Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

High Voltage Capacity: |

Voltage Resilience For Mining |

Oil Resistant: |

Yes |

Temperature Rating: |

-40°C To +90°C |

Armoring Material: |

Galvanized Steel Wires |

Custom Power Solutions: |

Tailored For Equipment Needs |

Abrasion Resistant: |

Yes |

Standard: |

IEC 60502-1 |

Weight: |

1.2 Lbs/ft |

Outer Sheath Color: |

Black |

Flexibility: |

Extra Flexible |

High Voltage Capacity: |

Voltage Resilience For Mining |

Oil Resistant: |

Yes |

Temperature Rating: |

-40°C To +90°C |

Armoring Material: |

Galvanized Steel Wires |

Custom Power Solutions: |

Tailored For Equipment Needs |

Abrasion Resistant: |

Yes |

Standard: |

IEC 60502-1 |

Weight: |

1.2 Lbs/ft |

Outer Sheath Color: |

Black |

Flexibility: |

Extra Flexible |

In the world of mining, wharf cranes, and materials handling, the reliability of your equipment is paramount. Every piece of machinery plays a critical role in ensuring operations run smoothly and efficiently, and that includes the cables that power them.

Among these, the Type 451 Mining Trailing Cable is a standout performer, offering improved performance in reeling applications and excelling in demanding environments like wharf cranes and materials handling.

This article will explore the unique features of the Type 451 Mining Trailing Cable, highlight its superior performance, and compare it to the Type 441 cable to help you understand why this cable is an excellent choice for your operations.

Trailing cables are vital components in mining and industrial operations, serving as the power lifeline for various types of mobile equipment.

Whether it's heavy machinery in a mine or cranes on a wharf, these cables must endure harsh conditions, including constant movement, mechanical stress, and exposure to environmental elements.

Choosing the right trailing cable can significantly impact the efficiency, safety, and longevity of your equipment.

This is where the Type 451 Mining Trailing Cable comes into play, offering a robust solution tailored to meet the rigorous demands of reeling applications, wharf cranes, and materials handling.

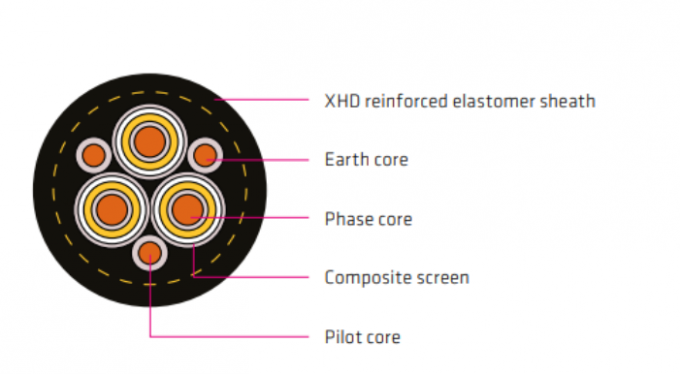

The Type 451 Mining Trailing Cable is engineered to provide maximum performance in environments that require continuous reeling and heavy-duty use.

It is specifically designed to address the challenges associated with the constant winding and unwinding in reeling applications, making it a reliable choice for industries where cable durability and flexibility are non-negotiable.

One of the standout features of the Type 451 cable is its enhanced reeling capabilities.

The cable is constructed with materials that allow it to withstand the repetitive stress of winding and unwinding, reducing the risk of wear and tear. This is especially important in applications like wharf cranes, where the cable must reel in and out continuously, often over long distances.

Flexibility and strength are crucial for trailing cables used in reeling applications.

The Type 451 cable offers a superior blend of both, ensuring that it can bend and flex without compromising its structural integrity.

This feature is particularly beneficial in materials handling operations, where the cable needs to navigate tight spaces and complex pathways.

The Type 451 cable is built to endure the harsh conditions typical of mining and industrial environments.

It features a rugged outer sheath that provides excellent protection against abrasion, mechanical damage, and environmental factors such as moisture, heat, and chemicals.

This durability ensures that the cable can maintain its performance even in the most challenging settings.

In addition to its physical robustness, the Type 451 Mining Trailing Cable delivers outstanding electrical performance.

