Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Packaging Details: Cable Reels or Packaging Bags

Payment Terms: T/T, Western Union

Flexible Handling: |

Easy Handling In Dynamic Conditions |

Material: |

Special Compounds |

Custom Power Solutions: |

Tailored For Equipment Needs |

Grounding Features: |

Includes Grounding For Added Safety |

Temperature Resilience: |

Thrives In Extreme Temperatures |

High Current Capability: |

Efficient High-current Transmission |

Armoring Material: |

Galvanized Steel Wires |

Armor Type: |

Galvanized Steel Interlocked Armor |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Highly Reliable: |

Trustworthy In Critical Tasks |

Flexible Handling: |

Easy Handling In Dynamic Conditions |

Material: |

Special Compounds |

Custom Power Solutions: |

Tailored For Equipment Needs |

Grounding Features: |

Includes Grounding For Added Safety |

Temperature Resilience: |

Thrives In Extreme Temperatures |

High Current Capability: |

Efficient High-current Transmission |

Armoring Material: |

Galvanized Steel Wires |

Armor Type: |

Galvanized Steel Interlocked Armor |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Highly Reliable: |

Trustworthy In Critical Tasks |

In the mining industry, the importance of durable and reliable cables cannot be overstated. The Type 440 Mining Cable series is specifically designed to meet the rigorous demands of mining operations, offering various types that cater to different voltage levels and application scenarios.

These cables are engineered to withstand the harsh conditions often found in mining environments, providing the necessary power and safety required for efficient operation.

This article will delve into the Type 440 Mining Cable and its different variants—Type 440.1 (Class 2), Type 440.3 (Class 2), Type 440.6 (Class 2), Type 440.11 (Class 2), and Type 440.22 (Class 2).

We will explore their unique functions, applicable scenarios, and the manufacturing processes that make them stand out in the industry.

The Type 440 Mining Cable series is known for its robust construction, which includes high-quality insulation and sheathing materials.

These cables are designed to deliver reliable performance in the most demanding environments, such as open-pit mines, underground operations, and heavy industrial settings.

Durability:

Engineered to withstand mechanical stress, abrasion, and exposure to harsh chemicals.

Safety:

Compliance with industry standards ensures safe operation in hazardous environments.

Flexibility:

Designed for ease of installation, even in tight or complex spaces.

Each variant within the Type 440 Mining Cable series is tailored to specific voltage levels and applications.

Below, we’ll explore the differences between these types and how they are best utilized in mining operations.

Type 440.1 (Class 2) is designed for low voltage applications, typically ranging from 1.1kV to 3.3kV.

This variant is ideal for powering smaller equipment and systems within mining operations, where precise control and reliable performance are essential.

Type 440.1 is often used in scenarios such as powering pumps, lighting systems, and small machinery that require consistent, low-voltage power.

The manufacturing process of Type 440.1 involves the use of high-quality insulation materials that are resistant to heat and moisture, ensuring longevity and reliability even in harsh underground environments.

Type 440.3 (Class 2) is engineered for medium voltage applications, ranging from 3.3kV to 6.6kV.

This cable is ideal for more demanding tasks, such as powering conveyor systems, drilling rigs, and other medium-duty mining equipment.

The Type 440.3 variant features enhanced insulation and a tougher sheath, designed to resist mechanical wear and tear.

This makes it an excellent choice for environments where the cable may be exposed to abrasion, sharp edges, or heavy machinery.

For high voltage applications, Type 440.6 (Class 2) is the go-to option. This variant supports voltage levels from 6.6kV to 11kV, making it suitable for heavy-duty equipment such as draglines, shovels, and large-scale pumps.

The Type 440.6 variant is manufactured with additional layers of insulation and shielding to prevent electrical interference and ensure safe operation at higher voltages.

The cable’s construction also includes a reinforced sheath, providing added protection against mechanical damage and harsh environmental conditions.

Type 440.11 (Class 2) is designed for very high voltage applications, ranging from 11kV to 22kV. This cable is built to handle the extreme demands of large-scale mining operations and is often used to power high-capacity draglines, longwall systems, and other heavy machinery.

