Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CE、ISO

Model Number: Festoon Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

High Temperature Stability: |

Operates Within A Wide Temperature Range, Suitable For Industrial Environments With Elevated Temperatures, Guaranteeing Consistent Performance |

Oil Resistance: |

Features A Design Specifically Resistant To Industrial Oils, Guaranteeing Sustained Performance In Environments With Common Oil Contaminants |

Conductor Material: |

Copper |

Compliance With Standards: |

Adheres To Relevant Industry Standards And Certifications, Ensuring The Cable's Compliance With Safety And Performance Regulations |

High Flexibility: |

Engineered With Advanced Elastomeric Compounds, Ensuring Exceptional Flexibility For Seamless And Precise Movements In Complex Crane And Lifting Systems |

Weather Resistance: |

Designed To Withstand Outdoor Conditions, UV-resistant Materials Shield The Cable From Sunlight Exposure, Ensuring Prolonged And Reliable Operation. |

High Temperature Stability: |

Operates Within A Wide Temperature Range, Suitable For Industrial Environments With Elevated Temperatures, Guaranteeing Consistent Performance |

Oil Resistance: |

Features A Design Specifically Resistant To Industrial Oils, Guaranteeing Sustained Performance In Environments With Common Oil Contaminants |

Conductor Material: |

Copper |

Compliance With Standards: |

Adheres To Relevant Industry Standards And Certifications, Ensuring The Cable's Compliance With Safety And Performance Regulations |

High Flexibility: |

Engineered With Advanced Elastomeric Compounds, Ensuring Exceptional Flexibility For Seamless And Precise Movements In Complex Crane And Lifting Systems |

Weather Resistance: |

Designed To Withstand Outdoor Conditions, UV-resistant Materials Shield The Cable From Sunlight Exposure, Ensuring Prolonged And Reliable Operation. |

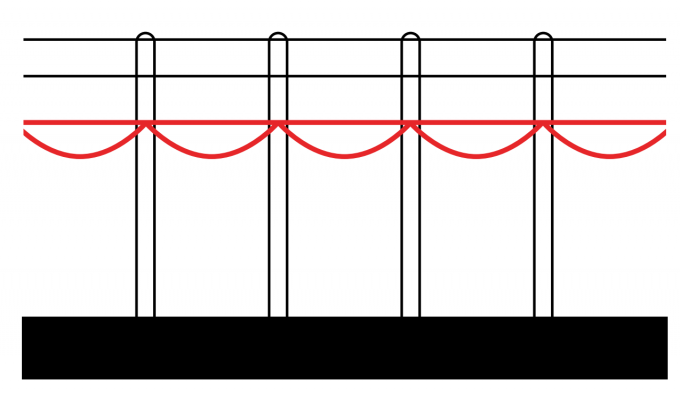

In today’s fast-paced industrial world, equipment that operates in harsh and demanding environments needs to be both reliable and resilient. One such essential component in industrial operations is the Chemical Resistance Crane Festoon Cable, particularly for applications that involve exposure to chemicals and corrosive elements.

Our black and yellow custom festoon cables are designed to withstand such environments, ensuring uninterrupted operation, safety, and durability.

This article delves into the features, benefits, and specifications of our chemical-resistant festoon cables.

Whether you're operating cranes, material handling systems, or other industrial machinery in harsh conditions, you can rely on our custom festoon cable solutions for unmatched performance.

A chemical-resistant festoon cable is specifically engineered to resist deterioration caused by exposure to various chemicals, oils, and other corrosive substances. These cables are commonly used in environments where standard cables would degrade rapidly.

Our black and yellow festoon cables not only offer excellent protection against chemicals but also provide high visibility, making them ideal for hazardous work zones.

Key applications include:

Crane cable systems in chemical plants.

Material handling systems in corrosive environments.

Outdoor festoon cables exposed to the elements and chemical agents.

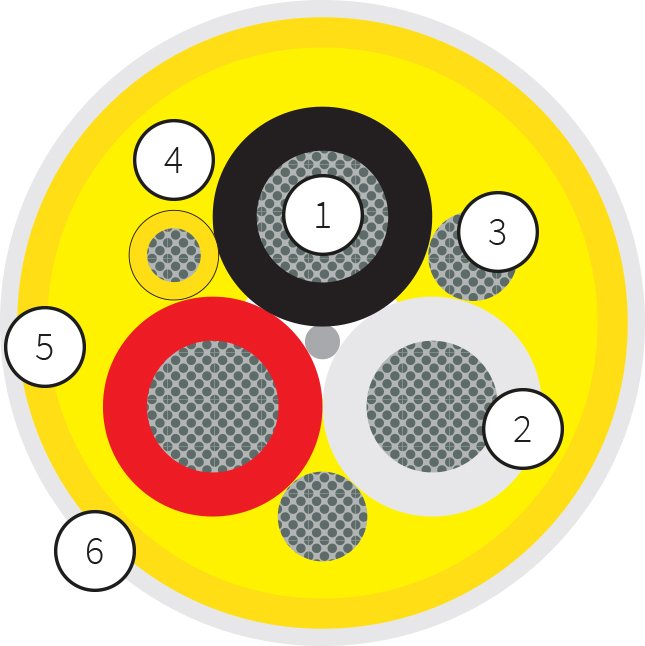

Our chemical-resistant festoon cables for harsh environments are designed with durability and flexibility in mind.

