Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: Type 240 Mining Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: Contact Our Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer

Long Service Life: |

Built For Longevity |

Highly Reliable: |

Trustworthy In Critical Tasks |

Flame Retardant: |

Meets Flame Retardant Standards |

High Voltage Capacity: |

Voltage Resilience For Mining |

Jacket: |

Special Material |

Grounding Features: |

Includes Grounding For Added Safety |

Certifications: |

MSHA, CSA, UL |

Insulation: |

Special Material |

Abrasion Resistance: |

High |

Suitable For: |

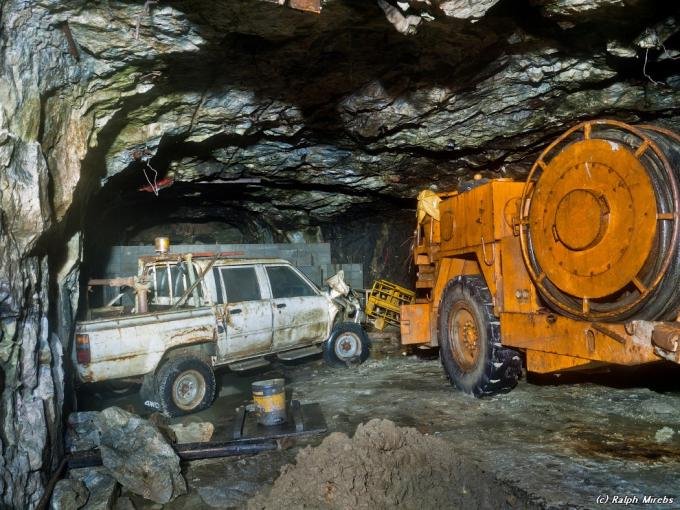

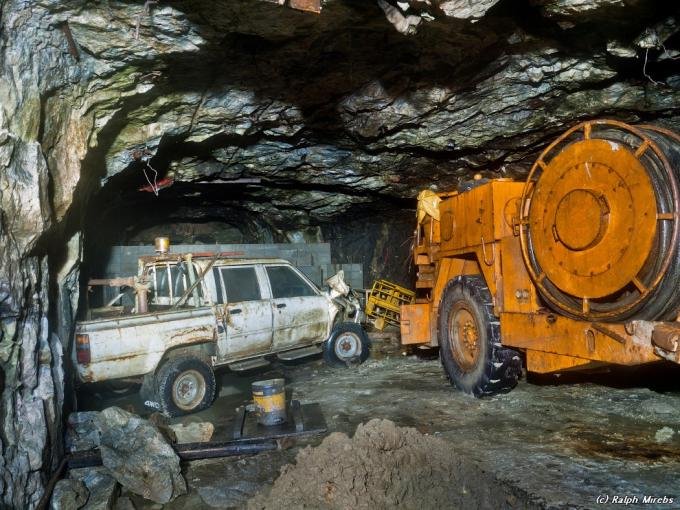

Underground Mining Applications |

Cable Type: |

Traction Mining Cable |

Bending Radius: |

10 X Cable Diameter |

Long Service Life: |

Built For Longevity |

Highly Reliable: |

Trustworthy In Critical Tasks |

Flame Retardant: |

Meets Flame Retardant Standards |

High Voltage Capacity: |

Voltage Resilience For Mining |

Jacket: |

Special Material |

Grounding Features: |

Includes Grounding For Added Safety |

Certifications: |

MSHA, CSA, UL |

Insulation: |

Special Material |

Abrasion Resistance: |

High |

Suitable For: |

Underground Mining Applications |

Cable Type: |

Traction Mining Cable |

Bending Radius: |

10 X Cable Diameter |

In the demanding world of open-pit coal mining, where equipment is subject to extreme conditions, the importance of reliable and durable cables cannot be overstated. Enter the Type 240 Mining Cable—a versatile solution designed specifically for open-pit coal mines.

This cable not only meets the rigorous demands of the industry but also exceeds expectations with its use of R-EP-90 insulation, providing superior protection and performance.

Australia's open-pit coal mines are renowned for their scale and intensity, often requiring machinery and infrastructure that can handle significant wear and tear.

