Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™ Reeling Cable

Certification: VDE 0250 Part 814

Model Number: FeiChun CRANEFLEX Reeling Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 16,000 meters per week

Bulk Cargo System: |

Supports Cargo Management |

Efficient Stockpiling: |

Optimizes Material Storage |

Jacket Material: |

5GM3/5GM5 RUBBER |

Material Handling System: |

Streamlines Operations |

Material Reclaiming: |

Ensures Effective Retrieval |

Bulk Cargo Transport: |

Facilitates Efficient Transport |

Bending Radius: |

6 X Cable Diameter |

Application: |

For Use In Reeling And Drum Applications |

Stacker And Reclaimer: |

Integral For Both Functions |

Flexibility: |

Highly Flexible |

Bulk Cargo System: |

Supports Cargo Management |

Efficient Stockpiling: |

Optimizes Material Storage |

Jacket Material: |

5GM3/5GM5 RUBBER |

Material Handling System: |

Streamlines Operations |

Material Reclaiming: |

Ensures Effective Retrieval |

Bulk Cargo Transport: |

Facilitates Efficient Transport |

Bending Radius: |

6 X Cable Diameter |

Application: |

For Use In Reeling And Drum Applications |

Stacker And Reclaimer: |

Integral For Both Functions |

Flexibility: |

Highly Flexible |

Modern port and industrial operations demand power and control cables that are robust, reliable, and capable of withstanding harsh environmental conditions.

The FeiChun CRANEFLEX 3.6/6kV Enhanced UV-Resistant Reeling Cable offers exceptional performance in reeling systems, especially for applications requiring consistent movement, high electrical loads, and exposure to UV radiation and severe weather.

With its 4x150mm² phase conductors and 2(2x75mm²) auxiliary conductors, the CRANEFLEX cable is tailored for ship-to-shore cranes, gantry cranes, and reeling drum systems.

It provides optimal flexibility, durability, and safety, making it the cable of choice for industries where high mechanical and electrical stresses are the norm.

The FeiChun CRANEFLEX Cable is purpose-built for dynamic, high-performance environments, including:

The CRANEFLEX Cable combines advanced materials and manufacturing techniques to deliver outstanding reliability and operational excellence. Below are the key technical specifications:

| Component | Material | Features and Benefits |

|---|---|---|

| Phase Conductors | Tinned copper, class 5 (IEC 60228) | Provides high electrical conductivity and corrosion resistance. |

| Auxiliary Conductors | 2x75mm² tinned copper | Ensures stable auxiliary power and signal transmission for crane control systems. |

| Insulation | EPR (Ethylene Propylene Rubber) | Offers excellent thermal and electrical performance under continuous operation. |

| Central Filler | Reinforced semiconductive compound | Enhances cable stability and prevents mechanical deformation during reeling operations. |

| Inner Sheath | Halogen-free rubber compound | Ensures internal protection and environmental safety. |

| Outer Sheath | UV-resistant polyurethane (PUR) | Resists wear, UV radiation, and environmental stress, extending cable lifespan. |

| Voltage Rating | 3.6/6kV | Suitable for medium-voltage applications in reeling systems. |

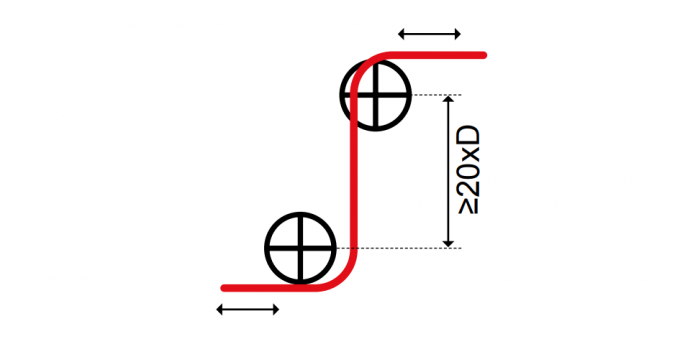

| Bending Radius | 6x Ø (fixed installation), 10x Ø (mobile) | Ideal for dynamic reeling applications. |

| Temperature Range | -40°C to +80°C | Reliable performance in extreme weather conditions. |

| Flame Resistance | IEC 60332-1 | Meets international safety standards for fire retardancy. |

The polyurethane outer sheath of the CRANEFLEX Cable is specially formulated to withstand prolonged UV exposure, ensuring a long service life even under direct sunlight.

This makes it an ideal choice for outdoor crane systems in ports and heavy industries.

With its class 5 tinned copper conductors and robust internal design, the cable offers unparalleled flexibility. This ensures smooth operation in reeling and unreeling systems, minimizing wear and tear.

The cable’s central filler and reinforced sheath make it capable of handling extreme tensile forces, torsion, and abrasion. It is designed to perform under high-speed reeling and repeated dynamic movements.

Constructed with halogen-free materials, the CRANEFLEX Cable reduces toxic gas emissions during combustion. This ensures safety for personnel and compliance with stringent environmental standards.

The use of EPR insulation provides excellent dielectric strength, ensuring consistent electrical performance under high-voltage and high-load conditions.

