Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 1802 AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: AS/NZS 1802 Type 209 Mining Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: Contact Our Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer

Features: |

Oil And Flame Resistant, UV Resistant |

Suitable For: |

Underground Mining Applications |

Standards: |

ICEA S-75-381/NEMA WC58 |

Voltage Rating: |

600/1000V |

Robust Conductor: |

Efficient Conductive Material |

Temperature Rating: |

-40°C To 90°C |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Insulation: |

Special Material |

Optimized For Quarrying: |

Designed For Quarrying Applications |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Length: |

Customizable |

Maximum Tension: |

5000 Lbs |

Features: |

Oil And Flame Resistant, UV Resistant |

Suitable For: |

Underground Mining Applications |

Standards: |

ICEA S-75-381/NEMA WC58 |

Voltage Rating: |

600/1000V |

Robust Conductor: |

Efficient Conductive Material |

Temperature Rating: |

-40°C To 90°C |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Insulation: |

Special Material |

Optimized For Quarrying: |

Designed For Quarrying Applications |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Length: |

Customizable |

Maximum Tension: |

5000 Lbs |

When it comes to powering operations in underground coal mines, the choice of cable can make all the difference in terms of safety, reliability, and performance.

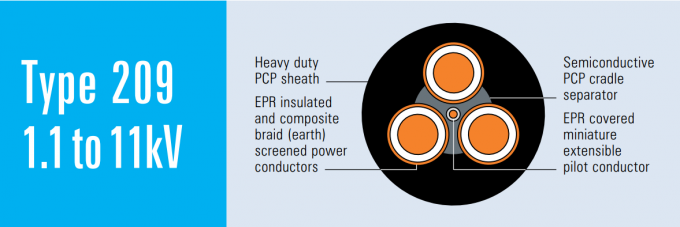

The Type 209 Cable, meticulously crafted to withstand the harshest conditions, is the ideal solution for environments where dust, moisture, and mechanical stress are ever-present challenges.

This cable not only meets but exceeds the stringent requirements of the AS/NZS 1802 standard, making it the perfect choice for surface open-pit mines, especially those in low-dimensional and high-sunlight environments. Its robust construction and UV-resistant properties ensure that it performs exceptionally well even in the toughest conditions.

The Type 209 Cable is specifically designed to address the unique challenges faced in underground coal mines.

Its advanced features provide superior protection against environmental factors and ensure that it delivers reliable performance day in and day out. Let’s dive into what makes this cable a standout choice for mining operations:

Dust and Moisture Resistance

Underground coal mines are notorious for their dusty, damp environments. The Type 209 Cable is engineered to resist the infiltration of dust and moisture, ensuring that the cable remains operational even in the most challenging conditions.

This is particularly important for maintaining electrical integrity and preventing short circuits that could lead to downtime or, worse, dangerous situations.

Superior Mechanical Strength

Mining operations involve a lot of heavy machinery and equipment, all of which put considerable mechanical stress on cables.

The Type 209 Cable is built to withstand these stresses without compromising its performance. Its rugged construction ensures that it can endure the physical demands of mining, including pulling, bending, and abrasion.

Compliance with AS/NZS 1802

The AS/NZS 1802 standard is the benchmark for mining cables in Australia and New Zealand. Cables that meet this standard have been rigorously tested for safety, durability, and performance in mining environments.

The Type 209 Cable not only meets but surpasses these standards, offering peace of mind that it will perform reliably under the most demanding conditions.

UV Resistance

Surface open-pit mines are often exposed to harsh sunlight, which can degrade standard cables over time. The Type 209 Cable features a UV-resistant outer sheath that protects it from the damaging effects of prolonged exposure to sunlight.

This makes it an excellent choice for mines located in regions with high levels of sunlight, ensuring a longer service life and reduced maintenance costs.

Adaptability to Various Environments

The Type 209 Cable is designed to be versatile, making it suitable for a wide range of mining environments. Whether your operation is in a low-dimensional mine with tight spaces or an open-pit mine exposed to the elements, this cable can adapt to meet your needs.

Its robust design and flexibility make it easy to install and maintain, even in challenging conditions.

The Type 209 Cable offers several features that make it the preferred choice for mining operations:

High-Quality Insulation:

The cable features premium-grade insulation that prevents electrical leakage and ensures safe, reliable power transmission.