The Type 240 Mining Cable is engineered to thrive in such environments, delivering exceptional reliability even under the most challenging conditions. Whether it’s powering heavy machinery or providing a stable electrical connection across vast distances, this cable is built to last.

Open-pit coal mining operations are particularly tough on equipment, with cables needing to withstand extreme temperatures, mechanical stress, and exposure to harsh environmental conditions. The Type 240 Mining Cable has been rigorously tested to ensure it can withstand these demands, making it a dependable choice for any mining operation.

One of the standout features of the Type 240 Mining Cable is its use of R-EP-90 insulation.

This material is far superior to more commonly used insulations like XLPE or 3GI3 in mining applications, particularly in open-pit mining where conditions can be extremely harsh.

R-EP-90 insulation is a high-performance rubber compound that offers exceptional resistance to heat, abrasion, and chemical exposure. It is designed to maintain its integrity even under the most extreme conditions, ensuring that the cable remains functional and safe throughout its operational life.

The "90" in R-EP-90 refers to its ability to withstand continuous temperatures of up to 90°C without degrading. This makes it particularly suitable for open-pit mining, where cables can be exposed to intense heat from the sun, heavy machinery, and even underground thermal activity.

R-EP-90 insulation offers several significant advantages over XLPE (Cross-Linked Polyethylene) and 3GI3 insulations, making it the preferred choice for demanding mining applications:

Superior Heat Resistance:

While XLPE and 3GI3 can also handle elevated temperatures, R-EP-90 offers superior heat resistance, particularly in environments where temperatures can exceed 90°C. This makes it a safer and more reliable choice for open-pit coal mines.

Enhanced Durability:

R-EP-90 insulation is more resistant to abrasion and mechanical stress than XLPE or 3GI3. This durability is crucial in mining environments where cables are often dragged across rough surfaces or subjected to heavy impacts.

Chemical Resistance:

Open-pit mining operations often involve exposure to chemicals, whether from the mining process itself or from environmental contaminants. R-EP-90 is highly resistant to chemicals, ensuring that the insulation remains intact and effective even in the harshest conditions.

Improved Flexibility:

Unlike XLPE, which can become brittle in low temperatures or after prolonged exposure to UV light, R-EP-90 remains flexible and resilient. This is particularly important in mining applications where cables need to be routed through tight spaces or around obstacles.

In Australia, where mining is a major industry, safety and compliance with national standards are paramount.

The Type 240 Mining Cable is fully compliant with Australian mining cable standards, ensuring that it meets all the necessary requirements for safe and effective use in open-pit coal mining operations.

These standards cover a wide range of factors, including:

Electrical Performance:

The Type 240 Mining Cable is designed to deliver reliable electrical performance, ensuring consistent power supply to all connected equipment.

Safety:

Compliance with Australian standards means that the cable has been rigorously tested for safety, including its resistance to fire, heat, and mechanical damage.

Durability:

The Type 240 Mining Cable is built to last, with a design that minimizes the risk of failure even under the most challenging conditions.

By choosing a cable that complies with these standards, mining operators can have confidence that they are using a product that is not only effective but also safe and reliable.

The Type 240 Mining Cable is a versatile solution for a wide range of open-pit coal mining applications.

Whether you’re powering draglines, excavators, conveyors, or other heavy machinery, this cable delivers the reliability and performance you need to keep your operations running smoothly.

Heavy machinery like draglines and excavators are the workhorses of open-pit mining, and they require a stable and reliable power supply to operate effectively.

The Type 240 Mining Cable is up to the task, providing consistent electrical power even under the most demanding conditions.

Thanks to its R-EP-90 insulation, the cable is protected against the heat generated by these massive machines, as well as the mechanical stress of being constantly moved and repositioned.

This makes it an ideal choice for powering the heavy machinery that is essential to open-pit coal mining operations.

Conveyor systems are critical for transporting coal from the mine site to processing facilities, and they require a robust and reliable electrical connection to operate efficiently.

The Type 240 Mining Cable is designed to handle the high power demands of these systems, ensuring that your conveyor lines remain operational and productive.

With its superior abrasion resistance and chemical resistance, the Type 240 Mining Cable is well-suited for use in conveyor systems that are exposed to the harsh conditions of open-pit mining.

Its durability ensures that it can withstand the wear and tear of continuous operation, reducing the risk of downtime and costly repairs.

