Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Type F-(N)TSCGEWÖU 3.6/6kV To 18/30kV Mining Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Work Day

Payment Terms: T/T, Western Union

Supply Ability: 6,000 meters per week

Material: |

Copper |

Flexible Mobility: |

High Flexibility For Dynamic Operations |

Type: |

Flexible |

Robust Construction: |

Durable Design For Harsh Environments |

Insulation: |

Special Material |

Reliable Performance: |

Ensures A Long Operational Life |

Material: |

Copper |

Flexible Mobility: |

High Flexibility For Dynamic Operations |

Type: |

Flexible |

Robust Construction: |

Durable Design For Harsh Environments |

Insulation: |

Special Material |

Reliable Performance: |

Ensures A Long Operational Life |

In the dynamic world of mining, where efficiency and reliability are paramount, the right equipment can make all the difference. This is especially true when it comes to the power supply that drives your operations.

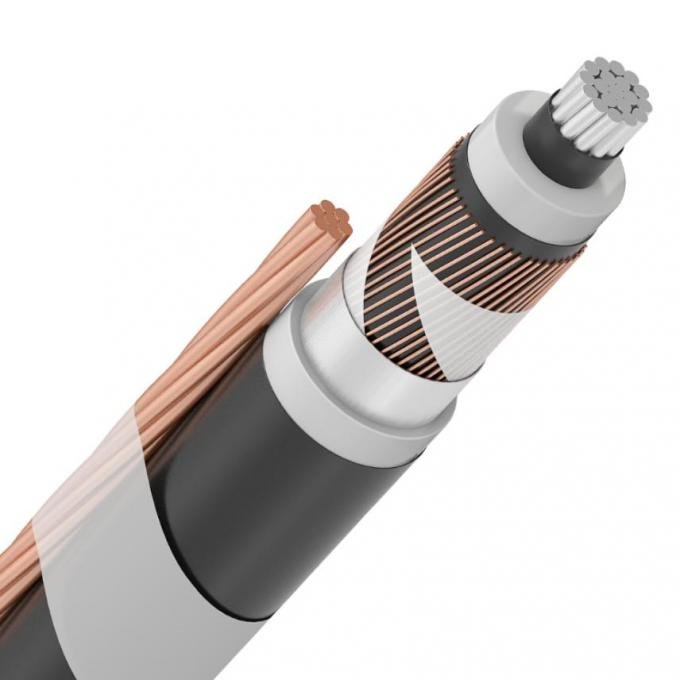

The Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable is designed to meet the rigorous demands of supplying power to mining excavating and crushing machines, as well as other critical mining equipment.

Crafted with precision and adhering to the stringent German VDE standards, this cable is not just a product—it's a promise of durability, safet, and performance in the most challenging mining environments.

This Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable is engineered to provide reliable power in some of the harshest conditions imaginable.

Mining environments are notorious for their demanding conditions, from extreme temperatures to rough terrain, and the constant threat of mechanical damage. This cable is designed specifically to withstand these challenges, ensuring that your mining operations remain uninterrupted.

But what does the model name Type F-(N)TSCGEWÖU actually mean? Understanding this can give you a better appreciation of the cable’s capabilities:

F: The letter "F" in the cable model stands for Flexible, highlighting the cable’s ability to bend and flex without losing integrity, which is crucial in mining environments where cables are often subject to movement and mechanical stress.

(N): Denotes Normal application, meaning this cable is suitable for standard, everyday use in mining operations.

TSC: Refers to the Tinned Copper Stranded Conductors, which offer excellent conductivity and corrosion resistance, essential for maintaining consistent power delivery even in moist or corrosive conditions.

GEW: Indicates that the cable is designed with Grounded Earth Wires for safety, reducing the risk of electrical shocks or short circuits.

ÖU: This specifies the Outer Sheath material, which is resistant to oil, chemicals, and UV radiation, ensuring the cable remains durable even in harsh outdoor conditions.

The Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable isn’t just any cable; it’s designed and produced in strict accordance with the VDE Standard. But what exactly is the VDE Standard, and why should it matter to you?

VDE stands for Verband der Elektrotechnik, Elektronik und Informationstechnik, a highly respected German association known for its rigorous testing and certification processes.

VDE certification is a mark of quality, safety, and reliability, ensuring that the products meet the highest standards for electrical engineering.

Safety: VDE-certified cables are designed to minimize risks, ensuring that they are safe for use in even the most hazardous environments.

