Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: AS/NZS 2802:2000 AS/NZS 1125:2001 And AS/NZS 2802:2003

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 800 Meter

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T, Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Features: |

Oil And Flame Resistant, UV Resistant |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Outer Diameter: |

1.25 Inches |

Chemical Resilience: |

Withstands Various Mining Chemicals |

Material: |

Special Compounds |

Temperature Rating: |

-40°C To 90°C |

Custom Power Solutions: |

Tailored For Equipment Needs |

Jacket Color: |

Black Or Customize According To Needs |

Flexible Handling: |

Easy Handling In Dynamic Conditions |

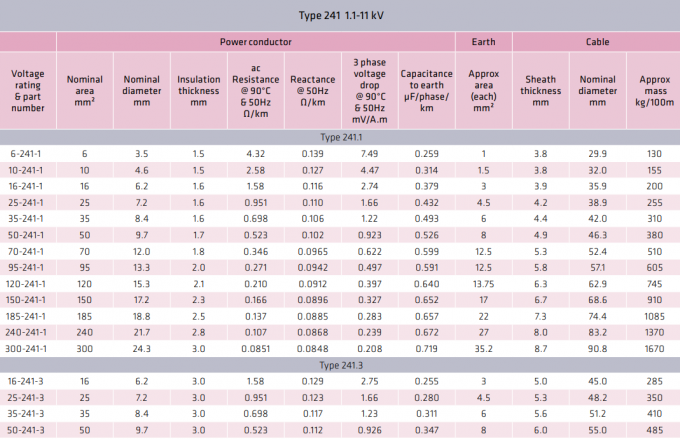

Voltage Rating: |

1.1/1.1 KV To 11/11 KV |

Customizable Lengths: |

Tailored Lengths For Equipment |

Number Of Conductors: |

3 |

Features: |

Oil And Flame Resistant, UV Resistant |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Outer Diameter: |

1.25 Inches |

Chemical Resilience: |

Withstands Various Mining Chemicals |

Material: |

Special Compounds |

Temperature Rating: |

-40°C To 90°C |

Custom Power Solutions: |

Tailored For Equipment Needs |

Jacket Color: |

Black Or Customize According To Needs |

Flexible Handling: |

Easy Handling In Dynamic Conditions |

Voltage Rating: |

1.1/1.1 KV To 11/11 KV |

Customizable Lengths: |

Tailored Lengths For Equipment |

Number Of Conductors: |

3 |

Mining operations are some of the most demanding environments in the industrial world, requiring equipment and materials that can withstand extreme conditions while maintaining reliable performance. One crucial component that powers these operations is the mining cable.

The Type 241 Mining Cable stands out as a top choice for various applications, including continuous miners, feeder cables to pumps, and monorails supplying DCBs (Distribution Control Boxes) and longwalls.

This cable is meticulously crafted to meet the stringent Australian mining cable standard and is particularly suitable for surface open-pit mines. With its strong and UV-resistant construction, the Type 241 Mining Cable is the ideal choice for low-dimensional and high-sunlight environments.

The Type 241 Mining Cable is designed with the specific needs of mining operations in mind.

Engineered for Tough Environments

Mining operations, especially in surface open-pit mines, expose equipment to some of the harshest conditions imaginable.

The Type 241 Cable is engineered to handle these conditions, providing reliable performance even in extreme temperatures, high UV exposure, and environments where mechanical stress is a constant factor.

Versatile Applications

This cable is incredibly versatile, making it suitable for a wide range of mining applications.

Whether you’re powering continuous miners, providing feeder cables to pumps, or supplying monorails for DCBs and longwalls, the Type 241 Cable delivers consistent performance. Its adaptability to various tasks in the mining sector makes it a cost-effective and efficient solution.

Compliance with Australian Mining Cable Standards

Compliance with the Australian mining cable standard is not just a mark of quality; it’s a testament to the cable’s ability to perform under the most challenging conditions.

The Type 241 Cable meets and exceeds these standards, ensuring that it can handle the rigorous demands of mining operations in Australia and beyond.

UV Resistance for High-Sunlight Environments

One of the key features of the Type 241 Cable is its UV-resistant outer sheath. This makes it particularly well-suited for open-pit mines where the cable is exposed to direct sunlight for extended periods.

The UV resistance ensures that the cable’s performance remains consistent over time, reducing the risk of degradation and the need for frequent replacements.

Durability and Mechanical Strength

Mining operations involve a significant amount of mechanical stress, whether it’s from heavy machinery, constant movement, or harsh environmental factors.

The Type 241 Cable is built to withstand these stresses without compromising its integrity. Its durable construction ensures that it can endure the physical demands of mining operations, providing reliable power transmission where it’s needed most.

