Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: 2YSLGCGOEU

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 16,000 meters per week

Impact Resistant: |

Guards Against Impact Damage |

Shielding Material: |

Tinned Copper |

Efficient Stockpiling: |

Optimizes Material Storage |

Heavy Equipment Wiring: |

Designed For Robust Machinery |

Minimum Bending Radius: |

5 X Cable Diameter |

Mining Stockpile Cables: |

Essential For Stockpiling |

Tensile Strength: |

1000 Lbs |

Material: |

Steel |

Max Tension: |

600 Lbs |

Low Smoke Emission: |

Emits Minimal Smoke |

Bulk Handling System: |

Streamlines Material Handling |

Conductor Size: |

2.5mm² To 240mm² |

Bending Radius: |

6 X Cable Diameter |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Impact Resistant: |

Guards Against Impact Damage |

Shielding Material: |

Tinned Copper |

Efficient Stockpiling: |

Optimizes Material Storage |

Heavy Equipment Wiring: |

Designed For Robust Machinery |

Minimum Bending Radius: |

5 X Cable Diameter |

Mining Stockpile Cables: |

Essential For Stockpiling |

Tensile Strength: |

1000 Lbs |

Material: |

Steel |

Max Tension: |

600 Lbs |

Low Smoke Emission: |

Emits Minimal Smoke |

Bulk Handling System: |

Streamlines Material Handling |

Conductor Size: |

2.5mm² To 240mm² |

Bending Radius: |

6 X Cable Diameter |

Tailored For Handling: |

Enhances Material Handling Efficiency |

The 2YSLGCGOEU winding cable stands as a groundbreaking solution for powering heavy-duty industrial transportation equipment.

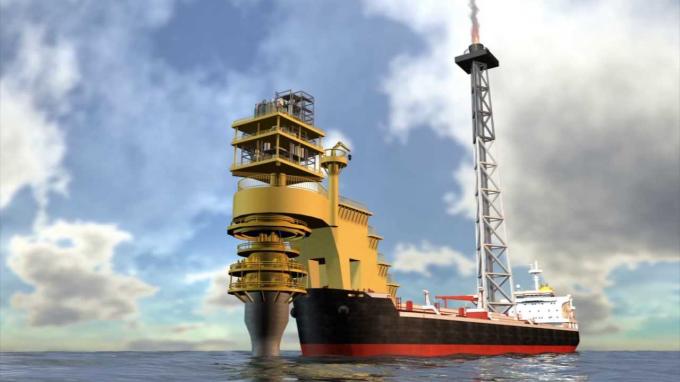

Designed to excel in demanding environments such as mining, ports, and construction sites, this cable combines durability, flexibility, and advanced reeling technology to enhance operational performance.

This article explores the features, applications, and benefits of 2YSLGCGOEU winding cables, demonstrating how they address critical challenges like downtime, safety concerns, and cost efficiency, ultimately improving productivity across multiple industries.

Heavy-duty equipment used in mining, ports, and construction faces numerous challenges:

Harsh Operating Conditions

Frequent Cable Movement and Abrasion

High Power and Signal Requirements

Safety Risks

Traditional cables often fail under these intense conditions, causing:

Operational Delays

Increased Maintenance Costs

Safety Hazards

The 2YSLGCGOEU winding cable offers a comprehensive solution, tailored for high-performance durability, flexibility, and long-lasting reliability.

| Feature | Benefit |

|---|---|

| Exceptional Flexibility | Ensures reliable performance in dynamic winding and reeling applications. |

| Superior Durability | Withstands mechanical stress, frequent bending, and reeling operations. |

| Resistance to Harsh Conditions | Protects against abrasion, oil, chemicals, and extreme temperatures. |

| Advanced Reeling Technology | Optimized for smooth and continuous winding operations. |

| Enhanced Electrical Conductivity | Provides efficient power and signal transmission with minimal losses. |

| Long Service Life | Reduces replacement frequency, lowering maintenance costs. |