Quality: These cables undergo stringent testing to ensure they can withstand the stresses of mining operations, from mechanical wear and tear to extreme environmental conditions.

Compliance: Using a VDE-certified cable like the Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable ensures that your operations comply with international standards, which is particularly important for multinational companies.

When selecting the right cable for your mining operations, it’s crucial to consider the specific environmental conditions in which the cable will be used. The Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable is specifically designed to excel in the following environments:

Pilbara, Western Australia:

Known for its iron ore mines, this region presents extreme heat, dust, and a harsh, abrasive environment. The cable’s durable outer sheath and flexible design make it ideal for withstanding these conditions.

Gobi Desert, Mongolia:

With its extreme temperature fluctuations and sandy terrain, the Gobi Desert is a challenging environment for any mining operation. The cable’s robust construction ensures it remains operational despite these challenges.

Copperbelt, Zambia:

The humid, tropical climate of the Copperbelt region, combined with frequent heavy rains, requires a cable that is resistant to moisture and corrosion. The tinned copper conductors of this cable make it an excellent choice.

Siberia, Russia:

Siberia’s freezing temperatures and icy conditions demand a cable that can maintain flexibility and performance in sub-zero temperatures. This cable’s design ensures it can withstand even the coldest environments.

Goldfields, Ghana:

The Goldfields region’s high humidity and frequent storms require a cable that can resist water ingress and mechanical damage, making this cable an ideal solution.

Atacama Desert, Chile:

As one of the driest places on Earth, the Atacama Desert presents unique challenges, including extreme UV radiation and dry, abrasive conditions. The UV-resistant outer sheath of this cable ensures it can withstand the harsh sun and dry environment.

Operating in these diverse and often extreme environments comes with inherent risks. However, the Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable has been specifically designed to mitigate these risks, ensuring that your operations run smoothly and safely.

Mining operations are rough on equipment, and cables are no exception. From being dragged across sharp rocks to being crushed under heavy machinery, the potential for mechanical damage is high.

Solution: The cable’s flexible design and durable outer sheath provide excellent resistance to mechanical wear and tear, ensuring a longer lifespan and reduced downtime due to cable failure.

Many mining environments are either extremely wet or involve corrosive materials that can damage standard cables over time.

Solution: The tinned copper conductors used in this cable offer superior resistance to corrosion, while the robust outer sheath prevents moisture ingress, ensuring reliable power delivery even in the most challenging conditions.

Whether it’s the searing heat of the Australian outback or the freezing cold of Siberia, extreme temperatures can affect the performance and lifespan of a cable.

Solution: This cable is designed to maintain flexibility and performance across a wide temperature range, ensuring it remains operational no matter where your mining operations take you.

In an environment where high-powered equipment is the norm, the risk of electrical faults is ever-present. Exposed or damaged cables can lead to dangerous situations, including electrical fires or shocks.

Solution: The grounded earth wires and high-quality insulation in this cable reduce the risk of electrical faults, ensuring the safety of your workers and equipment.

Understanding that no two mining operations are alike, Feichun Cable offers special upgrades and modifications to the Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable based on the unique characteristics of your local environment.

For example, in regions with high rodent activity, such as parts of Africa and Australia, we can incorporate a special rodent-resistant compound into the cable’s sheath, preventing costly damage caused by gnawing animals.

In extremely cold environments, we can upgrade the cable’s insulation to ensure it remains flexible and functional, even in sub-zero temperatures.

| Number of cores Cross-section | Conductor diameter | Approximate overall diameter | Approximate weight | Conductor resistance at 200C | Current-currying capacity at 300C |