Safety is always a top priority in mining operations, and the Type 240 Mining Cable contributes to a safer working environment in several key ways:

Fire Resistance:

The R-EP-90 insulation used in this cable is designed to be highly fire-resistant, reducing the risk of fire in the event of a short circuit or electrical fault. This is particularly important in open-pit coal mines, where the presence of flammable materials can make fires especially dangerous.

Mechanical Protection:

The Type 240 Mining Cable is built to withstand the mechanical stresses of open-pit mining, including impacts, abrasion, and crushing forces. This reduces the risk of cable failure, which can lead to dangerous situations such as electrical faults or equipment malfunctions.

Chemical Resistance:

The cable’s R-EP-90 insulation provides excellent protection against chemicals, ensuring that the insulation remains intact and effective even in environments where exposure to chemicals is a concern. This further enhances the safety of the cable, reducing the risk of insulation failure and subsequent electrical hazards.

In open-pit coal mining, the choice of cable can have a significant impact on the efficiency, safety, and reliability of your operations.

The Type 240 Mining Cable stands out as an excellent choice for several reasons:

Superior Insulation:

The use of R-EP-90 insulation provides unmatched protection against heat, abrasion, and chemicals, making this cable a reliable and durable option for open-pit mining applications.

Compliance with Australian Standards:

This cable meets all relevant Australian mining standards, ensuring that it is safe and effective for use in open-pit coal mines.

Versatility:

The Type 240 Mining Cable is suitable for a wide range of applications, from powering heavy machinery to connecting conveyor systems, making it a versatile solution for any mining operation.

When it comes to choosing a cable for open-pit coal mining operations, the Type 240 Mining Cable is an outstanding choice.

Its R-EP-90 insulation offers superior protection against the harsh conditions typically encountered in these environments, while its compliance with Australian standards ensures that it is safe and reliable.

By investing in the Type 240 Mining Cable, mining operators can enjoy the peace of mind that comes with knowing they are using a high-quality, durable product that will perform reliably even under the most challenging conditions.

Whether you’re powering heavy machinery, connecting conveyor systems, or enhancing safety in your mining operations, the Type 240 Mining Cable delivers the performance and protection you need to keep your operations running smoothly.

The Type 240 Mining Cable is designed specifically for the harsh conditions of open-pit coal mining. It features R-EP-90 insulation, which offers superior protection against heat, abrasion, and chemicals, ensuring reliable performance even in the most challenging environments.

Additionally, this cable is fully compliant with Australian mining cable standards, making it a safe and reliable choice for mining operations.

R-EP-90 insulation offers several advantages over XLPE and 3GI3 insulations, including better heat resistance, enhanced durability, and superior chemical resistance.

These properties make R-EP-90 the ideal insulation material for open-pit coal mining applications, where cables are exposed to extreme conditions.

Yes, the Type 240 Mining Cable is fully compliant with Australian mining cable standards.

This ensures that it meets all necessary safety and performance requirements for use in open-pit coal mining operations.

While the Type 240 Mining Cable is specifically designed for open-pit coal mining, its versatility makes it suitable for a wide range of mining applications.

It can be used to power heavy machinery, connect conveyor systems, and more, making it a valuable addition to any mining operation.

| Power Cores | Core screen | Pilot cores | Sheath | Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crosssection mm2 |

Strand no/mm |

Conductor Diameter Nom. mm |

Insulation thickness mm |

Insulation diameter Nom. mm |

Braid wires no/mm |

Crosssection mm2 |

Strand Min.no/mm |

Insulation thickness mm |

Thickness mm |

Overall diameter Nom. Mm |

Approx. cable weight kg/km |

Copper weight kg/km |

| Type | 240.1 | 1.1/1.1kV | ||||||||||

| 6 | 84/0.30 | 3.4 | 1.5 | 6.5 | 7/0.25 | 7.2 | 15/0.30 | 1 | 3.8 | 30 | 1.35 | 418 |

| 10 | 77/0.40 | 4.6 | 1.5 | 7.7 | 7/0.25 | 8.6 | 24/0.30 | 1 | 3.8 | 32.6 | 1.65 | 594 |

| 16 | 126/0.40 | 5.7 | 1.6 | 9 | 7/0.25 | 9.6 | 39/0.30 | 1 | 4 | 35.8 | 2.05 | 824 |