Durable Sheath:

The outer sheath of the Type 209 Cable is made from a specially formulated material that resists cuts, abrasions, and UV radiation. This durability is crucial for maintaining the integrity of the cable in harsh mining environments.

Flexible Construction:

Despite its ruggedness, the Type 209 Cable is designed to be flexible enough to handle the tight bends and curves often required in mining applications. This flexibility makes installation easier and helps to reduce the risk of damage during operation.

Thermal Stability:

The cable is engineered to perform reliably in a wide range of temperatures, making it suitable for both underground and surface mining operations. Whether it’s exposed to the heat of the sun in an open-pit mine or the cool temperatures of an underground tunnel, the Type 209 Cable maintains its performance.

Resistance to Chemicals:

Mining environments often involve exposure to various chemicals that can degrade standard cables. The Type 209 Cable is resistant to oils, solvents, and other chemicals commonly found in mines, ensuring long-lasting performance.

Type-209.1-3C50-SQMM-Mining-Cable-Australia-Standa...

| Power Cores | Core screen | Pilot core | Sheath | Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Crosssection mm2 |

Strand no/mm |

Conductor Diameter Nom. mm |

Insulation thickness mm |

Insulation diameter Nom. mm |

Braid wires no/mm |

Crosssection mm |

Strand no/mm |

Insulation thickness mm |

Thickness mm |

Overall diameter Nom. Mm |

Approx. cable weight kg/km |

Copper weight kg/km |

| Type | 209.1 | 1.1/1.1kV | ||||||||||

| 6 | 84/0.30 | 3.4 | 1.5 | 6.5 | 7/0.25 | 7.2 | 24/0.20 | 0.8 | 3.8 | 30 | 1.3 | 388 |

| 10 | 77/0.40 | 4.6 | 1.5 | 7.7 | 7/0.25 | 8.6 | 24/0.20 | 0.8 | 3.8 | 32.6 | 1.6 | 543 |

| 16 | 126/0.40 | 5.7 | 1.6 | 9 | 7/0.25 | 9.6 | 24/0.20 | 0.8 | 4 | 35.8 | 2 | 745 |

| 25 | 209/0.40 | 7.2 | 1.6 | 10.5 | 7/0.25 | 11.3 | 24/0.20 | 0.8 | 4.3 | 39.7 | 2.6 | 1.053 |

| 35 | 285/0.40 | 8.5 | 1.6 | 11.8 | 7/0.25 | 12.4 | 24/0.20 | 0.8 | 4.6 | 43.1 | 3.1 | 1.373 |

| 50 | 380/0.40 | 10 | 1.7 | 13.5 | 7/0.25 | 14.1 | 40/0.20 | 0.8 | 5 | 47.7 | 3.85 | 1.859 |

| 70 | 203/0.67 | 12 | 1.8 | 16 | 7/0.25 | 16.5 | 40/0.20 | 0.8 | 5.4 | 53.9 | 5.1 | 2.504 |

| 95 | 259/0.67 | 13.2 | 2 | 17.6 | 7/0.25 | 18.2 | 40/0.20 | 0.8 | 6 | 58.6 | 6.1 | 3.273 |

| 120 | 336/0.67 | 15.3 | 2.1 | 20 | 7/0.25 | 20.3 | 40/0.20 | 0.8 | 6.4 | 64.4 | 7.5 | 4.053 |

| 150 | 427/0.67 | 17.1 | 2.3 | 22.2 | 7/0.25 | 22.3 | 40/0.20 | 0.8 | 6.9 | 70.2 | 9.05 | 4.975 |

| 185 | 518/0.67 | 19.2 | 2.5 | 24.7 | 7/0.30 | 30.2 | 40/0.20 | 0.8 | 7.4 | 77.4 | 11.1 | 6.21 |

| 240 | 672/0.67 | 21.8 | 2.8 | 27.9 | 7/0.30 | 33.6 | 40/0.20 | 0.8 | 8.2 | 86 | 13.8 | 7.892 |

| 300 | 854/0.67 | 24.4 | 3 | 30.9 | 7/0.40 | 50.1 | 40/0.20 | 0.8 | 8.8 | 95.1 | 17.4 | 10.095 |

| Type | 209.3 | 3.3/3.3kV | ||||||||||

| 16 | 126/0.40 | 5.7 | 3 | 12.5 | 7/0.25 | 13.1 | 24/0.20 | 0.8 | 5.3 | 46.2 | 3 | 846 |