The manufacturing process of Type 440.11 involves advanced materials and techniques to ensure that the cable can withstand extreme electrical stress, mechanical impact, and environmental challenges.

This includes a multi-layer insulation system that provides exceptional resistance to voltage spikes and surges, ensuring the cable’s longevity and reliability in the most demanding settings.

At the top of the range is Type 440.22 (Class 2), designed for ultra-high voltage applications up to 33kV.

This variant is used in the most specialized and demanding mining scenarios, where the highest levels of power and reliability are required.

Type 440.22 is constructed with the latest advancements in insulation and sheathing technology, ensuring that it can operate safely at ultra-high voltages without compromising on performance or safety.

This makes it the ideal choice for critical infrastructure within mining operations, such as main power supply lines and high-capacity machinery.

The Type 440 Mining Cable series is manufactured using state-of-the-art processes that ensure each variant meets the highest standards of quality and performance. These processes include:

Advanced Insulation Techniques:

Each cable variant is insulated using materials that are carefully selected for their electrical and mechanical properties. The insulation process is designed to ensure consistent performance across different voltage levels and environmental conditions.

Precision Sheathing:

The outer sheath of each cable is applied using precision techniques that provide optimal protection against environmental hazards, mechanical stress, and chemical exposure. This sheathing process is tailored to the specific needs of each variant, ensuring that the cable can withstand the conditions it will face in the field.

Rigorous Testing:

Before they reach the market, all Type 440 Mining Cables undergo rigorous testing to ensure they meet or exceed industry standards. This includes tests for voltage handling, insulation resistance, flexibility, and durability.

Selecting the right Type 440 Mining Cable depends on the specific requirements of your mining operation. Here are some scenarios to consider:

For low voltage equipment and small-scale operations, Type 440.1 (Class 2) offers the ideal balance of performance and cost-effectiveness.

For medium voltage tasks such as conveyor systems and drilling rigs, Type 440.3 (Class 2) provides enhanced durability and reliable power delivery.

For high voltage applications involving heavy-duty machinery, Type 440.6 (Class 2) ensures maximum efficiency and safety.

For very high voltage scenarios requiring the utmost in reliability, Type 440.11 (Class 2) offers advanced protection and performance.

For ultra-high voltage and specialized applications, Type 440.22 (Class 2) delivers the ultimate in power and durability.

- UNDERGROUND AND SURFACE MINING OPERATIONS

- MATERIAL HANDLING EQUIPMENT

- CONVEYOR SYSTEMS

- DRILLING AND EXCAVATION MACHINERY

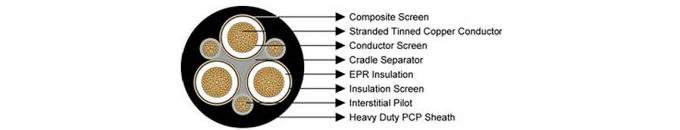

These cables are mainly used as flexible feedertrailing cables for power supply to machinery and equipment, include 3 large pilots and a centralsemiconductive cradle for support and protection of power cores.