It is designed to carry high voltage loads safely and efficiently, providing reliable power to your equipment. This is critical in applications where consistent and uninterrupted power supply is essential for operational success.

While both the Type 451 and Type 441 cables are designed for use in mining and industrial applications, there are key differences between the two that make the Type 451 a superior choice for specific scenarios.

The Type 441 cable is known for its durability and strength, making it a reliable choice for general mining operations.

However, when it comes to reeling applications, the Type 451 cable outperforms the Type 441 due to its enhanced flexibility and improved resistance to the stress of reeling.

This makes the Type 451 better suited for applications like wharf cranes and materials handling, where the cable is subjected to constant winding and unwinding.

While the Type 441 cable offers good flexibility, the Type 451 takes it a step further. Its construction is optimized for environments where cables need to bend and flex repeatedly without suffering from fatigue.

This increased flexibility reduces the likelihood of cracking or breaking, extending the lifespan of the cable in demanding applications.

Both cables are designed to withstand harsh environmental conditions, but the Type 451 offers superior resistance to specific challenges such as extreme temperatures, abrasion, and chemical exposure.

This makes it a better choice for environments where the cable is exposed to a wide range of potentially damaging factors.

The Type 451 Mining Trailing Cable is versatile and well-suited for a variety of applications.

The Type 451 cable is designed for applications that require continuous reeling and unreeling. This makes it an ideal choice for wharf cranes, stackers, and reclaimers in port and materials handling operations.

Its ability to withstand the mechanical stress associated with reeling ensures reliable performance over time.

Wharf cranes operate in a demanding environment, often exposed to harsh weather conditions and heavy loads.

The Type 451 cable is built to handle these challenges, providing the flexibility and durability needed to keep wharf cranes operational and efficient.

In materials handling, where cables must navigate complex pathways and endure constant movement, the Type 451 offers the flexibility and strength needed to maintain performance.

Whether it’s powering conveyor systems, hoists, or other mobile equipment, this cable ensures reliable power delivery.

While the Type 441 is often used in mining operations, the Type 451 cable is also an excellent choice, particularly in scenarios where reeling is required. Its enhanced durability and flexibility make it a strong contender for powering mobile equipment and other machinery in mining environments.

Selecting the right cable for your operations is crucial to ensuring safety, efficiency, and longevity.

The Type 451 Mining Trailing Cable offers several advantages that make it a top choice for industries requiring reeling capabilities and high durability.

The Type 451 cable is specifically designed to excel in reeling applications, providing enhanced flexibility and strength. This optimization ensures that the cable can withstand the repetitive stress of winding and unwinding, reducing the risk of wear and tear.

Whether in a mine, at a port, or in a materials handling facility, the Type 451 cable is built to endure the harsh conditions that are typical of these environments.

Its rugged construction provides excellent resistance to mechanical damage, environmental factors, and electrical stress.

The Type 451 Mining Trailing Cable meets Australian standards, including AS/NZS 1802 and AS/NZS 2802, ensuring that it is safe and reliable for use in Australian mining and industrial operations.

Compliance with these standards is essential for maintaining operational safety and efficiency.

Backed by Feichun Cable’s reputation for quality and reliability, the Type 451 cable is a product you can trust. It has been tested and proven in some of the most demanding environments, making it a reliable choice for your operations.

The Type 451 Mining Trailing Cable is a versatile, high-performance cable that offers improved performance in reeling applications, wharf cranes, and materials handling.

Its enhanced flexibility, durability, and superior electrical performance make it an excellent choice for industries that require reliable power delivery in tough environments.

When compared to the Type 441 cable, the Type 451 stands out for its ability to withstand the mechanical stresses associated with reeling, making it better suited for applications where cables are subject to continuous winding and unwinding.

Additionally, its enhanced resistance to environmental factors ensures that it can maintain its performance even in the most challenging conditions.

Invest in the Type 451 Mining Trailing Cable from Feichun Cable and experience the benefits of a cable designed to meet the specific needs of your operations.

Whether you’re in mining, materials handling, or port operations, the Type 451 offers the performance and reliability you need to keep your equipment running smoothly.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.