| 25 | 209/0.40 | 7.2 | 3 | 14 | 7/0.25 | 14.8 | 24/0.20 | 0.8 | 5.6 | 50.1 | 3.7 | 1.154 |

| 35 | 285/0.40 | 8.5 | 3 | 15.3 | 7/0.25 | 15.8 | 24/0.20 | 0.8 | 5.9 | 53.5 | 4.3 | 1.471 |

| 50 | 380/0.40 | 10 | 3 | 16.8 | 7/0.25 | 17.2 | 40/0.20 | 0.8 | 6.3 | 57.6 | 5.1 | 1.948 |

| 70 | 203/0.67 | 12 | 3 | 18.8 | 7/0.25 | 18.6 | 40/0.20 | 0.8 | 6.6 | 62.5 | 6.25 | 2.564 |

| 95 | 259/0.67 | 13.2 | 3 | 20 | 7/0.25 | 20.3 | 40/0.20 | 0.8 | 7.1 | 66.2 | 7.25 | 3.333 |

| 120 | 336/0.67 | 15.3 | 3 | 22.1 | 7/0.30 | 27.2 | 40/0.20 | 0.8 | 7.4 | 72 | 8.8 | 4.252 |

| 150 | 427/0.67 | 17.1 | 3 | 23.9 | 7/0.40 | 39.6 | 40/0.20 | 0.8 | 7.8 | 78 | 10.8 | 5.473 |

| 185 | 518/0.67 | 19.2 | 3 | 26 | 7/0.40 | 42.2 | 40/0.20 | 0.8 | 8.2 | 83.4 | 12.5 | 6.556 |

| 240 | 672/0.67 | 21.8 | 3 | 28.6 | 7/0.40 | 46.6 | 40/0.20 | 0.8 | 8.8 | 90.3 | 15 | 8.267 |

| 300 | 854/0.67 | 24.4 | 3 | 31.2 | 7/0.50 | 63.2 | 40/0.20 | 0.8 | 9.4 | 98.4 | 18.4 | 10.473 |

| Type | 209.6 | 6.6/6.6kV | ||||||||||

| 16 | 126/0.40 | 5.7 | 5 | 16.5 | 7/0.25 | 17.2 | 24/0.20 | 0.8 | 6.4 | 57.3 | 4.4 | 964 |

| 25 | 209/0.40 | 7.2 | 5 | 18 | 7/0.25 | 18.6 | 24/0.20 | 0.8 | 6.7 | 61.2 | 5.15 | 1.263 |

| 35 | 285/0.40 | 8.5 | 5 | 19.3 | 7/0.25 | 18.6 | 24/0.20 | 0.8 | 7 | 64.6 | 5.85 | 1.551 |

| 50 | 380/0.40 | 10 | 5 | 20.8 | 7/0.25 | 21.3 | 40/0.20 | 0.8 | 7.3 | 68.5 | 6.7 | 2.066 |

| 70 | 203/0.67 | 12 | 5 | 22.8 | 7/0.25 | 23.4 | 40/0.20 | 0.8 | 7.7 | 73.7 | 8.05 | 2.702 |

| 95 | 259/0.67 | 13.2 | 5 | 24 | 7/0.30 | 29.2 | 40/0.20 | 0.8 | 8.1 | 77.8 | 9.35 | 3.589 |

| 120 | 336/0.67 | 15.3 | 5 | 26.1 | 7/0.30 | 31.7 | 40/0.20 | 0.8 | 8.5 | 83.1 | 10.9 | 4.381 |

| 150 | 427/0.67 | 17.1 | 5 | 27.9 | 7/0.40 | 45.7 | 40/0.20 | 0.8 | 8.9 | 89.1 | 13.1 | 5.649 |

| 185 | 518/0.67 | 19.2 | 5 | 30 | 7/0.40 | 48.4 | 40/0.20 | 0.8 | 9.3 | 94.5 | 14.8 | 6.734 |

| 240 | 672/0.67 | 21.8 | 5 | 32.6 | 7/0.40 | 52.8 | 40/0.20 | 0.8 | 9.9 | 101.4 | 17.5 | 8.445 |

| 300 | 854/0.67 | 24.4 | 5 | 35.2 | 7/0.50 | 71.5 | 40/0.20 | 0.8 | 10.4 | 109.3 | 21.2 | 10.712 |

