Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Impact Resistant: |

Guards Against Impact Damage |

Maximum Tensile Strength: |

20kN |

Jacket Thickness: |

1.52 Mm |

Resistant To Debris: |

Guards Against Mining Debris |

Material: |

Special Compounds |

Abrasion Resistance: |

High |

Certifications: |

CE, RoHS |

Chemical Resilience: |

Withstands Various Mining Chemicals |

Uv Resistant: |

Yes |

Underground Ready: |

Suited For Underground Mining |

Outer Sheath Color: |

Black |

Application: |

Mining |

Grounding Features: |

Includes Grounding For Added Safety |

Durable Construction: |

Long-lasting In Demanding Conditions |

Impact Resistant: |

Guards Against Impact Damage |

Maximum Tensile Strength: |

20kN |

Jacket Thickness: |

1.52 Mm |

Resistant To Debris: |

Guards Against Mining Debris |

Material: |

Special Compounds |

Abrasion Resistance: |

High |

Certifications: |

CE, RoHS |

Chemical Resilience: |

Withstands Various Mining Chemicals |

Uv Resistant: |

Yes |

Underground Ready: |

Suited For Underground Mining |

Outer Sheath Color: |

Black |

Application: |

Mining |

Grounding Features: |

Includes Grounding For Added Safety |

Durable Construction: |

Long-lasting In Demanding Conditions |

In the challenging and often dangerous environment of underground mining, safety and reliability are paramount. The equipment used must be robust, durable, and, above all, safe for the workers who rely on it daily.

Among the essential components of underground mining operations are the towed cables that power heavy machinery and ensure seamless operation.

The Type 409 Heavy-Duty Towed Cable is specifically designed for industrial applications in underground mines, offering unmatched durability, safety, and performance.

This article delves into why this cable is the ideal choice for such demanding environments and highlights its low smoke and halogen-free properties that could make the difference between life and death in a crisis.

Underground mining is one of the most demanding industrial activities, exposing equipment to extreme conditions such as high humidity, temperature fluctuations, and abrasive materials.

The cables used in these operations must be able to withstand not just the mechanical stress of daily use but also the harsh environmental factors that come with working deep below the earth's surface.

1. Durability and Strength

The Type 409 Heavy-Duty Towed Cable is engineered to meet the rigorous demands of underground mining. With heavy-duty construction, this cable is built to resist the wear and tear associated with being towed across rough, uneven surfaces.

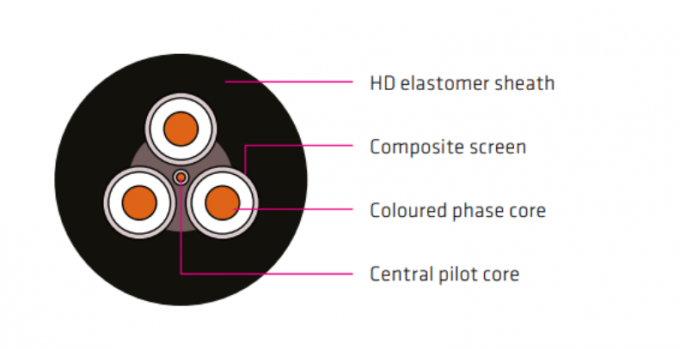

Its reinforced outer sheath is made from materials specifically selected for their abrasion resistance and ability to endure constant friction. This ensures that the cable remains functional and reliable even after prolonged exposure to the harsh conditions typical of mining environments.

2. Flexibility in Harsh Conditions

Despite its strength, the Type 409 cable is also highly flexible. This flexibility is crucial for applications in underground mines where the cable must bend and move with the machinery it powers.

Whether winding through tight spaces or trailing behind moving equipment, this cable maintains its integrity and performance, reducing the risk of breaks or electrical faults.

When it comes to safety in underground mining, low smoke and halogen-free (LSHF) properties are not just beneficial—they're essential. In the event of a fire or electrical fault, the materials used in cables can have a profound impact on the outcome.

Cables that emit toxic smoke or dangerous halogens can exacerbate an already critical situation, leading to severe consequences.

1. The Danger of Smoke in Enclosed Spaces

In the confined spaces of an underground mine, smoke is one of the most dangerous hazards.

It can quickly fill narrow passages, reducing visibility to near zero and making it nearly impossible for workers to find their way to safety. Moreover, the inhalation of toxic smoke can lead to asphyxiation, often before help can arrive.