| mm2 | mm | mm | kg/km | Ω/km | A |

| 3.6/6kV F-(N)TSCGEWÖU | |||||

| 3x25+3x25/3 | 6.30 | 40.3 | 2492 | 0.795 | 132 |

| 3x25+3x50/3 | 6.30 | 40.3 | 2613 | 0.795 | 132 |

| 3x35+3x25/3 | 7.00 | 41.8 | 2858 | 0.565 | 161 |

| 3x35+3x50/3 | 7.00 | 41.8 | 2979 | 0.565 | 161 |

| 3x50+3x25/3 | 9.00 | 46.2 | 3557 | 0.393 | 202 |

| 3x50+3x50/3 | 9.00 | 46.2 | 3677 | 0.393 | 202 |

| 3x70+3x35/3 | 10.80 | 51.8 | 4593 | 0.277 | 251 |

| 3x70+3x50/3 | 10.80 | 51.8 | 4714 | 0.277 | 251 |

| 3x95+3x50/3 | 12.90 | 56.4 | 5665 | 0.210 | 301 |

| 3x120+3x70/3 | 14.00 | 58.7 | 6718 | 0.164 | 351 |

| 3x150+3x70/3 | 15.80 | 64.0 | 7968 | 0.132 | 405 |

| 3x185+3x95/3 | 18.10 | 68.0 | 9415 | 0.108 | 462 |

| 3x240+3x120/3 | 19.60 | 72.0 | 11395 | 0.0817 | 540 |

| 3x300+3x150/3 | 23.20 | 82.2 | 14350 | 0.0654 | 620 |

| Number of cores Cross-section | Conductor diameter | Approximate overall diameter | Approximate weight | Conductor resistance at 200C | Current-currying capacity at 300C |

| mm2 | mm | mm | kg/km | Ω/km | A |

| 6/10kV F-(N)TSCGEWÖU | |||||

| 3x25+3x25/3 | 6.30 | 42.0 | 2649 | 0.795 | 132 |

| 3x25+3x50/3 | 6.30 | 42.0 | 2769 | 0.795 | 132 |

| 3x35+3x25/3 | 7.00 | 43.6 | 3021 | 0.565 | 161 |

| 3x35+3x50/3 | 7.00 | 43.6 | 3141 | 0.565 | 161 |

| 3x50+3x25/3 | 9.00 | 47.9 | 3735 | 0.393 | 202 |

| 3x50+3x50/3 | 9.00 | 47.9 | 3856 | 0.393 | 202 |

| 3x70+3x35/3 | 10.80 | 53.6 | 4794 | 0.277 | 251 |

| 3x70+3x50/3 | 10.80 | 53.6 | 4914 | 0.277 | 251 |

| 3x95+3x50/3 | 12.90 | 58.1 | 5882 | 0.210 | 301 |

| 3x120+3x70/3 | 14.00 | 60.4 | 6944 | 0.164 | 351 |

| 3x150+3x70/3 | 15.80 | 66.2 | 8342 | 0.132 | 405 |

| 3x185+3x95/3 | 18.10 | 71.0 | 9873 | 0.108 | 462 |

| 3x240+3x120/3 | 19.60 | 76.0 | 11989 | 0.0817 | 540 |

| 3x300+3x150/3 | 23.20 | 83.9 | 14665 | 0.0654 | 620 |

| Number of cores Cross-section | Conductor diameter | Approximate overall diameter | Approximate weight | Conductor resistance at 200C | Current-currying capacity at 300C |

| mm2 | mm | mm | kg/km | Ω/km | A |

| 8.7/15kV F-(N)TSCGEWÖU | |||||

| 3x25+3x25/3 | 6.30 | 45.4 | 2981 | 0.795 | 138 |

| 3x25+3x50/3 | 6.30 | 45.4 | 3101 | 0.795 | 138 |

| 3x35+3x25/3 | 7.00 | 47.0 | 3365 | 0.565 | 173 |

| 3x35+3x50/3 | 7.00 | 47.0 | 3485 | 0.565 | 173 |

| 3x50+3x25/3 | 9.00 | 53.1 | 4330 | 0.393 | 216 |

| 3x50+3x50/3 | 9.00 | 53.1 | 4450 | 0.393 | 216 |

| 3x70+3x35/3 | 10.80 | 57.0 | 5214 | 0.277 | 265 |

| 3x70+3x50/3 | 10.80 | 57.0 | 5335 | 0.277 | 265 |

| 3x95+3x50/3 | 12.90 | 63.3 | 6597 | 0.210 | 320 |

| 3x120+3x70/3 | 14.00 | 67.1 | 7919 | 0.164 | 370 |

| 3x150+3x70/3 | 15.80 | 69.7 | 8859 | 0.132 | 428 |

| 3x240+3x120/3 | 19.60 | 79.5 | 12581 | 0.0817 | 574 |

| 3x300+3x150/3 | 23.20 | 89.2 | 15684 | 0.0654 | 665 |

| Number of cores Cross-section | Conductor diameter | Approximate overall diameter | Approximate weight | Conductor resistance at 200C | Current-currying capacity at 300C |