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 440.1 Class2 | |||||||||||

| 6 | 84/0.30 | 1.5 | 7/0.25 | 7.2 | 18/0.30 | 1.0 | 3.8 | 30.0 | 135 | ||

| 10 | 77/0.40 | 1.5 | 7/0.25 | 8.6 | 27/0.30 | 1.0 | 3.8 | 32.6 | 166 | ||

| 16 | 126/0.40 | 1.6 | 7/0.25 | 9.6 | 42/0.30 | 1.0 | 4.0 | 35.8 | 204 | ||

| 25 | 209/0.40 | 1.6 | 7/0.25 | 11.3 | 66/0.30 | 1.2 | 4.3 | 39.7 | 269 | ||

| 35 | 285/0.40 | 1.6 | 7/0.25 | 12.4 | 90/0.30 | 1.2 | 4.6 | 43.1 | 324 | ||

| 50 | 380/0.40 | 1.7 | 7/0.25 | 14.1 | 120/0.30 | 1.2 | 5.0 | 47.7 | 403 | ||

| 70 | 203/0.67 | 1.8 | 7/0.25 | 16.5 | 39/0.67 | 1.2 | 5.4 | 53.9 | 539 | ||

| 95 | 259/0.67 | 2.0 | 7/0.30 | 21.8 | 39/0.67 | 1.2 | 6.0 | 59.3 | 659 | ||

| 120 | 336/0.67 | 2.1 | 7/0.30 | 24.7 | 42/0.67 | 1.4 | 6.4 | 65.1 | 802 | ||

| 150 | 427/0.67 | 2.3 | 7/0.40 | 36.1 | 54/0.67 | 1.4 | 6.9 | 72.1 | 1018 | ||

| 185 | 518/0.67 | 2.5 | 7/0.40 | 40.5 | 63/0.67 | 1.4 | 7.4 | 78.6 | 1198 | ||

| 240 | 672/0.67 | 2.8 | 7/0.50 | 57.7 | 77/0.67 | 1.6 | 8.2 | 88.6 | 1549 | ||

| 300 | 854/0.67 | 3.0 | 7/0.50 | 63.2 | 98/0.67 | 1.6 | 8.8 | 96.3 | 1870 | ||

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 440.3 Class2 | |||||||||||

| 16 | 126/0.40 | 3.0 | 7/0.25 | 13.1 | 42/0.30 | 1.4 | 5.3 | 46.2 | 304 | ||

| 25 | 209/0.40 | 3.0 | 7/0.25 | 14.8 | 66/0.30 | 1.4 | 5.6 | 50.1 | 379 | ||

| 35 | 285/0.40 | 3.0 | 7/0.25 | 15.8 | 90/0.30 | 1.4 | 5.9 | 53.5 | 446 | ||

| 50 | 380/0.40 | 3.0 | 7/0.25 | 17.2 | 120/0.30 | 1.4 | 6.3 | 57.6 | 524 | ||

| 70 | 203/0.67 | 3.0 | 7/0.25 | 18.6 | 39/0.67 | 1.4 | 6.6 | 62.5 | 659 | ||

| 95 | 259/0.67 | 3.0 | 7/0.25 | 20.3 | 39/0.67 | 1.6 | 7.1 | 66.2 | 754 | ||

| 120 | 336/0.67 | 3.0 | 7/0.30 | 27.2 | 42/0.67 | 1.6 | 7.4 | 72.0 | 914 | ||

| 150 | 427/0.67 | 3.0 | 7/0.40 | 39.6 | 54/0.67 | 1.6 | 7.8 | 78.0 | 1119 | ||

| 185 | 518/0.67 | 3.0 | 7/0.40 | 42.2 | 63/0.67 | 1.6 | 8.2 | 83.4 | 1289 | ||

| 240 | 672/0.67 | 3.0 | 7/0.40 | 46.6 | 77/0.67 | 1.6 | 8.8 | 90.3 | 1559 | ||

| 300 | 854/0.67 | 3.0 | 7/0.50 | 63.2 | 98/0.67 | 1.6 | 9.4 | 98.4 | 1920 | ||

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 440.6 Class2 | |||||||||||

| 16 | 126/0.40 | 5.0 | 7/0.25 | 17.2 | 42/0.30 | 1.4 | 6.4 | 57.3 | 444 | ||

| 25 | 209/0.40 | 5.0 | 7/0.25 | 18.6 | 66/0.30 | 1.6 | 6.7 | 61.2 | 523 | ||

| 35 | 285/0.40 | 5.0 | 7/0.25 | 18.6 | 90/0.30 | 1.6 | 7.0 | 64.6 | 599 | ||

| 50 | 380/0.40 | 5.0 | 7/0.25 | 21.3 | 120/0.30 | 1.6 | 7.3 | 68.5 | 689 | ||

| 70 | 203/0.67 | 5.0 | 7/0.25 | 23.4 | 39/0.67 | 1.6 | 7.7 | 73.7 | 834 | ||

| 95 | 259/0.67 | 5.0 | 7/0.30 | 29.2 | 39/0.67 | 1.8 | 8.1 | 77.8 | 964 | ||

