Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 200 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Features: |

Oil And Flame Resistant, UV Resistant |

Certifications: |

MSHA Approved |

Uv Resistance: |

Yes |

High Current Capability: |

Efficient High-current Transmission |

Resistant To Debris: |

Guards Against Mining Debris |

Grounding Features: |

Includes Grounding For Added Safety |

Maximum Tensile Strength: |

20kN |

Oil Resistance: |

Yes |

Jacket: |

Special Material |

Impact Resistant: |

Guards Against Impact Damage |

Underground Ready: |

Suited For Underground Mining |

Insulation: |

Special Material |

Material: |

Special Compounds |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Features: |

Oil And Flame Resistant, UV Resistant |

Certifications: |

MSHA Approved |

Uv Resistance: |

Yes |

High Current Capability: |

Efficient High-current Transmission |

Resistant To Debris: |

Guards Against Mining Debris |

Grounding Features: |

Includes Grounding For Added Safety |

Maximum Tensile Strength: |

20kN |

Oil Resistance: |

Yes |

Jacket: |

Special Material |

Impact Resistant: |

Guards Against Impact Damage |

Underground Ready: |

Suited For Underground Mining |

Insulation: |

Special Material |

Material: |

Special Compounds |

Versatile Compatibility: |

Fits Various Equipment Configurations |

In the demanding world of underground mining, having the right cable is crucial to maintaining safety, efficiency, and productivity. The Type 209 Trailing Cable has emerged as a superior substitute for traditional feeder cables in these challenging environments.

Built to withstand the rigors of underground mining, this cable offers several advantages over standard feeder cables, particularly in terms of tensile strength, durability, and flexibility.

This article will explore why the Type 209 Trailing Cable is becoming the preferred choice for miners and how its innovative design and materials make it an exceptional option for your operations.

Underground mining operations require a constant and reliable power supply to keep machinery running smoothly. Traditionally, feeder cables have been used to transmit power from the main electrical supply to various equipment and machines within the mine.

These cables are designed for stationary or semi-stationary applications, where they remain largely fixed in place.

However, the dynamic and often harsh conditions of underground mining demand more than what standard feeder cables can offer. Equipment is frequently moved, repositioned, and subjected to intense mechanical stress, leading to wear and tear that feeder cables may not be able to withstand.

This is where Type 209 Trailing Cables come into play as a superior alternative.

One of the most significant differences between Type 209 Trailing Cables and ordinary feeder cables is their tensile strength. Trailing cables are specifically designed to handle the constant pulling, bending, and dragging that occurs in underground mining operations.

This is achieved by incorporating Kevlar high fiber material—the same material used in bulletproof vests—into the cable sheath. The addition of Kevlar greatly enhances the tensile strength of the cable, allowing it to endure the mechanical stresses without breaking or becoming damaged.

In contrast, ordinary feeder cables are not built to handle such conditions. They are more rigid and less flexible, which makes them prone to damage when subjected to the continuous movement and tension typical in underground mining.

This lack of flexibility can lead to frequent cable failures, resulting in costly downtime and repairs.

Type 209 Trailing Cables are constructed with durability in mind. The combination of a tough outer sheath and the internal Kevlar reinforcement makes these cables resistant to abrasion, cutting, and tearing.

This is particularly important in underground mining, where cables are often dragged across rough surfaces, exposed to sharp edges, and subjected to harsh environmental conditions.

Ordinary feeder cables, on the other hand, are more susceptible to damage. Their outer sheaths are typically not as robust, making them vulnerable to wear and tear over time.

This can lead to insulation breakdowns, short circuits, and ultimately, cable failure. By choosing Type 209 Trailing Cables, miners can significantly reduce the frequency of cable replacements and repairs, resulting in lower overall maintenance costs and improved operational efficiency.

Underground mining environments are known for their extreme conditions, including high temperatures, moisture, and exposure to chemicals.

Type 209 Trailing Cables are engineered to perform reliably in these harsh conditions. The Kevlar-reinforced sheath not only provides exceptional tensile strength but also offers resistance to heat, moisture, and chemical exposure.

This ensures that the cable remains flexible and functional, even in the most demanding environments.

