Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Packaging Details: Cable Reels or Packaging Bags

Payment Terms: T/T, Western Union

Safety Compliant: |

Meets Safety Standards |

Insulation: |

Special Material |

Oil Resistance: |

Yes |

Armor: |

Galvanized Steel Wire Braid |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Material: |

Special Compounds |

Optimized For Quarrying: |

Designed For Quarrying Applications |

Safety Compliant: |

Meets Safety Standards |

Insulation: |

Special Material |

Oil Resistance: |

Yes |

Armor: |

Galvanized Steel Wire Braid |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Material: |

Special Compounds |

Optimized For Quarrying: |

Designed For Quarrying Applications |

When it comes to underground mining, the choice of cable is paramount. The harsh conditions and demanding environments require cables that are not only robust and durable but also capable of delivering consistent and reliable power to essential machinery.

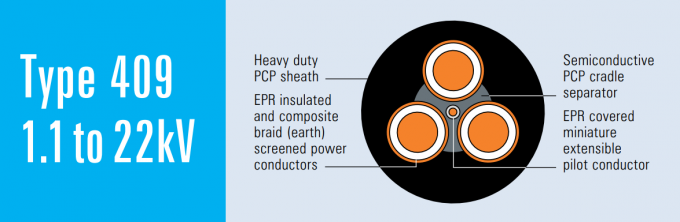

The Type 409 Mining Trailing Cable stands out as an ideal solution, specifically designed to power draglines, shovels, and drills in underground mining operations. Engineered to handle voltage ranges from 1.1kV to 22kV, this cable is built to perform under the toughest conditions while ensuring operational efficiency and safety.

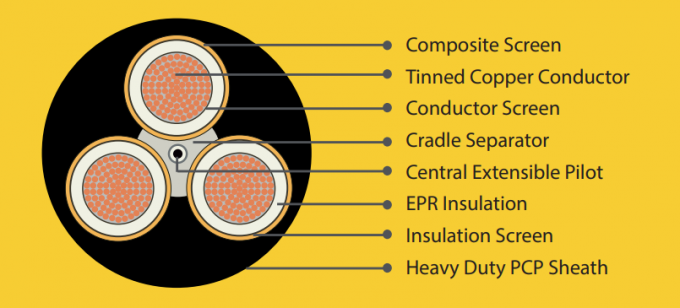

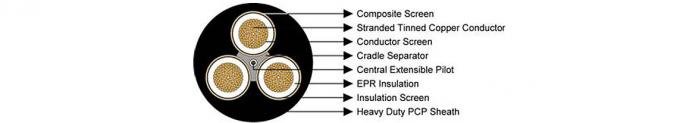

What makes the Type 409 Mining Trailing Cable particularly impressive is its use of EPR insulation, a PCP sheath, and a Center Extensible Pilot. These three components are crucial in maintaining the cable’s stability and reliability, even in the most challenging environments.

In this article, we’ll explore the key features of the Type 409 Cable and why it is the preferred choice for underground mining operations.

When selecting a cable for underground mining operations, several factors come into play, including durability, insulation, flexibility, and power capacity.

The Type 409 Mining Trailing Cable excels in all these areas, making it an exceptional choice for powering critical mining equipment.

EPR Insulation: Enhanced Electrical Performance

The Type 409 Cable is equipped with EPR (Ethylene Propylene Rubber) insulation, a material known for its excellent electrical properties and resistance to heat, chemicals, and moisture.

EPR insulation ensures that the cable can withstand high voltages and maintain stable electrical performance, even in harsh underground conditions.

This insulation material is particularly beneficial in mining environments where cables are often exposed to moisture and extreme temperatures. The result is a cable that delivers consistent power without the risk of electrical failure or degradation.

PCP Sheath: Superior Protection and Durability

The outer sheath of the Type 409 Cable is made from PCP (Polychloroprene), commonly known as Neoprene. PCP is chosen for its exceptional resistance to abrasion, chemicals, and weathering.

In underground mining, where cables are subjected to mechanical stress, rough handling, and harsh environmental conditions, the PCP sheath provides a robust protective layer that extends the cable’s lifespan.

Additionally, PCP offers excellent flexibility, allowing the cable to bend and maneuver around obstacles without compromising its integrity. This makes the Type 409 Cable easy to deploy and use in complex underground layouts.

Center Extensible Pilot: Stability and Reliability

A standout feature of the Type 409 Mining Trailing Cable is its Center Extensible Pilot. This component plays a critical role in maintaining the cable’s structural stability and ensuring reliable performance.

The Center Extensible Pilot allows for controlled elongation and flexibility, preventing internal stresses that could otherwise lead to damage or failure. In underground mining, where cables are often dragged, coiled, and subjected to constant movement, the Center Extensible Pilot ensures that the cable remains stable and functional throughout its use.

Voltage Range and Versatility

The Type 409 Cable is engineered to handle a wide range of voltages, from 1.1kV to 22kV. This versatility makes it suitable for powering various types of mining equipment, including draglines, shovels, drills, and other high-power machinery.

Whether you’re working with lower voltage equipment or need a cable that can handle higher voltage demands, the Type 409 Cable provides the flexibility and reliability you need to keep operations running smoothly.

Safety and Compliance

Safety is paramount in underground mining operations, and the Type 409 Mining Trailing Cable meets all relevant safety standards. Its combination of EPR insulation, PCP sheath, and Center Extensible Pilot ensures that the cable is resistant to electrical faults, mechanical damage, and environmental hazards.

This makes it a safe and reliable choice for powering critical equipment in potentially hazardous underground environments.

The Type 409 Mining Trailing Cable is designed for a variety of applications within the mining industry, particularly in underground operations.