These cables provide robust performance in settings that expose them to aggressive chemicals, oils, and moisture, without compromising on flexibility or ease of use.

Key features include:

Chemical Resistance: Engineered with special compounds that prevent degradation from chemicals, our cables are perfect for environments like chemical plants, refineries, and manufacturing units where exposure to corrosive materials is common.

Flexibility: These flexible festoon cables maintain high flexibility even under constant movement, ensuring that your machinery operates smoothly without interruptions.

High Durability: Our heavy-duty festoon cables for corrosive applications are built to last, reducing the need for frequent replacements and downtime.

Customization: We offer custom festoon cables to meet specific chemical compatibility requirements, tailored to your industrial setup.

| Feature | Specification |

|---|---|

| Cable Type | Festoon Cable |

| Conductor Material | High-quality copper |

| Jacket Material | Chemical-resistant compounds |

| Operating Voltage | 300V to 600V |

| Temperature Range | -40°C to 90°C |

| Resistance | Oil, chemical, UV, and water resistance |

| Color | Black and Yellow |

| Flexibility | Highly flexible for continuous movement |

These specifications reflect the durability and adaptability of our industrial festoon cables in chemical-heavy environments.

When operating in chemical plants, refineries, or other industrial sectors where cables are exposed to harmful chemicals, it’s essential to have a cable that can withstand these conditions. Our chemical-resistant festoon cables are designed specifically for such environments, ensuring they won’t deteriorate or fail prematurely.

Industries like manufacturing and processing require heavy-duty festoon cables that can endure constant wear and tear, while still performing at high levels. Our cables are engineered for corrosive applications, offering the strength and resilience needed to perform in demanding environments.

Not all industries face the same challenges, which is why we provide custom festoon cables tailored to your exact requirements. Whether you need a cable resistant to specific chemicals or designed for unique operating conditions, we can create the right solution for your operations.

Chemical Processing Plants:

One of the most common applications for our industrial festoon cables is in chemical processing facilities. These environments often contain a range of corrosive chemicals, and regular exposure can degrade standard cables quickly. Our chemical-resistant festoon cables are built to withstand this harsh exposure.

Outdoor Applications:

Outdoor machinery exposed to both environmental elements and industrial chemicals requires a durable cable solution. Our chemical-resistant cables for outdoor use are resistant to UV radiation, water, and chemical exposure, making them ideal for cranes and other outdoor equipment.

Material Handling in Chemical Plants:

For systems involved in moving or processing materials in chemical plants, such as cranes and hoists, the risk of cable damage is high due to constant movement and exposure to chemicals.

Our black and yellow festoon cables for material handling are designed to ensure safety and visibility while maintaining resistance to chemical degradation.

| Feature | Chemical-Resistant Festoon Cable | Standard Festoon Cable |

|---|---|---|

| Chemical Resistance | Excellent | Limited |

| Durability in Harsh Environments | High | Moderate |

| Flexibility | Very High | Moderate |

| Customization Options | Full | Limited |

| Color | Black & Yellow | Varies |

| Corrosion Resistance | Excellent | Low |

| Visibility in Hazardous Areas | High | Moderate |

This table highlights the key advantages of using our chemical-resistant festoon cables compared to standard cables, emphasizing their superior resistance to chemicals and harsh environments.

One of the standout features of our cable range is the ability to customize festoon cables for specific chemical exposures. This is particularly important in industries where unique chemical environments require more specialized solutions.

For example, a facility that handles sulfuric acid may need a cable with different material properties compared to a plant dealing with petroleum-based chemicals.

We work with our clients to determine the best materials and configurations for their specific needs, ensuring that their custom festoon cable offers optimal performance and safety.

Color plays a vital role in industrial safety. Our black and yellow festoon cables offer high visibility, which is crucial in ensuring that workers can easily identify cable locations in busy and potentially hazardous environments. This not only improves safety but also enhances operational efficiency.

The black and yellow design of our festoon cables ensures that they are clearly visible, even in dimly lit areas, reducing the risk of accidental damage or mishandling.

In conclusion, when it comes to selecting the right cable for industrial operations, particularly in chemical-laden environments, it’s important to choose a solution that offers both durability and reliability. Our chemical-resistant festoon cables are specially designed to perform in some of the harshest conditions, providing long-lasting durability, flexibility, and resistance to corrosive elements.

Whether you need a flexible festoon cable with chemical resistance for your material handling systems, a heavy-duty festoon cable for corrosive applications, or a custom festoon cable for specific chemical compatibility, we are your go-to industrial festoon cable supplier. Our cables are built to last and can be tailored to meet the specific needs of your operation.

Contact us today to discuss your specific cable requirements, and let us help you find the perfect solution for your industrial needs.

RFQ: Common Questions and Answers

Q1: Can I customize the color of the festoon cable?

Yes, we offer custom options, including the highly visible black and yellow festoon cable.

Q2: What chemicals can your festoon cables resist?

Our chemical-resistant festoon cables are designed to resist a variety of industrial chemicals. Specific resistance depends on the cable’s jacket material, which can be customized for specific chemical environments.

Q3: Are these cables suitable for outdoor use?

Absolutely. Our chemical-resistant cables are perfect for both indoor and outdoor use, with added resistance to UV, water, and harsh chemicals.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.