Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Dragline Power Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

High Flexibility: |

Offers High Flexibility, Adapting To Dynamic Equipment Movements |

Conductivity: |

Demonstrates Efficient Electrical Conductivity For Transmission |

Waterproof: |

Resists Water Penetration, Ideal For Moisture |

Low-Temperature Adaptability: |

Adapts Well To Low Temperatures, Suitable For Freezing Conditions |

Wear-Resistant: |

Endures Abrasion For Prolonged Durability |

High-Temperature Resilience: |

Withstands Elevated Temperatures For Optimal Performance |

High Flexibility: |

Offers High Flexibility, Adapting To Dynamic Equipment Movements |

Conductivity: |

Demonstrates Efficient Electrical Conductivity For Transmission |

Waterproof: |

Resists Water Penetration, Ideal For Moisture |

Low-Temperature Adaptability: |

Adapts Well To Low Temperatures, Suitable For Freezing Conditions |

Wear-Resistant: |

Endures Abrasion For Prolonged Durability |

High-Temperature Resilience: |

Withstands Elevated Temperatures For Optimal Performance |

In the demanding world of mining, having the right power cable for your equipment is essential. Whether you're operating a Loader, LHD (Load-Haul-Dump) machine, or dragline, having a flexible MV underground loader power cable designed for tight and confined spaces can make all the difference.

Not only does it ensure continuous operation, but it also reduces the risk of costly downtimes. This article delves into the importance of high-flexibility medium-voltage (MV) cables tailored for mining equipment in narrow underground spaces.

When it comes to underground mining, there are countless challenges. Cables need to navigate through narrow tunnels, endure mechanical stresses, and resist various environmental hazards.

That’s why a flexible MV underground loader cable specifically designed for confined spaces can significantly improve operational efficiency.

Here's why you should consider using such cables:

Flexibility in Tight Spaces:

Mines often have narrow passages that require machinery to navigate tight corners. A high-flex mining cable for narrow spaces can bend and maneuver easily without compromising performance.

Durability:

These cables are built to withstand the harsh conditions of underground loader and dragline operations. They resist abrasions, impacts, and mechanical wear, ensuring a long operational life.

Safety Standards:

In underground mining, safety is paramount. Using flame-retardant and oil and chemical-resistant cables is critical to prevent accidents.

The MV power cable designed for underground loader and dragline machinery in confined spaces has several critical features.

These are essential for both operational effectiveness and safety:

| Feature | Benefit |

|---|---|

| High Flexibility | Allows smooth operation in tight corners and confined spaces, reducing cable wear. |

| Abrasion Resistance | Withstands mechanical stress in mining environments, increasing durability. |

| Flame Retardant | Meets stringent safety standards, preventing fires from electrical faults. |

| Oil and Chemical Resistance | Ideal for underground environments where exposure to harmful substances is common. |

| Compact Design | Fits easily into narrow tunnels and tight operational spaces. |

| Medium Voltage Capability | Powers heavy-duty mining equipment without voltage drops, ensuring reliable performance. |

These cables are primarily used in underground loader (LHD) and dragline operations, but their applications span across various types of underground mining machinery. Here's where they excel:

Underground Loaders (LHD): These machines move tons of material through tight tunnels. A flexible heavy-duty cable allows smooth maneuvering without the risk of cable damage.

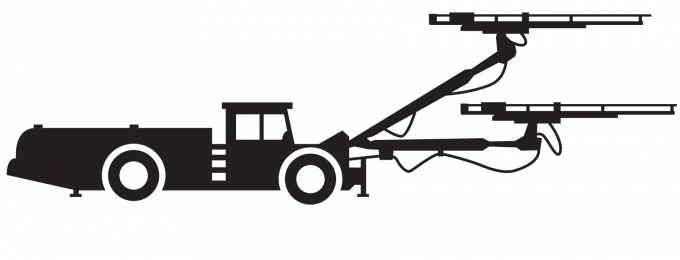

Draglines: Often used in open-cut mining, draglines operate under challenging conditions. A compact dragline power cable is essential for smooth, uninterrupted operation.

Mining Tunnels: Tight tunnels require high-flex mining cables for confined spaces. These cables provide the flexibility needed to navigate through complex underground layouts.