| 25 | 209/0.40 | 7.2 | 1.6 | 10.5 | 7/0.25 | 11.3 | 63/0.30 | 1.2 | 4.3 | 39.7 | 2.7 | 1.181 |

| 35 | 285/0.40 | 8.5 | 1.6 | 11.8 | 7/0.25 | 12.4 | 87/0.30 | 1.2 | 4.6 | 43.1 | 3.25 | 1.55 |

| 50 | 380/0.40 | 10 | 1.7 | 13.5 | 7/0.25 | 14.1 | 114/0.30 | 1.2 | 5 | 47.7 | 4.05 | 2.091 |

| 70 | 203/0.67 | 12 | 1.8 | 16 | 7/0.25 | 16.5 | 36/0.67 | 1.2 | 5.4 | 53.9 | 5.4 | 2.889 |

| 95 | 259/0.67 | 13.2 | 2 | 17.6 | 7/0.25 | 18.2 | 36/0.67 | 1.2 | 6 | 58.6 | 6.45 | 3.658 |

| 120 | 336/0.67 | 15.3 | 2.1 | 20 | 7/0.25 | 20.3 | 39/0.67 | 1.4 | 6.4 | 64.4 | 7.8 | 4.47 |

| 150 | 427/0.67 | 17.1 | 2.3 | 22.2 | 7/0.25 | 22.3 | 48/0.67 | 1.4 | 6.9 | 70.2 | 9.5 | 5.513 |

| 185 | 518/0.67 | 19.2 | 2.5 | 24.7 | 7/0.30 | 30.2 | 63/0.67 | 1.4 | 7.4 | 77.4 | 11.5 | 6.84 |

| 240 | 672/0.67 | 21.8 | 2.8 | 27.9 | 7/0.30 | 33.6 | 77/0.67 | 1.6 | 8.2 | 86 | 14.4 | 8.664 |

| 300 | 854/0.67 | 24.4 | 3 | 30.9 | 7/0.40 | 50.1 | 98/0.67 | 1.6 | 8.8 | 95.1 | 18.1 | 11.08 |

| Type | 240.3 | 3.3/3.3kV | ||||||||||

| 16 | 126/0.40 | 5.7 | 3 | 12.5 | 7/0.25 | 13.1 | 39/0.30 | 1.4 | 5.3 | 46.2 | 3.05 | 925 |

| 25 | 209/0.40 | 7.2 | 3 | 14 | 7/0.25 | 14.8 | 63/0.30 | 1.4 | 5.6 | 50.1 | 3.8 | 1.282 |

| 35 | 285/0.40 | 8.5 | 3 | 15.3 | 7/0.25 | 15.8 | 87/0.30 | 1.4 | 5.9 | 53.5 | 4.45 | 1.648 |

| 50 | 380/0.40 | 10 | 3 | 16.8 | 7/0.25 | 17.2 | 114/0.30 | 1.4 | 6.3 | 57.6 | 5.25 | 2.181 |

| 70 | 203/0.67 | 12 | 3 | 18.8 | 7/0.25 | 18.6 | 36/0.67 | 1.4 | 6.6 | 62.5 | 6.6 | 2.95 |

| 95 | 259/0.67 | 13.2 | 3 | 20 | 7/0.25 | 20.3 | 36/0.67 | 1.4 | 7.1 | 66.2 | 7.55 | 3.719 |

| 120 | 336/0.67 | 15.3 | 3 | 22.1 | 7/0.30 | 27.2 | 39/0.67 | 1.6 | 7.4 | 72 | 9.15 | 4.669 |

| 150 | 427/0.67 | 17.1 | 3 | 23.9 | 7/0.40 | 39.6 | 48/0.67 | 1.6 | 7.8 | 78 | 11.2 | 6.011 |

| 185 | 518/0.67 | 19.2 | 3 | 26 | 7/0.40 | 42.2 | 63/0.67 | 1.8 | 8.2 | 83.4 | 12.9 | 7.186 |

| 240 | 672/0.67 | 21.8 | 3 | 28.6 | 7/0.40 | 46.6 | 77/0.67 | 1.8 | 8.8 | 90.3 | 15.6 | 9.038 |