Powering Draglines

Draglines are among the most powerful and essential pieces of equipment in mining operations. They require a reliable power source to perform heavy lifting and excavation tasks. The Type 409 Cable, with its high voltage capacity and robust construction, is ideal for powering draglines, ensuring they operate efficiently and without interruption.

Shovels and Drills

In underground mining, shovels and drills are critical for material extraction and site preparation. The Type 409 Cable provides the necessary power to keep these machines running at optimal performance levels. Its durability and flexibility make it easy to deploy in tight spaces and complex underground environments.

Underground Mining Operations

Whether it’s powering machinery, providing lighting, or supporting ventilation systems, the Type 409 Cable is versatile enough to meet the diverse needs of underground mining operations. Its ability to withstand harsh conditions and maintain reliable performance makes it an invaluable asset in any mining project.

Feeder Cables and Power Distribution

The Type 409 Cable is also well-suited for use as feeder cables in underground mining, where it can efficiently distribute power from the main source to various parts of the operation. This ensures that all equipment receives the power it needs to function effectively, reducing the risk of downtime and improving overall productivity.

The combination of EPR insulation, PCP sheath, and Center Extensible Pilot in the Type 409 Mining Trailing Cable is what sets it apart from other cables. Let’s take a closer look at the benefits of these materials:

EPR Insulation

EPR is an advanced insulation material known for its excellent dielectric properties and resistance to heat, moisture, and chemicals. It provides superior electrical insulation, preventing short circuits and ensuring the cable’s longevity. In mining environments, where cables are often exposed to moisture and extreme conditions, EPR insulation offers reliable performance, reducing the risk of electrical failures and enhancing safety.

PCP Sheath

The PCP sheath is designed to protect the cable from external damage, including abrasion, cuts, and exposure to harsh chemicals. PCP is highly durable and flexible, making it ideal for use in underground mining, where cables are subjected to rough handling and demanding conditions. The PCP sheath ensures that the cable remains intact and functional, even in the most challenging environments.

Center Extensible Pilot

The Center Extensible Pilot is a key component that provides the cable with structural stability and controlled flexibility. It prevents the internal components of the cable from being damaged due to mechanical stress or elongation. This is particularly important in mining operations, where cables are constantly moved and bent. The Center Extensible Pilot ensures that the cable maintains its integrity and performance, even after prolonged use.

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 409.1 Class2 | |||||||||||

| 6 | 84/0.30 | 1.5 | 7/0.25 | 7.2 | 24/0.20 | 0.8 | 3.8 | 30.0 | 129 | ||

| 10 | 77/0.40 | 1.5 | 7/0.25 | 8.6 | 24/0.20 | 0.8 | 3.8 | 32.6 | 157 | ||

| 16 | 126/0.40 | 1.6 | 7/0.25 | 9.6 | 24/0.20 | 0.8 | 4.0 | 35.8 | 197 | ||

| 25 | 209/0.40 | 1.6 | 7/0.25 | 11.3 | 24/0.20 | 0.8 | 4.3 | 39.7 | 255 | ||

| 35 | 285/0.40 | 1.6 | 7/0.25 | 12.4 | 24/0.20 | 0.8 | 4.6 | 43.1 | 312 | ||

| 50 | 380/0.40 | 1.7 | 7/0.25 | 14.1 | 40/0.20 | 0.8 | 5.0 | 47.7 | 386 | ||

| 70 | 203/0.67 | 1.8 | 7/0.25 | 16.5 | 40/0.20 | 0.8 | 5.4 | 53.9 | 503 | ||

| 95 | 259/0.67 | 2.0 | 7/0.30 | 21.8 | 40/0.20 | 0.8 | 6.0 | 59.3 | 622 | ||

| 120 | 336/0.67 | 2.1 | 7/0.30 | 24.7 | 40/0.20 | 0.8 | 6.4 | 65.1 | 760 | ||

| 150 | 427/0.67 | 2.3 | 7/0.40 | 36.1 | 40/0.20 | 0.8 | 6.9 | 72.1 | 960 | ||

| 185 | 518/0.67 | 2.5 | 7/0.40 | 40.5 | 40/0.20 | 0.8 | 7.4 | 78.6 | 1160 | ||

| 240 | 672/0.67 | 2.8 | 7/0.50 | 57.7 | 40/0.20 | 0.8 | 8.2 | 88.6 | 1490 | ||

| 300 | 854/0.67 | 3.0 | 7/0.50 | 63.2 | 40/0.20 | 0.8 | 8.8 | 96.3 | 1800 | ||

| Type 409.3 Class2 | |||||||||||

| 16 | 126/0.40 | 3.0 | 7/0.25 | 13.1 | 24/0.20 | 0.8 | 5.3 | 46.2 | 301 | ||

| 25 | 209/0.40 | 3.0 | 7/0.25 | 14.8 | 24/0.20 | 0.8 | 5.6 | 50.1 | 371 | ||

In conclusion, the Type 409 Mining Trailing Cable is a superior choice for underground mining operations, offering unmatched durability, flexibility, and reliability.

With its EPR insulation, PCP sheath, and Center Extensible Pilot, this cable is engineered to handle the unique challenges of underground mining, providing consistent power to critical equipment such as draglines, shovels, and drills.

For mining operations looking to enhance efficiency, reduce downtime, and improve safety, the Type 409 Cable is the ultimate solution. Its ability to withstand high voltages, mechanical stress, and harsh environmental conditions makes it an invaluable asset in any mining project.

By choosing the Type 409 Mining Trailing Cable, you’re investing in a product that is designed to meet the rigorous demands of the mining industry—providing strength, flexibility, and peace of mind where it’s needed most.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.