Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: NTSWOEU

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Robust Durality: |

Heavy-duty Construction |

Easy Termination: |

Simplifies The Termination Process |

Flexibility: |

Highly Flexible |

Armor Material: |

Galvanized Steel |

Oil Resistant: |

Yes |

Dynamic Adaptability: |

Flexible In Dynamic Settings |

Shielding Coverage: |

100% |

Cable Temperature: |

105℃ |

Sheath Color: |

Black |

Tensile Strength: |

2000 Lbs |

Mining Conveyor System: |

Integral For Conveying |

Stacker And Reclaimer: |

Integral For Both Functions |

Bending Radius: |

10 X Cable Diameter |

Material: |

Steel |

Robust Durality: |

Heavy-duty Construction |

Easy Termination: |

Simplifies The Termination Process |

Flexibility: |

Highly Flexible |

Armor Material: |

Galvanized Steel |

Oil Resistant: |

Yes |

Dynamic Adaptability: |

Flexible In Dynamic Settings |

Shielding Coverage: |

100% |

Cable Temperature: |

105℃ |

Sheath Color: |

Black |

Tensile Strength: |

2000 Lbs |

Mining Conveyor System: |

Integral For Conveying |

Stacker And Reclaimer: |

Integral For Both Functions |

Bending Radius: |

10 X Cable Diameter |

Material: |

Steel |

Feichun’s NTSWOEU High-Flex Winding Solutions represent a significant leap in cable technology, designed specifically for the rigorous demands of material handling equipment across various industries.

With a focus on extreme flexibility, durability, and environmental resistance, the NTSWOEU cable technology ensures optimal performance in both challenging indoor and outdoor environments.

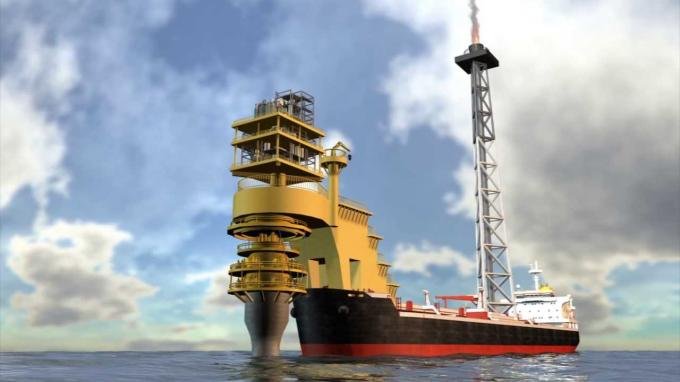

This innovative cable solution is tailored to meet the needs of industries such as warehouse automation, port logistics, and manufacturing lines, providing a reliable and cost-efficient alternative to traditional cables.

In today’s material handling environments, the performance of cables directly impacts the reliability and efficiency of equipment. Equipment such as cranes, automated guided vehicles (AGVs), and robotic material handling systems require cables that can withstand the stress of continuous movement, high-flex cycles, and extreme conditions.

Feichun’s NTSWOEU High-Flex Winding Solutions address these challenges, offering an innovative approach to cable design that ensures longer service life, lower maintenance costs, and enhanced operational efficiency.

The NTSWOEU cable is engineered for high-flexibility and extreme durability, capable of performing in demanding applications that require both mechanical resilience and electrical integrity.

NTSWOEU Cable Breakdown:

This unique combination of materials and design features ensures that the NTSWOEU High-Flex Winding Solutions outperform traditional cables, providing exceptional mechanical strength, flexibility, and electrical performance.

The NTSWOEU High-Flex Winding Solution is specifically designed to endure extreme bending, twisting, and flexing cycles, which are common in material handling equipment.

The cable’s electrical performance is optimized for high-efficiency energy transfer and minimal signal degradation.

In industrial environments, cables face extreme temperatures, chemicals, and weather conditions. The NTSWOEU High-Flex Winding Solution is engineered to withstand these challenges.

Modern material handling equipment faces specific cable requirements to keep operations running smoothly. From high-frequency movement to environmental exposure, cables must offer high flexibility and mechanical strength.

The NTSWOEU High-Flex Winding Solutions are engineered for a variety of industry applications, each demanding specific cable performance features.

The NTSWOEU High-Flex Winding Solutions outperform traditional cables in several key areas:

| Feature | Traditional Cable | NTSWOEU High-Flex Cable |

|---|---|---|

| Cycle Life | 1-2 million cycles | 10 million cycles |

| Flexibility | Limited | Extreme flexibility |

| Maintenance | High costs due to wear | Reduced maintenance costs |

| Abrasion Resistance | Standard | Superior resistance |

| Electrical Integrity | Susceptible to degradation | High insulation resistance |

Proper installation techniques are crucial to maximize the cable’s lifespan and performance.

The NTSWOEU High-Flex Winding Solution minimizes environmental impact by:

The NTSWOEU cable offers a favorable TCO when compared to traditional cables due to:

Feichun’s NTSWOEU High-Flex Winding Solutions adhere to rigorous international standards, ensuring global compatibility and safety:

Feichun implements strict quality control at every stage of production:

Feichun continues to invest in research and development to push the boundaries of cable technology:

As industries evolve, so do cable needs. Feichun’s innovative technology opens doors to new applications in:

Feichun’s NTSWOEU High-Flex Winding Solutions provide a powerful tool for industries requiring flexible, durable, and reliable cables in their material handling systems.

By delivering superior performance in extreme conditions, these cables represent the future of high-performance industrial cables, meeting both economic and environmental needs.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.