| mm2 | mm | mm | kg/km | Ω/km | A |

| 12/20kV F-(N)TSCGEWÖU | |||||

| 3x25+3x25/3 | 6.30 | 48.5 | 3294 | 0.795 | 138 |

| 3x25+3x50/3 | 6.30 | 48.5 | 3414 | 0.795 | 138 |

| 3x35+3x25/3 | 7.00 | 51.8 | 3900 | 0.565 | 173 |

| 3x35+3x50/3 | 7.00 | 51.8 | 4021 | 0.565 | 173 |

| 3x50+3x25/3 | 9.00 | 56.1 | 4693 | 0.393 | 216 |

| 3x50+3x50/3 | 9.00 | 56.1 | 4814 | 0.393 | 216 |

| 3x70+3x35/3 | 10.80 | 60.0 | 5604 | 0.277 | 265 |

| 3x70+3x50/3 | 10.80 | 60.0 | 5724 | 0.277 | 265 |

| 3x95+3x50/3 | 12.90 | 66.3 | 7029 | 0.210 | 320 |

| 3x120+3x70/3 | 14.00 | 70.1 | 8377 | 0.164 | 370 |

| 3x150+3x70/3 | 15.80 | 72.7 | 9332 | 0.132 | 428 |

| 3x185+3x95/3 | 18.10 | 79.3 | 11258 | 0.108 | 489 |

| 3x240+3x120/3 | 19.60 | 82.5 | 13120 | 0.0817 | 574 |

| 3x300+3x150/3 | 23.20 | 92.2 | 16288 | 0.0654 | 665 |

| Number of cores Cross-section | Conductor diameter | Approximate overall diameter | Approximate weight | Conductor resistance at 200C | Current-currying capacity at 300C |

| mm2 | mm | mm | kg/km | Ω/km | A |

| 18/30kV F-(N)TSCGEWÖU | |||||

| 3x25+3x25/3 | 6.30 | 58.0 | 4426 | 0.795 | 138 |

| 3x25+3x50/3 | 6.30 | 58.0 | 4546 | 0.795 | 138 |

| 3x35+3x25/3 | 7.00 | 59.6 | 4853 | 0.565 | 173 |

| 3x35+3x50/3 | 7.00 | 59.6 | 4974 | 0.565 | 173 |

| 3x50+3x25/3 | 9.00 | 65.7 | 5990 | 0.393 | 216 |

| 3x50+3x50/3 | 9.00 | 65.7 | 6110 | 0.393 | 216 |

| 3x70+3x35/3 | 10.80 | 69.6 | 6982 | 0.277 | 265 |

| 3x70+3x50/3 | 10.80 | 69.6 | 7103 | 0.277 | 265 |

| 3x95+3x50/6 | 12.90 | 75.9 | 8543 | 0.210 | 320 |

| 3x120+3x70/3 | 14.00 | 78.2 | 9695 | 0.164 | 370 |

| 3x150+3x70/3 | 15.80 | 82.2 | 10981 | 0.132 | 428 |

| 3x185+3x95/3 | 18.10 | 88.8 | 13046 | 0.108 | 489 |

| 3x240+3x120/3 | 19.60 | 92.0 | 14977 | 0.0817 | 574 |

| Size | Nominal insulation thickness | Nominal jacket thickness | Approximate overall diameter | Approximate weight | Current rating at 300C in air |