| 120 | 336/0.67 | 5.0 | 7/0.30 | 31.7 | 42/0.67 | 1.8 | 8.5 | 83.1 | 1119 | ||

| 150 | 427/0.67 | 5.0 | 7/0.40 | 45.7 | 54/0.67 | 1.8 | 8.9 | 89.1 | 1349 | ||

| 185 | 518/0.67 | 5.0 | 7/0.40 | 48.4 | 63/0.67 | 1.8 | 9.3 | 94.5 | 1529 | ||

| 240 | 672/0.67 | 5.0 | 7/0.40 | 52.8 | 77/0.67 | 1.8 | 9.9 | 101.4 | 1810 | ||

| 300 | 854/0.67 | 5.0 | 7/0.50 | 71.5 | 98/0.67 | 1.8 | 10.4 | 109.3 | 2190 | ||

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 440.11 Class2 | |||||||||||

| 25 | 209/0.40 | 7.6 | 7/0.25 | 23.7 | 66/0.30 | 2.0 | 8.1 | 75.6 | 759 | ||

| 35 | 285/0.40 | 7.6 | 7/0.30 | 30.2 | 90/0.30 | 2.0 | 8.4 | 79.7 | 869 | ||

| 50 | 380/0.40 | 7.6 | 7/0.30 | 31.7 | 120/0.30 | 2.0 | 8.7 | 83.6 | 974 | ||

| 70 | 203/0.67 | 7.6 | 7/0.30 | 34.1 | 39/0.67 | 2.0 | 9.1 | 88.8 | 1139 | ||

| 95 | 259/0.67 | 7.6 | 7/0.40 | 47.5 | 39/0.67 | 2.2 | 9.6 | 93.7 | 1319 | ||

| 120 | 336/0.67 | 7.6 | 7/0.40 | 51.0 | 42/0.67 | 2.2 | 9.9 | 98.8 | 1489 | ||

| 150 | 427/0.67 | 7.6 | 7/0.40 | 53.7 | 54/0.67 | 2.2 | 10.3 | 103.5 | 1679 | ||

| 185 | 518/0.67 | 7.6 | 7/0.40 | 57.2 | 63/0.67 | 2.2 | 10.7 | 108.8 | 1880 | ||

| NOMINAL CONDUCTOR AREA | STRAND SIZE | INSULATION THICKNESS | CORE SCREEN | PILOT CONDUCTOR | THICKNESS OF SHEATH | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | ||||

| STRAND SIZE | AREA OF SCREEN | STRAND SIZE | THICKNESS OF COVERING | ||||||||

| MM² | NO/MM | MM | NO/MM | MM² | NO/MM | MM | MM | MM | KG/100M | ||

| Type 440.22 Class2 | |||||||||||

| 35 | 285/0.40 | 10.5 | 7/0.40 | 53.2 | 90/0.30 | 2.5 | 10.0 | 105.0 | 1270 | ||

| 50 | 380/0.40 | 10.5 | 7/0.40 | 54.1 | 120/0.30 | 2.5 | 10.3 | 108.9 | 1392 | ||

| 70 | 203/0.67 | 10.5 | 7/0.40 | 58.0 | 39/0.67 | 2.5 | 10.7 | 111.2 | 1558 | ||

The Type 440 Mining Cable series is more than just a product; it’s a commitment to powering the future of mining. With its range of variants designed to meet different voltage levels and application scenarios, the Type 440 series provides the versatility, durability, and reliability that mining operations demand.

Whether you’re powering small machinery or driving high-capacity systems, there’s a Type 440 Mining Cable that’s perfect for your needs. By choosing the right variant for your operation, you can ensure safe, efficient, and reliable performance, no matter how challenging the environment.

Invest in the Type 440 Mining Cable series and experience the difference that quality, innovation, and expertise can make in your mining operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.