The FeiChun CRANEFLEX Cable is designed to address critical challenges faced by port and industrial operators:

| Problem | CRANEFLEX Solution |

|---|---|

| UV Degradation | Enhanced UV-resistant polyurethane sheath ensures long-term durability. |

| Frequent Wear and Tear | Superior abrasion resistance minimizes maintenance costs and downtime. |

| Dynamic Movements Under Load | Flexible design accommodates torsion, bending, and tension in reeling systems. |

| Harsh Weather Conditions | Operates reliably in temperatures from -40°C to +80°C. |

| Electrical Failures Due to Corrosion | Tinned copper conductors offer excellent corrosion resistance. |

| Safety Concerns | Halogen-free materials and flame retardant design enhance operational safety. |

| Parameter | Specification |

|---|---|

| Voltage Rating | 3.6/6kV |

| Conductor Configuration | 4x150mm² + 2(2x75mm²) |

| Outer Sheath Material | UV-resistant polyurethane (halogen-free) |

| Temperature Range | -40°C to +80°C |

| Bending Radius | 6x Ø (fixed), 10x Ø (mobile) |

| Chemical Resistance | Resistant to oils, chemicals, and UV exposure |

| Flame Retardant | IEC 60332-1 |

| Conductor Type | Tinned copper, class 5 |

| Insulation Material | EPR |

| Operational Stress Tolerance | High resistance to torsion and mechanical loads |

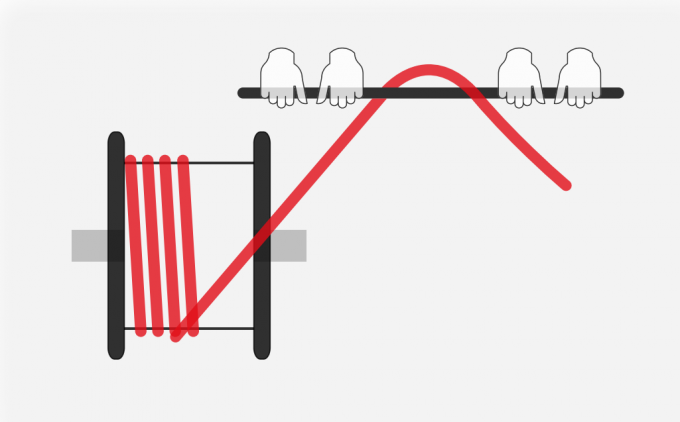

Proper installation and maintenance are key to ensuring the longevity and optimal performance of the CRANEFLEX Cable. Here are expert tips for its use:

| Installation Aspect | Recommendation |

|---|---|

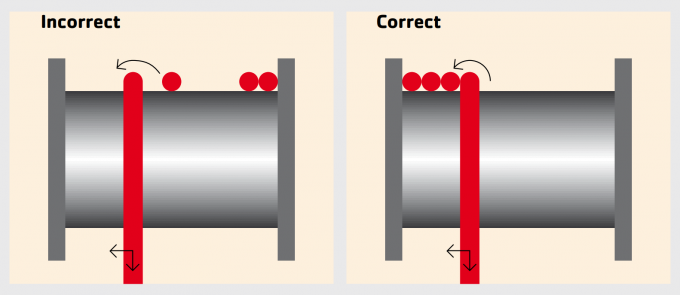

| Alignment of Reeling System | Ensure proper alignment to avoid excessive tension or twisting. |

| Bending Radius | Maintain a bending radius of 10x Ø during dynamic operations. |

| Temperature Considerations | Install and operate within the specified range of -40°C to +80°C. |

| Protective Measures | Use protective coverings in areas with potential for impact or sharp edges. |

| Periodic Maintenance | Inspect for wear or damage regularly, particularly in high-use environments. |

In bustling port environments, the CRANEFLEX Cable ensures uninterrupted power and control for container cranes operating under high-speed reeling conditions. Its UV-resistant outer sheath protects against prolonged exposure to sunlight.

For industrial operations requiring dynamic cable management, the CRANEFLEX Cable provides reliable performance, reducing downtime and enhancing efficiency.

The cable’s ability to withstand mechanical stresses and harsh conditions makes it ideal for reeling applications in mining equipment.

UV-Resistant Durability: Superior polyurethane sheath ensures long service life outdoors.

Unmatched Flexibility: Designed to handle the dynamic demands of reeling systems.

Safety First: Halogen-free and flame-retardant materials prioritize safety and compliance.

Operational Reliability: Performs exceptionally under extreme mechanical and environmental conditions.

Proven Track Record: Trusted by industry leaders worldwide for high-performance crane systems.

The FeiChun CRANEFLEX 3.6/6kV 4x150mm²+2(2x75mm²) Enhanced UV-Resistant Reeling Cable represents the pinnacle of engineering for demanding industrial and port applications. Its durable design, exceptional flexibility, and UV-resistant properties make it the perfect choice for operations requiring continuous movement and reliability.

Whether you operate in a port terminal, mining facility, or industrial setting, the CRANEFLEX Cable delivers unmatched performance and peace of mind. Contact us today to learn how FeiChun Cables can enhance your operations and keep your systems running smoothly!

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.