Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: NTSCGERLWOEU

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-60 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Standards: |

UL Listed, CSA Certified |

Impact Resistant: |

Guards Against Impact Damage |

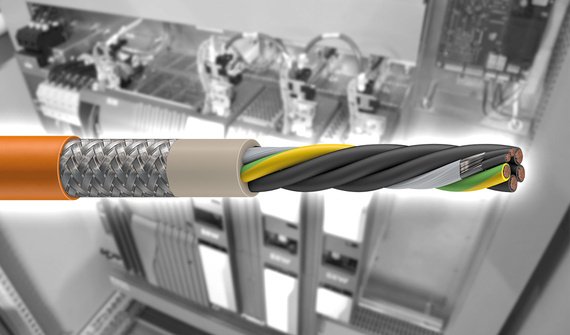

Cable Structure: |

Multi-strand |

Industrial Reclaimer: |

Ideal For Reclaiming Processes |

Dynamic Adaptability: |

Flexible In Dynamic Settings |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Stacker And Reclaimer: |

Integral For Both Functions |

Temperature Rating: |

-5°C To +70°C |

Armor Type: |

Galvanized Steel |

Core Identification: |

Color-coded |

Max Tension: |

600 Lbs |

Shielding: |

Braided Copper Wire |

Flexible: |

Yes |

Certifications: |

UL Listed, CSA Certified |

Standards: |

UL Listed, CSA Certified |

Impact Resistant: |

Guards Against Impact Damage |

Cable Structure: |

Multi-strand |

Industrial Reclaimer: |

Ideal For Reclaiming Processes |

Dynamic Adaptability: |

Flexible In Dynamic Settings |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Stacker And Reclaimer: |

Integral For Both Functions |

Temperature Rating: |

-5°C To +70°C |

Armor Type: |

Galvanized Steel |

Core Identification: |

Color-coded |

Max Tension: |

600 Lbs |

Shielding: |

Braided Copper Wire |

Flexible: |

Yes |

Certifications: |

UL Listed, CSA Certified |

In industries like mining, construction, and logistics, maintaining connectivity and ensuring reliable power transmission under extreme conditions is crucial.

The NTSCGERLWOEU cable series represents a groundbreaking solution for such challenges. With advanced materials and innovative designs, these cables are tailored for large-scale material handling equipment, offering unmatched durability, efficiency, and adaptability in global industrial operations.

This article dives deep into the technology behind NTSCGERLWOEU cables, their applications in extreme environments, and the benefits they provide. Whether you’re facing harsh weather, mechanical stresses, or demanding operational needs, these cables are engineered to excel.

Industries operating in extreme conditions face numerous challenges:

Large-scale material handling equipment, such as cranes, stackers, and conveyors, depends on robust electrical systems. The role of cables in this ecosystem is critical, as failures can lead to costly downtime and safety risks.

The NTSCGERLWOEU series has been developed to address these challenges, delivering superior performance and longevity in demanding environments.

From traditional PVC-insulated cables to today’s multi-layered composite solutions, cable technology has undergone significant evolution. NTSCGERLWOEU cables embody this transformation, featuring:

These advancements reflect the growing complexity of industrial operations and the need for connectivity solutions that can withstand the harshest conditions.

The NTSCGERLWOEU series boasts cutting-edge materials and precise engineering:

| Component | Specification |

|---|---|

| Conductor | High-purity copper for maximum electrical conductivity |

| Insulation | Cross-linked polyethylene (XLPE) for thermal resistance and low dielectric loss |

| Sheath Material | Chlorinated polyethylene (CPE) for chemical resistance and flexibility |

| Armour Layer | Galvanized steel for mechanical protection |

| Operating Temperature | -40°C to +90°C |

| Voltage Rating | Up to 15kV |

Extreme Environmental Resistance

With materials like CPE, these cables are resistant to abrasion, moisture, and chemical exposure.

Electrical Transmission Efficiency

High-purity copper conductors ensure minimal energy loss even over long distances.

Mechanical Stress Tolerance

Reinforced structures withstand repetitive bending and mechanical impacts.

Durability in Harsh Conditions

Tested to operate reliably under extreme temperatures and high humidity.

NTSCGERLWOEU cables are tailored for various applications:

| Industry | Example Applications |

|---|---|

| Mining | Conveyor systems, drilling rigs |

| Construction | Tower cranes, concrete mixers |

| Logistics | Automated storage and retrieval systems |

| Manufacturing | Robotic arms, assembly line equipment |

| Extreme Environments | Arctic operations, offshore platforms |

Designed to meet international safety standards, these cables perform reliably across:

| Performance Metric | Traditional Cables | NTSCGERLWOEU Cables |

|---|---|---|

| Electrical Efficiency | Moderate | High |

| Resistance to Environmental Stress | Low | Superior |

| Lifespan | 5-7 years | 10-15 years |

| Maintenance Frequency | High | Low |

The NTSCGERLWOEU cables outshine traditional options by offering higher reliability, lower maintenance costs, and a longer lifespan.

| Methodology | Benefit |

|---|---|

| Predictive Maintenance | Identifies issues before failures occur. |

| Diagnostic Systems | Monitors performance in real-time. |

| Performance Monitoring | Ensures optimal operation under varying loads. |

Feichun Cable continues to invest heavily in R&D, focusing on:

The NTSCGERLWOEU series sets a new benchmark in extreme-duty cable solutions, combining advanced engineering with real-world practicality. These cables empower industries to overcome the most demanding challenges, ensuring safety, reliability, and efficiency.

Explore how NTSCGERLWOEU cables can transform your material handling operations. Contact Feichun Cable for a consultation and technical documentation tailored to your needs.

| Specification | Details |

|---|---|

| Voltage Range | 1kV to 15kV |

| Temperature Range | -40°C to +90°C |

| Conductor Material | High-purity copper |

| Compliance | IEC 60502, ISO 9001, ISO 14001 |

For additional details or technical inquiries, reach out to our global support network.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.