The Type 241 Mining Cable is designed to excel in a variety of mining applications. Here’s how it can be utilized:

Continuous Miners

Continuous miners are critical in the excavation process of underground coal mines, requiring a robust and reliable power source. The Type 241 Cable provides the durability and electrical integrity needed to power these machines effectively, ensuring continuous operation and minimizing downtime.

Feeder Cables to Pumps

In mining operations, pumps are essential for managing water levels and other fluids. The Type 241 Cable serves as a dependable feeder cable, providing the power needed to keep these pumps running efficiently. Its ability to handle harsh conditions makes it ideal for this critical application.

Monorails Supplying DCBs and Longwalls

Monorails play a vital role in transporting equipment and materials in mining operations. The Type 241 Cable is used to supply power to DCBs and longwalls via these monorails, ensuring that the entire system operates smoothly.

Its flexibility and strength make it perfect for this application, where reliability is paramount.

Surface Open-Pit Mines

The cable’s UV-resistant properties and robust construction make it particularly well-suited for surface open-pit mines. In these environments, cables are often exposed to harsh sunlight and need to withstand significant wear and tear.

The Type 241 Cable delivers the durability and performance required to keep operations running smoothly in these demanding conditions.

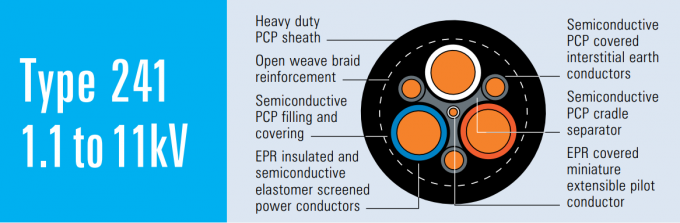

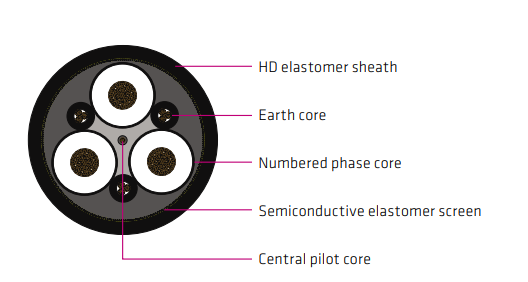

The Type 241 Cable is meticulously engineered to meet the demands of mining environments. Let’s break down its structure and components to understand why it’s so effective:

Conductor:

The cable features high-quality copper conductors, which provide excellent electrical conductivity and durability. Copper is the preferred choice in mining applications due to its ability to withstand harsh conditions while maintaining reliable power transmission.

Insulation:

The insulation layer of the Type 241 Cable is crafted from premium materials that offer excellent resistance to heat, moisture, and mechanical stress. This insulation is crucial for preventing electrical faults and ensuring the safe operation of the cable in challenging environments.

Sheath:

The outer sheath of the cable is designed to resist cuts, abrasions, and UV radiation. This sheath is the first line of defense against environmental factors, protecting the inner components of the cable and ensuring a long service life.

Armoring:

For added protection, the Type 241 Cable is often armored to provide extra mechanical strength. This is particularly important in mining operations where the cable may be subjected to heavy loads and physical stress.

Compliance with the Australian mining cable standard is a key feature of the Type 241 Cable.

Safety

Cables that comply with these standards have been rigorously tested for safety, ensuring that they can be used in hazardous environments without posing a risk to workers or equipment.

The Type 241 Cable meets these safety standards, providing peace of mind that it will perform reliably under the most challenging conditions.

Durability

The Australian mining cable standard also ensures that cables are built to last. The Type 241 Cable has been tested for resistance to environmental factors like moisture, dust, and UV radiation, ensuring a long service life and reducing the need for frequent replacements.

Performance

Compliance with these standards means that the cable will perform consistently, even under the most demanding conditions.

This reliability is essential in mining operations, where downtime can be costly and dangerous.

Adaptability

The Type 241 Cable is designed to adapt to various mining environments, whether it’s in underground tunnels or open-pit mines.

Its compliance with Australian standards ensures that it can handle the unique challenges of these environments while maintaining optimal performance.

In conclusion, the Type 241 Mining Cable is a meticulously crafted solution designed to meet the specific needs of mining operations.

Whether you’re powering continuous miners, feeder cables to pumps, or supplying monorails for DCBs and longwalls, this cable delivers the durability, reliability, and performance required to keep your operations running smoothly.

With its UV-resistant sheath, robust construction, and compliance with the Australian mining cable standard, the Type 241 Cable is particularly well-suited for surface open-pit mines and environments where low-dimensional spaces and high sunlight are factors.

Its versatility and adaptability make it the ultimate choice for miners looking for a cable that can withstand the harshest conditions while delivering consistent performance.

Investing in the Type 241 Mining Cable means choosing a product that is engineered for success, ensuring that your mining operations remain efficient, safe, and productive.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.