to suit your requirements.

This adaptability makes them a smart investment for any operation that requires durable, high-performance cables.

By choosing Type 455 Reeling Cables, you ensure that your machinery is equipped with a reliable power source that will keep your operations running smoothly, even in the most challenging conditions.

Safety is a top priority in both mining and port operations. Using the right cables is essential to preventing accidents and ensuring the safety of your workforce. Type 455 Reeling Cables are designed with safety in mind, complying with strict standards and offering features that reduce the risk of electrical failures and other hazards.

In addition to safety, these cables enhance operational efficiency. Their durability means less downtime for repairs or replacements, and their flexibility allows for smooth, uninterrupted operation of machinery. This combination of safety and efficiency makes Type 455 Reeling Cables an invaluable asset to any industrial operation.

When it comes to powering heavy machinery in tough environments, you need cables that can deliver consistent performance without compromising on safety or durability.

Type 455 Reeling Cables meet these demands, offering a reliable solution for both underground drum machinery and port operations. Their high corrosion resistance, flexibility, and strength make them an excellent choice for a wide range of industrial applications.

Whether you’re managing a mining operation deep underground or overseeing port activities on the waterfront, Type 455 Reeling Cables provide the reliability and performance you need to keep your machinery running smoothly. Invest in Type 455 Reeling Cables for a durable, compliant, and efficient solution that stands up to the rigors of industrial use.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.