Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™ Mining

Certification: VDE 0250 Part 814

Model Number: NSSHCGEOEU

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-60 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 18,000 meters per week

Permissible Tensile Fore: |

MAX 1350N |

Flexibility: |

Highly Flexible |

Robust Durality: |

Heavy-duty Construction |

Abrasion Resistance: |

High |

Tensile Strength: |

2000 Lbs |

Stockyard Management: |

Organizes Material Storage |

Cable Flame Retardant: |

Yes |

Industrial Strength: |

Built For Heavy Industrial Use |

Jacket Material: |

Neoprene |

Oil Resistance: |

Yes |

Permissible Tensile Fore: |

MAX 1350N |

Flexibility: |

Highly Flexible |

Robust Durality: |

Heavy-duty Construction |

Abrasion Resistance: |

High |

Tensile Strength: |

2000 Lbs |

Stockyard Management: |

Organizes Material Storage |

Cable Flame Retardant: |

Yes |

Industrial Strength: |

Built For Heavy Industrial Use |

Jacket Material: |

Neoprene |

Oil Resistance: |

Yes |

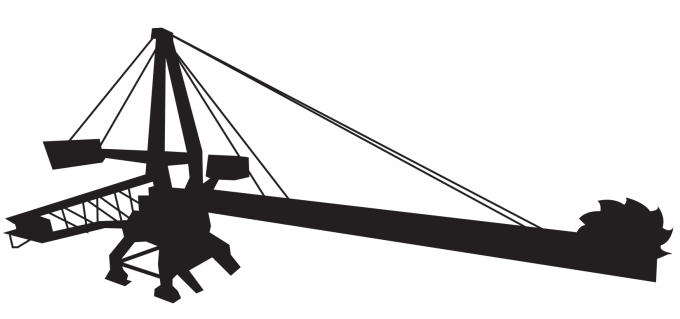

The demands of long-arm mining excavators operating in North America and Europe require cutting-edge solutions for durability, safety, and reliability. The NSSHCGEOEU cable has emerged as an ideal choice, addressing challenges like harsh environments, frequent mechanical stress, and high electrical demands.

This article explores the features, benefits, and applications of NSSHCGEOEU cables, demonstrating how they enhance productivity, minimize downtime, and ensure safety in industrial mining operations.

Operating in mining environments poses unique challenges for equipment and cabling systems:

Traditional cables often fail to meet the stringent demands of mining applications. The NSSHCGEOEU cable, designed specifically for mining, offers enhanced performance, ensuring long-lasting operation in even the harshest conditions.

| Feature | Benefit |

|---|---|

| Exceptional Flexibility | Ensures smooth operation with frequent cable movement. |

| Abrasion Resistance | Reduces wear and tear caused by rough terrain and machinery motion. |

| Chemical Resistance | Protects against oils, chemicals, and other corrosive substances common in mining sites. |

| Temperature Resilience | Operates effectively across extreme temperatures (-40°C to +85°C). |

| High Tensile Strength | Withstands mechanical stress during extended operations. |

| Enhanced Conductivity | Provides efficient power transmission with minimal energy loss. |

| Long Service Life | Reduces the need for frequent replacements, lowering maintenance costs. |

| Component | Material | Purpose |

|---|---|---|

| Outer Jacket | Chloroprene Rubber (CR) | Protects against abrasion, chemicals, and environmental elements. |

| Insulation | Ethylene-Propylene Rubber (EPR) | Ensures high electrical insulation and thermal stability. |

| Conductor | Fine-Stranded Copper | Delivers superior conductivity and flexibility. |

| Reinforcement | Textile or steel braiding | Increases tensile strength and durability under dynamic stress. |

| Shielding | Copper Braiding | Minimizes electromagnetic interference, ensuring reliable data transmission. |

NSSHCGEOEU cables reliably deliver high-voltage electricity, powering the essential components of excavators, including motors and hydraulic systems.

| Power Specifications | Details |

|---|---|

| Voltage Rating | Up to 1.1 kV |

| Current Capacity | Customizable based on equipment needs |

These cables support precise control of excavator movements, allowing operators to maneuver effectively and perform complex tasks.

Real-time monitoring of excavator performance is enabled by NSSHCGEOEU cables, which support:

| Aspect | NSSHCGEOEU Cables | Traditional Cables |

|---|---|---|

| Flexibility | High, supports dynamic reeling. | Limited, prone to damage. |

| Abrasion Resistance | Excellent. | Moderate, requires frequent repair. |

| Chemical Resistance | High. | Low, deteriorates quickly. |

| Service Life | Extended. | Short, frequent replacements needed. |

Frequent cable failures disrupt operations, but NSSHCGEOEU cables minimize interruptions due to their durability and high-quality design.

| Downtime Factor | Impact | NSSHCGEOEU Solution |

|---|---|---|

| Mechanical Stress | Frequent breaks in cables. | High tensile strength withstands stress. |

| Electrical Failures | Equipment damage and risks. | Reliable insulation prevents faults. |

The cables’ flame-retardant properties and high-quality insulation ensure worker and equipment safety.

Consistent power supply and low maintenance contribute to smoother operations and higher productivity.

NSSHCGEOEU cables are designed for extended use, reducing waste associated with frequent replacements.

The cables meet stringent industry standards, ensuring safe and sustainable operations:

| Specification | Details |

|---|---|

| Voltage Rating | Up to 1.1 kV |

| Temperature Range | -40°C to +85°C |

| Bending Radius | 12x cable diameter (dynamic) |

| Flame Retardancy | IEC 60332-1 compliant |

| Outer Jacket Material | Chloroprene Rubber (CR) |

| Factor | Traditional Cables | NSSHCGEOEU Cables |

|---|---|---|

| Initial Cost | Lower upfront. | Higher upfront. |

| Maintenance Costs | High, due to frequent failures. | Low, thanks to durable design. |

| Operational Downtime | Significant. | Minimal. |

| Total Cost Over Time | Higher overall. | Lower, with reduced replacements and downtime. |

NSSHCGEOEU cables are an indispensable solution for long-arm mining excavators, offering unparalleled durability, reliability, and safety. Designed to perform under the most challenging conditions, they provide a cost-effective and efficient option for mining operations in North America and Europe.

Advances in cable technology will further enhance performance, including higher capacities for data transmission, improved environmental sustainability, and integration with smart mining systems.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.