Specific Applications: You can even opt for custom-made flexible heavy-duty cables for specific applications, ensuring compatibility with unique machinery or mining environments.

The flexibility of these cables directly impacts the performance of mining machinery in confined spaces. A flexible MV underground loader cable allows equipment to operate at full capacity without the risk of cable wear or damage.

This translates into fewer maintenance disruptions and a more efficient workflow.

| Flexibility Level | Mining Operation Benefits |

|---|---|

| High Flexibility | Allows easy movement in confined spaces and narrow tunnels without excessive wear. |

| Moderate Flexibility | Suitable for general underground applications where space isn't as restricted. |

| Custom Flexibility | Designed for specific machinery or unique mining environments, ensuring compatibility. |

When operating in hazardous environments, safety is non-negotiable. Cables must comply with international safety standards to ensure safe operation.

Flame-retardant cables, for example, are essential in underground environments to prevent potential fire hazards from electrical malfunctions.

Key safety standards for MV underground loader cables include:

IEC 60502-2: This standard governs the design and testing of medium-voltage power cables, ensuring they are suitable for underground use.

MSHA (Mine Safety and Health Administration): MSHA-approved cables meet the highest safety requirements for underground mining in the U.S.

AS/NZS 1802: Specific to Australia and New Zealand, this standard ensures cables are suitable for mining equipment in confined spaces, making it crucial for flexible heavy-duty cables in tight tunnels.

Another major benefit of these cables is their resilience to harsh environmental conditions. Underground mining environments can expose cables to chemicals, oils, and other hazardous substances.

That’s where oil and chemical-resistant, flexible MV underground loader cables come in. These cables are designed to endure exposure to harmful substances, ensuring consistent performance.

| Environmental Challenge | Cable Solution |

|---|---|

| Oil Exposure | Oil-resistant cables prevent deterioration from constant exposure to lubricants. |

| Chemical Exposure | Chemical-resistant cables ensure durability in environments with harsh substances. |

| Abrasive Surfaces | Abrasion-resistant cables offer protection from rough mining surfaces. |

| Fire Hazards | Flame-retardant cables mitigate the risk of fire, especially in closed spaces. |

No two mining operations are the same. That’s why many manufacturers offer custom-made flexible heavy-duty cables.

These cables can be designed to meet the specific needs of your operation, whether it's unique voltage requirements, environmental conditions, or machinery configurations.

Some customization options include:

Cable Length: Depending on the layout of your mine, you may need cables of varying lengths. Customizing your cable ensures the right fit for your application.

Insulation Material: Choose from different insulation materials to suit your environment. For example, chemical-resistant insulation is ideal for environments with high chemical exposure.

Voltage Ratings: Depending on the power requirements of your mining equipment, you can customize the voltage rating of your cables.

The flexible MV underground loader LHD dragline power cable is an essential component of any underground mining operation. Its flexibility, durability, and resistance to harsh environmental factors make it the perfect solution for confined spaces and demanding applications.

Investing in high-flex mining cables can drastically improve your operation’s efficiency, reduce maintenance costs, and enhance overall safety. Whether you're looking for a compact dragline power cable for narrow tunnels or a custom-made heavy-duty cable for specific applications, the right power cable can make all the difference in your mining operations.

If you're looking to upgrade your mining cables or need a custom solution, consider contacting a manufacturer that specializes in mining cables for narrow spaces. By opting for a high-quality, custom-made flexible cable, you'll be ensuring smooth and safe operations for years to come.

Q: What is the voltage rating of these cables?

A: These cables typically have a medium voltage (MV) rating, perfect for underground loaders and draglines.

Q: Can these cables withstand harsh chemicals?

A: Yes, these cables are designed with oil and chemical-resistant insulation, making them ideal for challenging underground environments.

Q: Do you offer custom cable lengths?

A: Yes, we can customize the length of the cable to suit your specific requirements.

Q: Are these cables flame-retardant?

A: Absolutely. These cables meet stringent flame-retardant standards to ensure safety in underground environments.

Q: Can I use these cables in tight mining tunnels?

A: Yes, these cables are designed specifically for narrow spaces and confined areas, making them perfect for underground tunnels.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.