| Type | 209.11 | 11/11kV | ||||||||||

| 25 | 209/0.40 | 7.2 | 7.6 | 23.4 | 7/0.25 | 23.7 | 24/0.20 | 0.8 | 8.1 | 75.6 | 7.5 | 1.41 |

| 35 | 285/0,40 | 8.5 | 7.6 | 24.7 | 7/0.30 | 30.2 | 24/0.20 | 0.8 | 8.4 | 79.7 | 8.6 | 1.885 |

| 50 | 380/0,40 | 10 | 7.6 | 26.2 | 7/0.30 | 31.7 | 40/0.20 | 0.8 | 8.7 | 83.6 | 9.6 | 2.365 |

| 70 | 203/0.67 | 12 | 7.6 | 28.2 | 7/0.30 | 34.1 | 40/0.20 | 0.8 | 9.1 | 88.8 | 11.1 | 3.011 |

| 95 | 259/0.67 | 13.2 | 7.6 | 29.4 | 7/0.40 | 47.5 | 40/0.20 | 0.8 | 9.6 | 93.7 | 12.9 | 4.116 |

| 120 | 336/0.67 | 15.3 | 7.6 | 31.5 | 7/0.40 | 51 | 40/0.20 | 0.8 | 9.9 | 98.8 | 14.6 | 4.937 |

| 150 | 427/0.67 | 17.1 | 7.6 | 33.3 | 7/0.40 | 53.7 | 40/0.20 | 0.8 | 10.3 | 103.5 | 16.4 | 5.879 |

| 185 | 518/0.67 | 19.2 | 7.6 | 35.4 | 7/0.40 | 57.2 | 40/0.20 | 0.8 | 10.7 | 108.8 | 18.3 | 6.988 |

The AS/NZS 1802 standard is the recognized benchmark for mining cables in Australia and New Zealand. Compliance with this standard means that the Type 209 Cable has been thoroughly tested to meet the highest levels of safety and performance.

Safety:

Cables that comply with AS/NZS 1802 have been tested for flame resistance, electrical integrity, and mechanical strength. This ensures that the cable can be used safely in environments where the risk of fire and electrical faults is high.

Reliability:

Compliance with this standard means that the cable will perform consistently, even under the most demanding conditions. This reliability is essential for mining operations, where downtime can be costly and dangerous.

Durability:

AS/NZS 1802 compliance also means that the cable is built to last. It has been tested for resistance to environmental factors like moisture, dust, and UV radiation, ensuring a long service life and reduced need for replacements.

The Type 209 Cable is versatile enough to be used in a wide range of mining applications. Here are some of the most common uses:

Underground Coal Mines:

The cable’s resistance to dust, moisture, and mechanical stress makes it ideal for use in underground coal mines. It ensures reliable power transmission in these challenging environments, helping to keep operations running smoothly.

Surface Open-Pit Mines:

Thanks to its UV-resistant sheath and robust construction, the Type 209 Cable is also well-suited for use in surface open-pit mines. It can withstand exposure to sunlight and the physical demands of open-pit mining, providing long-lasting performance.

Low-Dimensional Mining Operations:

The cable’s flexibility and adaptability make it an excellent choice for low-dimensional mines where space is limited. Its flexible construction allows it to be installed easily in tight spaces without compromising performance.

High-Sunlight Environments:

In regions where mines are exposed to intense sunlight, the Type 209 Cable offers the added benefit of UV resistance. This ensures that the cable remains functional and safe even after prolonged exposure to the sun’s rays.

In conclusion, the Type 209 Cable is meticulously crafted to meet the specific needs of underground coal mines and other mining operations. Its resistance to dust, moisture, mechanical stress, and UV radiation makes it the ideal choice for both underground and surface mines, particularly in low-dimensional and high-sunlight environments.

By complying with the AS/NZS 1802 standard, this cable offers superior safety, reliability, and durability, ensuring that it can withstand the demanding conditions of mining operations.

Whether you’re looking for a cable that can handle the rigors of underground coal mining or one that will perform reliably in an open-pit mine, the Type 209 Cable is the perfect choice.

Investing in the Type 209 Cable means investing in a product that is designed to deliver exceptional performance and longevity, helping to keep your mining operations running smoothly and safely.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.