Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Power Shovel Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 8-10 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Conductor Size: |

4/0 AWG |

Cable Type: |

Power Cable |

Jacket Material: |

Chlorinated Polyethylene (CPE) |

Number Of Conductors: |

3 |

Max Operating Tension: |

15,000 Lbs |

Application: |

Used For Power Distribution In Dragline Operations |

Bending Radius: |

≥15D |

Standards: |

ICEA S-75-381/NEMA WC58/ASTM B-33 |

Tensile Strength: |

≥15kN |

Temperature Rating: |

90°C |

Armor Material: |

Galvanized Steel |

Voltage Rating: |

5kV |

Conductor Size: |

4/0 AWG |

Cable Type: |

Power Cable |

Jacket Material: |

Chlorinated Polyethylene (CPE) |

Number Of Conductors: |

3 |

Max Operating Tension: |

15,000 Lbs |

Application: |

Used For Power Distribution In Dragline Operations |

Bending Radius: |

≥15D |

Standards: |

ICEA S-75-381/NEMA WC58/ASTM B-33 |

Tensile Strength: |

≥15kN |

Temperature Rating: |

90°C |

Armor Material: |

Galvanized Steel |

Voltage Rating: |

5kV |

Mining is one of the toughest industries on both equipment and people. With heavy machinery operating under extreme conditions, it is crucial to use reliable, durable, and high-performance components.

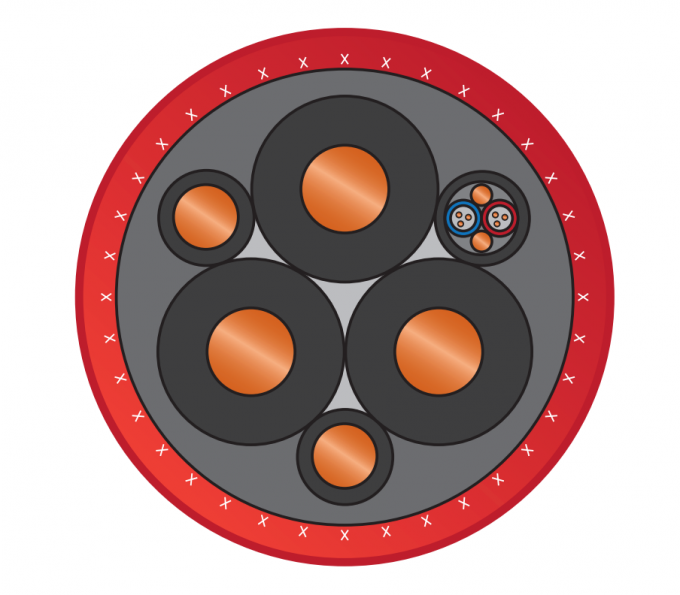

One essential component in mining operations is the abrasion-resistant, flexible electric dragline cable, which powers heavy-duty machines like electric shovels and draglines.

This product introduction will explore the features, benefits, and applications of our abrasion-resistant dragline cable specifically designed for the mining industry. These cables provide unmatched durability, flexibility, and resistance to harsh environments, making them a vital choice for mining operations.

An abrasion-resistant dragline cable is a heavy-duty, flexible power cable designed to withstand the mechanical stress, abrasion, and harsh conditions common in mining environments.

This type of cable is essential for powering electric shovels and draglines—massive machines used in surface and underground mining to move large quantities of earth and ore.

Mining cables are exposed to rugged terrains, abrasive materials, chemicals, and moisture. The abrasion-resistant flexible electric dragline cable is engineered to endure these conditions while maintaining excellent flexibility and durability.

Abrasion Resistance

The primary feature of these cables is their superior ability to resist abrasion. They are designed to handle the rough surfaces and constant friction that are inevitable in mining operations. By using specialized jacket materials, our cables maintain their integrity even when subjected to heavy wear and tear.

Flexibility

Flexibility is crucial in mining applications, where cables need to follow the movements of machines such as power shovels, draglines, and excavators. Our flexible dragline cables are designed to maintain flexibility, even in cold or high-stress environments. This flexibility helps to reduce strain on the cable, extending its lifespan and improving the overall performance of the machinery.

Heavy-Duty Construction

These cables are constructed using high-quality materials that ensure they can handle the high electrical demands of mining operations. They are designed to provide power to electric shovels and draglines, which require a reliable power source to function efficiently.

Oil and Chemical Resistance

Mining environments often expose cables to oils, chemicals, and other harmful substances. Our abrasion-resistant, oil-resistant dragline cables are designed to resist damage from these materials, ensuring long-term reliability.