Ordinary feeder cables are not designed with these conditions in mind. They may become stiff or brittle when exposed to extreme temperatures or chemicals, leading to potential failures.

In contrast, Type 209 Trailing Cables maintain their flexibility and integrity, making them a more reliable choice for underground mining operations.

The inclusion of Kevlar high fiber material in the Type 209 Trailing Cable is a game-changer. Kevlar is renowned for its incredible strength-to-weight ratio, making it an ideal material for applications where durability and tensile strength are critical.

In the context of trailing cables, Kevlar's properties provide several key benefits:

Enhanced Tensile Strength:

Kevlar's ability to withstand tension without breaking is unmatched, making it the perfect material for reinforcing trailing cables that are constantly pulled, dragged, and bent in underground mining.

Lightweight Durability:

Despite its strength, Kevlar is incredibly lightweight, meaning it adds minimal weight to the cable while significantly increasing its durability. This makes the Type 209 Trailing Cable easier to handle and install.

Heat and Chemical Resistance:

Kevlar's resistance to heat and chemicals ensures that the cable can perform in extreme environments without degrading. This is particularly important in underground mining, where cables may be exposed to high temperatures, oils, and other chemicals.

By incorporating Kevlar into the Type 209 Trailing Cable, the cable's overall performance is greatly enhanced, making it a superior substitute for traditional feeder cables.

The Type 209 Trailing Cable is well-suited for a wide range of underground mining applications, particularly those involving mobile or portable equipment. Some of the key applications include:

Mobile equipment, such as shuttle cars, continuous miners, and drills, require a flexible and durable power source that can move with the equipment. The Type 209 Trailing Cable provides the ideal solution, offering the flexibility and tensile strength needed to withstand the constant movement and mechanical stress.

In underground mining, power often needs to be supplied to equipment located in remote or difficult-to-reach areas. The Type 209 Trailing Cable is capable of transmitting power over long distances while maintaining its integrity and performance. Its durability ensures that it can handle the tough conditions associated with remote power supply.

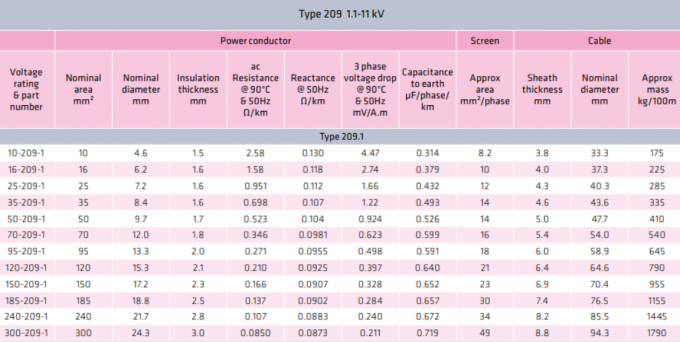

For heavy-duty applications that require high power levels, the Type 209 Trailing Cable is available in various voltage ratings, including Type 209.6 (6.6 kV) and Type 209.11 (11 kV).

These higher voltage cables are designed to deliver consistent power to large machinery, such as draglines and ore crushers, ensuring that even the most power-hungry equipment operates efficiently.

Type-209.1-3C25-SQMM-Mining-Cable-Australia-Standa...

When it comes to underground mining operations, the Type 209 Trailing Cable stands out as a superior substitute for ordinary feeder cables. Its enhanced tensile strength, durability, and flexibility—achieved through the incorporation of Kevlar high fiber material—make it the ideal choice for powering mobile equipment and supplying power to remote areas.

In addition, its ability to withstand harsh environmental conditions ensures that it remains reliable and functional, even in the most demanding underground mining environments.

By choosing Type 209 Trailing Cables over traditional feeder cables, mining operators can reduce maintenance costs, minimize downtime, and improve overall operational efficiency.

Whether you're powering mobile equipment, supplying power to remote locations, or handling heavy-duty applications, the Type 209 Trailing Cable offers the performance and reliability you need to keep your operations running smoothly.

Invest in the Type 209 Trailing Cable today and experience the difference that Kevlar-enhanced durability and superior tensile strength can make in your underground mining operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.