Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Load Haul Dump (LHD) Trailing Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Safe And Reliable: |

Ensures Safety And Reliability In Diverse Operational Conditions |

Vibration Resistance: |

Resists Impact From Vibrations, Ensuring Stable Performance |

Cable Type: |

Power Cable |

Corrosion Resistance: |

Resistant To Corrosion, Ensuring Durability In Corrosive Environments |

Pressure Resilience: |

Resilient To Pressure, Suitable For Mechanical Stress |

High Flexibility: |

Offers High Flexibility, Adapting To Dynamic Equipment Movements |

Weather Resistance: |

Resistant To Various Weather Conditions, Suitable For Outdoor Use |

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

Safe And Reliable: |

Ensures Safety And Reliability In Diverse Operational Conditions |

Vibration Resistance: |

Resists Impact From Vibrations, Ensuring Stable Performance |

Cable Type: |

Power Cable |

Corrosion Resistance: |

Resistant To Corrosion, Ensuring Durability In Corrosive Environments |

Pressure Resilience: |

Resilient To Pressure, Suitable For Mechanical Stress |

High Flexibility: |

Offers High Flexibility, Adapting To Dynamic Equipment Movements |

Weather Resistance: |

Resistant To Various Weather Conditions, Suitable For Outdoor Use |

Insulation Material: |

Ethylene Propylene Rubber (EPR) |

In the challenging environment of underground mining, reliable and robust cable solutions are critical to ensuring continuous operations, equipment safety, and productivity.

The Underground Mining Load Haul Dump (LHD) Trailing Dragline MV Power Cable is specifically designed to meet the rigorous demands of underground mining equipment. This medium voltage cable (MV) ensures the efficient power supply of load-haul-dump vehicles (LHD), underground loaders, and other mining machinery in harsh environments.

This article will explore the key features, benefits, and specifications of the MV LHD trailing cable and how it can enhance the performance and safety of your mining operations.

Whether you are looking for a heavy-duty mining cable, a flexible trailing cable for mining, or a custom-made trailing cable for specific underground applications, this introduction will guide you through the essential considerations.

Underground Load Haul Dump (LHD) vehicles play a vital role in moving mined materials within tunnels. These machines, also known as underground loaders or LHD machines, operate in confined spaces where power cables must be durable, flexible, and resistant to extreme conditions.

To maintain smooth operations, the power supply is delivered via a trailing cable assembly that connects the machine to the power source.

Mining environments are notorious for their harsh conditions—abrasive surfaces, high temperatures, moisture, and exposure to chemicals. Therefore, MV LHD trailing cables need to provide:

Durability: Resistant to physical damage, including cuts, abrasions, and impacts.

Chemical Resistance: Able to withstand exposure to oils, chemicals, and lubricants.

Flexibility: Capable of supporting the constant movement of trailing cable reels without cracking or degrading.

Flame Retardance: A crucial safety feature, especially in underground operations where fire hazards can be catastrophic.

Our MV LHD trailing cables are designed to excel in these conditions, offering superior protection and performance in underground mining applications.

Abrasion and Impact Resistance

The rugged environment of underground mines is fraught with dangers that can damage cables. Our abrasion-resistant, flexible underground loader power cables are engineered with robust outer jackets to withstand physical stress. This durability reduces the risk of downtime due to cable failure.

Flame Retardant Properties

Safety is a priority in underground mining. Our flame-retardant, heavy-duty mining cables are built to prevent the spread of fire, protecting both equipment and workers. This feature complies with strict mining safety standards, ensuring that our cables perform even in high-risk environments.

Chemical and Oil Resistance

Mining equipment often operates in environments where exposure to oils, chemicals, and water is unavoidable. Our oil and chemical-resistant MV LHD trailing cables are constructed using materials that resist degradation from such exposure, increasing their longevity and ensuring consistent performance.

Flexibility for Movement

In underground mining, constant movement of machinery is inevitable. The flexible trailing cables for mining we provide are designed to bend and twist without losing their structural integrity. This flexibility ensures smooth operation and reduces the risk of cable failure due to repeated motion.

Custom-Made Solutions

Every mining site has unique requirements. We offer custom-made trailing cables tailored for specific mining equipment, ensuring compatibility with your machinery and enhancing the operational efficiency of your trailing cable system.

| Feature | Specification |

|---|---|

| Cable Type | MV Power Cable for underground mining |

| Voltage Rating | 3.3kV – 11kV |

| Conductor Material | High-conductivity copper |

| Jacket Material | Oil, chemical, and abrasion-resistant compound |

| Temperature Range | -40°C to +90°C |

| Resistance | Flame, chemical, oil, and abrasion-resistant |

| Flexibility | Designed for continuous flexing and reeling |

| Flame Retardant Standard | IEC 60332, MSHA |

| Color | Customizable, typically black and yellow |

| Customization | Available for specific machinery and site needs |

These specifications highlight the resilience and adaptability of our MV LHD trailing cables for a wide range of underground mining applications.