| 300 | 854/0.67 | 24.4 | 3 | 31.2 | 7/0.50 | 63.2 | 98/0.67 | 1.8 | 9.4 | 98.4 | 19.2 | 11.457 |

| Type | 240.6 | 6.6/6.6kV | ||||||||||

| 16 | 126/0.40 | 5.7 | 5 | 16.5 | 7/0.25 | 17.2 | 39/0.30 | 1.4 | 6.4 | 57.3 | 4.45 | 1.043 |

| 25 | 209/0.40 | 7.2 | 5 | 18 | 7/0.25 | 18.6 | 63/0.30 | 1.4 | 6.7 | 61.2 | 5.25 | 1.392 |

| 35 | 285/0.40 | 8.5 | 5 | 19.3 | 7/0.25 | 18.6 | 87/0.30 | 1.6 | 7 | 64.6 | 6 | 1.728 |

| 50 | 380/0.40 | 10 | 5 | 20.8 | 7/0.25 | 21.3 | 114/0.30 | 1.6 | 7.3 | 68.5 | 6.9 | 2.299 |

| 70 | 203/0.67 | 12 | 5 | 22.8 | 7/0.25 | 23.4 | 36/0.67 | 1.6 | 7.7 | 73.7 | 8.35 | 3.088 |

| 95 | 259/0.67 | 13.2 | 5 | 24 | 7/0.30 | 29.2 | 36/0.67 | 1.6 | 8.1 | 77.8 | 9.65 | 3.975 |

| 120 | 336/0.67 | 15.3 | 5 | 26.1 | 7/0.30 | 31.7 | 39/0.67 | 1.8 | 8.5 | 83.1 | 11.2 | 4.799 |

| 150 | 427/0.67 | 17.1 | 5 | 27.9 | 7/0.40 | 45.7 | 48/0.67 | 1.8 | 8.9 | 89.1 | 13.5 | 6.187 |

| 185 | 518/0.67 | 19.2 | 5 | 30 | 7/0.40 | 48.4 | 63/0.67 | 1.8 | 9.3 | 94.5 | 15.3 | 7.365 |

| 240 | 672/0.67 | 21.8 | 5 | 32.6 | 7/0.40 | 52.8 | 77/0.67 | 1.8 | 9.9 | 101.4 | 18.1 | 9.216 |

| 300 | 854/0.67 | 24.4 | 5 | 35.2 | 7/0.50 | 71.5 | 98/0.67 | 1.8 | 10.4 | 109.3 | 21.9 | 11.696 |

| Type | 240.11 | 11/11kV | ||||||||||

| 25 | 209/0.40 | 7.2 | 7.6 | 23.4 | 7/0.25 | 23.7 | 63/0.30 | 2 | 8.1 | 75.6 | 7.6 | 1.538 |

| 35 | 285/0.40 | 8.5 | 7.6 | 24.7 | 7/0.30 | 30.2 | 87/0.30 | 2 | 8.4 | 79.7 | 8.7 | 2.063 |

| 50 | 380/0.40 | 10 | 7.6 | 26.2 | 7/0.30 | 31.7 | 114/0.30 | 2 | 8.7 | 83.6 | 9.75 | 2.598 |

| 70 | 203/0.67 | 12 | 7.6 | 28.2 | 7/0.30 | 34.1 | 36/0.67 | 2 | 9.1 | 88.8 | 11.4 | 3.396 |

| 95 | 259/0.67 | 13.2 | 7.6 | 29.4 | 7/0.40 | 47.5 | 36/0.67 | 2 | 9.6 | 93.7 | 13.2 | 4.502 |

| 120 | 336/0.67 | 15.3 | 7.6 | 31.5 | 7/0.40 | 51 | 39/0.67 | 2.2 | 9.9 | 98.8 | 14.9 | 5.354 |

| 150 | 427/0.67 | 17.1 | 7.6 | 33.3 | 7/0.40 | 53.7 | 48/0.67 | 2.2 | 10.3 | 103.5 | 16.8 | 6.417 |

| 185 | 518/0.67 | 19.2 | 7.6 | 35.4 | 7/0.40 | 57.2 | 63/0.67 | 2.2 | 10.7 | 108.8 | 18.8 | 7.618 |

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.