| mm2 | mm | mm | mm | kg/km | A |

| NTMCGEWÖU 3.6/6 kV | |||||

| 1x16/16 | 3.4 | 2.20 | 20.3 | 720 | 141 |

| 1x25/16 | 3.4 | 2.20 | 21.5 | 828 | 187 |

| 1x35/16 | 3.4 | 2.20 | 22.2 | 933 | 231 |

| 1x50/16 | 3.4 | 2.20 | 24.2 | 1119 | 288 |

| 1x70/16 | 3.4 | 2.50 | 26.6 | 1384 | 357 |

| 1x95/16 | 3.4 | 2.50 | 28.7 | 1637 | 430 |

| 1x120/16 | 3.4 | 2.50 | 29.8 | 1888 | 503 |

| 1x150/25 | 3.4 | 3.00 | 32.7 | 2382 | 577 |

| 1x185/25 | 3.4 | 3.00 | 34.9 | 2725 | 658 |

| NTMCGEWÖU 6/10 kV | |||||

| 1x16/16 | 3.4 | 2.2 | 21.1 | 755 | 141 |

| 1x25/16 | 3.4 | 2.2 | 22.3 | 864 | 187 |

| 1x35/16 | 3.4 | 2.2 | 23.0 | 970 | 231 |

| 1x50/16 | 3.4 | 2.5 | 25.6 | 1197 | 289 |

| 1x70/16 | 3.4 | 2.5 | 27.4 | 1429 | 356 |

| 1x95/16 | 3.4 | 2.5 | 29.5 | 1686 | 430 |

| 1x120/16 | 3.4 | 3.0 | 31.6 | 2016 | 503 |

| 1x150/25 | 3.4 | 3.0 | 33.5 | 2438 | 577 |

| 1x185/25 | 3.4 | 3.5 | 35.7 | 2785 | 658 |

| NTMCGEWÖU 12/20 kV | |||||

| 1x16/16 | 5.5 | 2.50 | 25.9 | 994 | 150 |

| 1x25/16 | 5.5 | 2.50 | 27.1 | 1116 | 198 |

| 1x35/16 | 5.5 | 2.50 | 27.8 | 1230 | 245 |

| 1x50/16 | 5.5 | 2.50 | 29.8 | 1440 | 307 |

| 1x70/16 | 5.5 | 3.00 | 32.6 | 1767 | 379 |

| 1x95/16 | 5.5 | 3.00 | 34.7 | 2048 | 456 |

| 1x120/16 | 5.5 | 3.00 | 35.8 | 2312 | 531 |

| 1x150/25 | 5.5 | 3.50 | 38.7 | 2846 | 611 |

| 1x185/25 | 5.5 | 3.50 | 40.9 | 3218 | 698 |

| NTMCGEWÖU 18/30 kV | |||||

| 1x16/16 | 8.0 | 3.00 | 31.9 | 1368 | 150 |

| 1x25/16 | 8.0 | 3.00 | 33.1 | 1505 | 198 |

| 1x35/16 | 8.0 | 3.00 | 33.8 | 1629 | 245 |

| 1x50/16 | 8.0 | 3.00 | 35.8 | 1866 | 307 |

| 1x70/16 | 8.0 | 3.50 | 38.6 | 2230 | 379 |

| 1x95/16 | 8.0 | 3.50 | 40.7 | 2539 | 456 |

| 1x120/16 | 8.0 | 3.50 | 41.8 | 2818 | 531 |

| 1x150/25 | 8.0 | 3.50 | 43.7 | 3284 | 611 |

| 1x185/25 | 8.0 | 3.50 | 45.9 | 3680 | 698 |

At the heart of Feichun Cable’s success is its state-of-the-art production base located in Hefei, Anhui—the science and technology capital of China.

This region is not only a global manufacturing hub but also home to some of the world’s leading research institutions, including the University of Science and Technology of China (USTC).

Feichun Cable’s collaboration with USTC is a key factor in our ability to stay at the forefront of the cable manufacturing industry. Through funding and donations, we have established a high-level laboratory dedicated to the research and development of advanced polymer materials.

This partnership ensures that Feichun Cable is always equipped with the latest innovations in material science, allowing us to produce cables that meet the most stringent international standards.

Our high-tech R&D and production base in Hefei is equipped with the latest automation technologies, ensuring that every cable we produce meets our exacting standards for quality and performance.

By leveraging the scale advantages of China’s manufacturing industry, we are able to offer our customers high-quality cables at competitive prices.

When you choose Feichun Cable, you’re not just buying a product—you’re investing in a solution that’s backed by cutting-edge research, rigorous testing, and a commitment to quality. We understand the challenges you face in your mining operations, and we’re here to help you overcome them with cables that are designed to last.

Global Expertise: With a production base in China and a global customer base, Feichun Cable understands the unique challenges of mining operations around the world.

Innovation-Driven: Our collaboration with USTC ensures that we are always at the forefront of cable technology, offering our customers the latest advancements in materials and design.

Quality Assurance: Our cables are designed and manufactured in accordance with the most stringent international standards. Every cable undergoes rigorous testing to ensure it can withstand the toughest conditions.

When it comes to powering your mining operations, you can't afford to compromise on quality or reliability. The Type F-(N)TSCGEWÖU 3.6/6 KV Mining Cable from Feichun Cable is more than just a product; it's a solution designed to meet the unique challenges of mining environments around the globe.

With Feichun Cable, you’re choosing a partner dedicated to innovation, quality, and customer satisfaction. Whether you’re operating in the harsh climates of the Gobi Desert or the frigid temperatures of Siberia, Feichun Cable’s products are designed to keep your operations running smoothly and efficiently.

By combining cutting-edge research with top-notch manufacturing, Feichun Cable is proud to offer cables that are built to last and designed to excel in the most demanding environments. Choose Feichun Cable for your mining operations and experience the difference that comes with reliable, high-performance power solutions.

Feichun Cable— powering the future of mining, today.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.