Cables used in underground mining must endure extreme wear and tear. Our heavy-duty mining cables are built to last in the most challenging conditions, reducing the need for frequent replacements. This translates to fewer interruptions and improved operational efficiency.

With the inclusion of flame retardant and chemical-resistant features, our cables adhere to stringent safety standards. The risk of cable-induced accidents, fires, or hazardous material exposure is significantly minimized, ensuring safer working conditions for miners and equipment operators.

Mining operations in confined spaces require cables that can navigate tight bends, twists, and turns without damage. Our flexible underground loader power cables are engineered to handle such challenges, making them ideal for use in narrow tunnels and under dynamic conditions.

Different mining sites have different requirements. Our ability to create custom-made trailing cables means that each cable can be designed for specific voltage ratings, environmental conditions, and machinery types.

This ensures maximum compatibility and performance in your unique mining environment.

Underground Tunnels and Mines

Our underground loader power cables are perfectly suited for load-haul-dump vehicles (LHD) and other mining machinery that operate in underground tunnels. The tough outer jacket and flame-retardant properties ensure durability and safety in confined spaces.

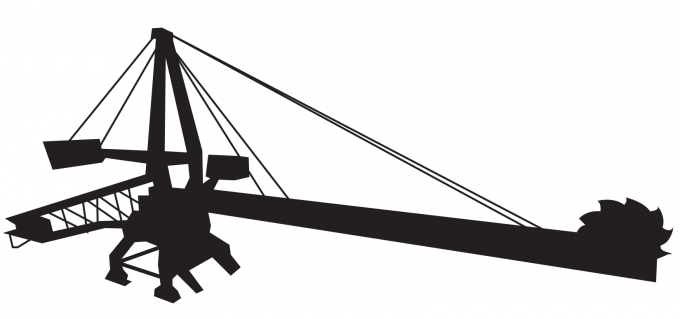

Trailing Cable Systems for Draglines

For applications involving dragline excavators or trailing cable reels, our MV LHD trailing cables provide the flexibility and strength needed to support continuous movement. This makes them ideal for large-scale excavation projects.

Heavy-Duty Mining Cable for Abrasive Environments

Mining environments expose cables to high levels of abrasion from rocks, metals, and other materials. Our abrasion-resistant, heavy-duty mining cables are designed to handle this type of wear, ensuring long service life in such settings.

Oil and Chemical Processing Sites

Mining equipment often operates in environments that involve exposure to oils and chemicals. Our chemical-resistant MV LHD trailing cables ensure that these harmful substances don’t degrade the cable over time, providing long-lasting performance.

At one underground mining site, the operators faced constant cable breakdowns due to the combination of abrasive rock surfaces and frequent exposure to hydraulic oils and chemicals.

After consulting with us, the client opted for our custom-made trailing cable, designed specifically for underground LHD machines operating in harsh conditions.

The solution provided:

A flame retardant, oil and chemical-resistant jacket, which significantly increased the cable's lifespan.

Enhanced flexibility, ensuring smooth operation even in confined spaces with heavy machine movement.

A rugged outer shell that resisted cuts, abrasions, and impacts caused by the rough terrain.

This customization resulted in reduced cable failure rates, improved safety, and significant cost savings for the mining operation.

| Cable Type | Flexibility | Abrasion Resistance | Chemical Resistance | Flame Retardance | Customization |

|---|---|---|---|---|---|

| MV LHD Trailing Cable | High | Excellent | Excellent | Yes | Yes |

| Standard Underground Mining Cable | Moderate | Good | Limited | Optional | Limited |

| High Voltage Mining Cable | Moderate | Good | Good | Yes | Yes |

| Chemical Resistant Heavy-Duty Mining Cable | Moderate | Excellent | Excellent | Optional | Yes |

This table compares the key features of different types of heavy-duty mining cables to highlight the benefits of using our MV LHD trailing cable in underground operations.

When it comes to underground mining operations, choosing the right power cable is crucial for ensuring efficiency, safety, and durability.

Our Underground Mining Load Haul Dump (LHD) Trailing Dragline MV Power Cable is designed to meet the specific challenges of mining environments, providing superior abrasion resistance, chemical resistance, flame retardant properties, and flexibility.

Whether you need a custom-made trailing cable for specific mining equipment, a heavy-duty mining cable for underground applications, or a flexible trailing cable for mining that can withstand the harshest conditions, our cables are the ideal solution.

Contact us today to learn more about our MV LHD trailing cables and how they can benefit your underground mining operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.