The superior performance of 2YSLGCGOEU winding cables stems from their specialized construction:

| Component | Material | Function |

|---|---|---|

| Conductor | Stranded Tinned Copper | High conductivity with resistance to corrosion. |

| Insulation | Cross-linked Polyethylene (XLPE) | Withstands high temperatures and electrical stress. |

| Inner Sheath | Thermoplastic Elastomer (TPE) | Enhances mechanical protection and flexibility. |

| Reinforcement | Textile or Steel Braid | Provides tensile strength and impact resistance. |

| Outer Jacket | Polyurethane (PUR) | Ensures abrasion resistance and protection against oils and chemicals. |

In mining, cables must handle rugged conditions and deliver power to high-demand machinery like drills, loaders, and conveyors.

| Challenge | 2YSLGCGOEU Solution |

|---|---|

| High power demand | Efficiently transmits power with minimal energy loss. |

| Abrasion from rough surfaces | Outer PUR jacket resists cuts and wear. |

| Dynamic cable movement | Exceptional flexibility for frequent winding and reeling. |

Cranes, ship loaders, and container handlers depend on reliable cables for continuous operations.

| Challenge | 2YSLGCGOEU Solution |

|---|---|

| Saltwater and humidity exposure | Materials resistant to corrosion ensure long service life. |

| Heavy-duty reeling systems | Advanced reeling technology prevents tangling and damage. |

| Continuous operation | High reliability minimizes operational interruptions. |

Large-scale construction machinery like excavators, cranes, and concrete mixers benefit from robust cables.

| Challenge | 2YSLGCGOEU Solution |

|---|---|

| Mechanical stress | Reinforced construction handles high tensile loads. |

| Harsh outdoor conditions | Insulation and outer jacket protect against UV, oil, and chemicals. |

| Tight installation spaces | Low bending radius allows for compact routing. |

Specialized vehicles and machinery in manufacturing plants or logistical hubs need dependable cables for seamless operation.

| Challenge | 2YSLGCGOEU Solution |

|---|---|

| Frequent cable replacement | Long-lasting materials reduce wear and maintenance needs. |

| Complex operational setups | Customizable lengths and configurations for specific requirements. |

| Aspect | Traditional Cables | 2YSLGCGOEU Cables |

|---|---|---|

| Durability | Prone to wear and failure | Engineered for extreme conditions |

| Flexibility | Limited | Highly flexible for reeling and bending |

| Maintenance Frequency | High | Minimal maintenance required |

| Cost Efficiency | Higher overall costs | Significant long-term savings |

Frequent cable failures in heavy-duty operations can cost thousands per day. The durability and reliability of 2YSLGCGOEU cables reduce unexpected interruptions.

Advanced insulation and robust outer jackets prevent electrical accidents, protecting both operators and equipment.

Efficient power delivery and long service life streamline operations and lower operating costs.

2YSLGCGOEU winding cables meet stringent industry standards, including:

| Specification | Details |

|---|---|

| Voltage Rating | Up to 10 kV |

| Temperature Range | -40°C to +90°C |

| Bending Radius | 5x cable diameter |

| Outer Jacket Material | Polyurethane (PUR) |

| Conductor Material | Tinned Copper |

| Aspect | Best Practice |

|---|---|

| Installation | Ensure proper tension to avoid overstretching. |

| Inspection | Regularly check for signs of wear, abrasion, or damage. |

| Storage | Store in dry, temperature-controlled areas away from direct sunlight. |

| Aspect | Traditional Cables | 2YSLGCGOEU Cables |

|---|---|---|

| Initial Cost | Lower | Moderate |

| Maintenance Costs | High | Minimal |

| Service Life | Short | Long |

The 2YSLGCGOEU winding cable is a robust, flexible, and high-performing solution for heavy-duty industrial transportation equipment. Its ability to operate in harsh conditions while reducing downtime and maintenance costs makes it an invaluable asset for industries.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.