The Type 409 Heavy-Duty Towed Cable is designed with this in mind. Its low smoke emission properties mean that, in the event of a fire, the amount of smoke produced is significantly reduced.

This not only provides workers with more time to evacuate safely but also minimizes the likelihood of smoke inhalation, a leading cause of fatalities in underground fires.

2. Halogen-Free Materials

Halogens, when burned, release toxic gases that can cause severe harm to anyone exposed to them. In an underground mine, where ventilation is limited, these gases can quickly reach dangerous concentrations.

The Type 409 cable is made from halogen-free materials, ensuring that in the event of a fire, no harmful gases are released. This makes the environment significantly safer for workers, reducing the risk of long-term health issues or fatalities caused by toxic fume exposure.

3. Enhanced Escape Routes

In an emergency, clear escape routes are essential. The low smoke emission and halogen-free properties of the Type 409 cable mean that even in the worst-case scenario, workers have a better chance of finding their way out of the mine safely.

The reduced smoke not only prevents asphyxiation but also ensures that visibility is maintained for as long as possible, allowing workers to navigate their way to safety.

The Type 409 Heavy-Duty Towed Cable is not just built to be tough; it's built to meet the highest safety standards required for underground mining operations. This includes compliance with stringent regulations that govern the use of electrical cables in hazardous environments.

1. Compliance with International Standards

The Type 409 cable complies with key international standards for low smoke and halogen-free cables, making it a trusted choice for mining operations around the world. These standards ensure that the cable performs reliably in the most challenging conditions while also offering the highest level of safety for workers.

2. Designed for Long-Term Performance

In addition to meeting safety standards, the Type 409 cable is designed for long-term performance. Its durable construction means that it can withstand the rigors of daily use in a mining environment, reducing the need for frequent replacements.

This not only cuts down on maintenance costs but also minimizes downtime, ensuring that mining operations can continue without interruption.

3. High-Performance Insulation

The insulation used in the Type 409 cable is specifically designed to withstand the high electrical demands of underground mining machinery. It provides excellent electrical insulation, ensuring that the cable can carry high voltages without the risk of short circuits or electrical faults.

This high level of insulation is crucial in an environment where even a small electrical fault can have catastrophic consequences.

Choosing the right cable for underground mining is about more than just meeting technical requirements—it's about ensuring the safety and reliability of your entire operation.

The Type 409 Heavy-Duty Towed Cable offers a range of benefits that make it the ideal choice for industrial applications in underground mines.

1. Superior Durability

The Type 409 cable is built to last. Its heavy-duty construction ensures that it can withstand the daily wear and tear of underground mining, while its abrasion-resistant sheath protects it from damage caused by rough surfaces and sharp objects.

This durability means fewer cable replacements and less downtime, allowing your operation to run smoothly.

2. Enhanced Safety Features

Safety is the number one priority in any mining operation, and the Type 409 cable delivers on this front.

Its low smoke and halogen-free properties make it a safer choice for underground applications, reducing the risk of smoke inhalation and toxic gas exposure in the event of a fire. This makes it an invaluable asset for any operation where worker safety is paramount.

3. Reliable Performance

In a demanding environment like an underground mine, you need equipment you can rely on. The Type 409 cable offers consistent, reliable performance, ensuring that your machinery has the power it needs to operate efficiently.

Its high-performance insulation and flexible design mean that it can handle the high voltages and tight spaces typical of underground mining without compromising on performance.

4. Cost-Effective Operation

While safety and durability are critical, the Type 409 cable also offers cost-effective operation. Its long lifespan and reduced need for maintenance mean that it represents a sound investment for any mining operation.

By choosing a cable that is designed to last, you can reduce your overall operational costs and ensure that your mine remains productive and profitable.

The Type 409 Heavy-Duty Towed Cable is the ideal solution for industrial applications in underground mines. With its robust construction, low smoke and halogen-free properties, and reliable performance, it meets the unique challenges of the mining environment while prioritizing the safety of workers.

Whether you're looking to enhance the safety of your operation, improve the reliability of your equipment, or reduce your operational costs, the Type 409 cable delivers on all fronts.

Investing in the right cable is investing in the future of your mining operation. With the Type 409 Heavy-Duty Towed Cable, you can be confident that you're choosing a product that is designed to meet the highest standards of safety, durability, and performance—ensuring that your operation can continue to thrive in even the most challenging conditions.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.