Flame Retardant

Safety is a top priority in mining operations. Our flame-retardant power shovel cables meet international safety standards, providing added protection against fire hazards in both surface and underground mining applications.

| Feature | Specification |

|---|---|

| Voltage Rating | 600V to 35kV |

| Conductor Material | High-quality copper |

| Jacket Material | Abrasion-resistant, flame-retardant compound |

| Temperature Range | -40°C to +90°C |

| Oil & Chemical Resistance | Yes |

| Flame Retardant | Meets IEC and UL standards |

| Flexibility | High |

| Applications | Power shovels, draglines, excavators |

These technical specifications illustrate how our heavy-duty mining cables are built to withstand extreme environments while maintaining operational efficiency and safety.

Mining operations require cables that can withstand some of the toughest working conditions on earth. Our abrasion-resistant cables for mining are built to endure constant wear, reducing downtime and the need for frequent replacements.

This durability makes our cables a cost-effective solution for mining operations where reliability is essential.

Mining machines, such as power shovels and draglines, move constantly. Cables that supply power to these machines need to be highly flexible to avoid strain and mechanical failure. Our flexible power shovel cables are designed to maintain flexibility even under extreme pressure, ensuring seamless operation.

Mining environments vary greatly, and so do the needs of different mining companies. We offer custom-made, flexible electric excavator cables that are specifically designed to fit your unique requirements. Whether your machines operate in narrow spaces or in abrasive and chemical-heavy conditions, we provide the right cable solution tailored to your operation.

Surface Mining

In surface mining, heavy machinery like electric shovels and draglines are used to remove overburden and extract valuable minerals. These machines require reliable power cables that can withstand rough terrain, abrasive materials, and exposure to the elements. Our abrasion-resistant dragline cables are perfect for this application, providing the flexibility and durability required for continuous operation.

Underground Mining

Underground mining is even more challenging, with confined spaces, damp conditions, and exposure to chemicals. The flame-retardant power shovel cables we provide meet the safety standards for underground mining, offering both fire resistance and chemical durability. They also maintain high flexibility, essential for maneuvering in tight underground spaces.

Material Handling in Mines

In mining operations, large amounts of material are moved from one place to another using conveyors and draglines. These systems rely on heavy-duty mining cables to function efficiently. Our abrasion-resistant cables ensure that your material handling systems can operate without interruption, even in harsh environments.

| Feature | Abrasion Resistant Dragline Cable | Standard Mining Cable |

|---|---|---|

| Abrasion Resistance | Excellent | Moderate |

| Flexibility | Very High | Moderate |

| Oil & Chemical Resistance | High | Limited |

| Flame Retardant | Yes | Yes |

| Durability in Harsh Conditions | Superior | Adequate |

| Customization Options | Full | Limited |

This comparison table clearly highlights the advantages of choosing our abrasion-resistant dragline cables over standard mining cables. For operations that demand flexibility, durability, and resistance to harsh conditions, our cables provide unmatched performance.

In underground mining, cables are exposed to a variety of stresses, including bending, pulling, and exposure to chemicals and moisture. Our flexible power shovel cables offer several benefits in these tough environments:

Improved Safety:

The flame-retardant properties of our cables reduce the risk of fire in hazardous environments.

Longer Lifespan:

The combination of abrasion resistance, flexibility, and chemical resistance ensures that our cables last longer than standard cables.

Reduced Downtime:

By using cables that are resistant to wear and tear, mining operations can avoid costly downtime due to cable failures.

A major mining company in Australia needed custom-made, heavy-duty cables for their electric shovels. The operation was located in a remote area with extremely abrasive soil.

We provided them with our abrasion-resistant dragline cables tailored for their needs. The result was improved cable lifespan and reduced maintenance costs.

In South Africa, an underground mining operation required flame-retardant power shovel cables that could handle both confined spaces and harsh chemical exposure. Our team designed a custom flexible electric excavator cable that met their specifications.

The cables provided superior flexibility and safety, allowing for continuous operation without any failures.

When it comes to powering electric shovels and draglines in mining operations, choosing the right cable is crucial for ensuring reliability, safety, and efficiency. Our abrasion-resistant power shovel electrical cables are specifically engineered to meet the demands of mining environments, offering unparalleled durability, flexibility, and resistance to harsh conditions.

Whether you are operating in surface or underground mines, our heavy-duty, flexible mining cables are the perfect solution for your power needs. With a focus on abrasion resistance, flexibility, and customization, our cables ensure that your machinery runs smoothly, even in the toughest conditions.

Contact us today to learn more about our custom-made flexible electric dragline cables and how they can enhance your mining operations.

RFQ: Common Questions and Answers

Q1: Are your dragline cables available in custom lengths?

Yes, we offer custom-made, flexible dragline cables tailored to meet the specific length requirements of your mining operation.

Q2: Can these cables withstand chemical exposure in mining environments?

Absolutely. Our abrasion-resistant mining cables are also oil and chemical resistant, making them ideal for harsh industrial applications.

Q3: Do you offer flame-retardant options for underground mining?

Yes, our flame-retardant power shovel cables meet international safety standards and are designed for underground mining applications.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.