SHD-GC Flat Mining Trailing Cable for 10kV Applications: Providing Flexibility and Reliability in Mining Operations

The mining industry demands heavy-duty, durable cables to power essential equipment, often in harsh and challenging environments. The SHD-GC Flat Mining Trailing Cable for 10kV Applications is specifically designed to meet these demands, offering flexibility, high voltage capacity, and exceptional durability.

This cable is purpose-built for 10kV applications, ensuring reliable performance for mining machinery, trailing applications, and other high-power equipment essential for mining operations.

In this comprehensive product introduction, we’ll explore the unique benefits of the SHD-GC flat mining trailing cable and highlight why it’s a top choice for mining professionals around the globe.

We’ll also look at key specifications, customization options, and industry use cases to demonstrate the cable's value in various mining environments.

Key Features of SHD-GC Flat Mining Trailing Cable

| Feature |

Description |

| High Voltage Capacity |

Rated for 10kV applications, ideal for powering heavy-duty mining equipment. |

| Flat Cable Design |

Flat shape provides enhanced flexibility, making it easier to route in tight or confined mining spaces. |

| Durability in Harsh Environments |

Weatherproof, oil-resistant, and abrasion-resistant for reliable use in rugged conditions. |

| Safety Features |

Flame-retardant materials reduce fire hazards, making it safer for both workers and equipment. |

| Enhanced Flexibility |

Designed to move with mobile mining equipment, reducing strain and wear on the cable. |

The SHD-GC cable is engineered to meet the intense demands of the mining industry, where reliability and safety are paramount.

What Makes SHD-GC Flat Mining Trailing Cable Ideal for Mining Operations?

The SHD-GC Flat Mining Trailing Cable stands out in the mining industry for its unique blend of durability, safety, and flexibility. Here’s why this cable is a great fit for mining machinery and trailing applications:

High Voltage Capacity

Designed to support 10kV applications, this cable is ideal for heavy-duty mining equipment that requires high voltage power. Whether for surface mining or underground mining, the 10kV flat cable provides reliable power to machinery that operates continuously.

Flat Design for Enhanced Flexibility

The flat cable design is highly advantageous in mining applications. Flat cables are easier to handle in confined spaces, and they distribute stress more evenly across the cable. This makes the SHD-GC flat cable ideal for trailing cable applications where flexibility is essential.

Exceptional Durability for Harsh Conditions

Mining environments are notoriously tough, and cables often need to withstand abrasion, oil exposure, and weather extremes. The SHD-GC cable is engineered with abrasion-resistant and oil-resistant materials to handle these conditions, while also being flame-retardant for added safety.

Reduced Downtime with Reliable Performance

Unplanned equipment failures can be costly in the mining industry. The durable mining cable design of the SHD-GC minimizes downtime, ensuring continuous operation of critical machinery in harsh environments.

Customizable for Specific Mining Needs

Every mining operation has unique requirements. The SHD-GC trailing cable can be tailored with specific features to meet particular demands, from extended lengths to additional insulation layers.

Technical Specifications of SHD-GC Flat Mining Trailing Cable

To understand the robust performance of the SHD-GC Flat Mining Trailing Cable, let’s delve into its technical specifications:

| Specification |

Details |

| Voltage Rating |

10,000 volts (10kV) |

| Cable Construction |

Flat design with multiple cores |

| Sheath Material |

Oil-resistant, abrasion-resistant, and weatherproof compounds |

| Temperature Range |

-40°C to +90°C, suitable for a wide range of operating conditions |

| Flexibility |

Designed for movement with mobile equipment, allowing for constant flexing and bending |

| Flame Retardancy |

Meets industry standards for flame-retardant materials, reducing fire risks |

| Shielding |

EMI (Electromagnetic Interference) shielding to maintain clear communication and power transfer |

This combination of high voltage capacity, durability, and safety features makes the SHD-GC cable ideal for mining operations that require heavy-duty, high-voltage cables.

Comparison with Traditional Mining Cables

How does the SHD-GC flat mining trailing cable compare to standard mining cables? Let’s break down the differences:

| Feature |

SHD-GC Flat Mining Trailing Cable |

Standard Mining Cable |

| Voltage Capacity |

Up to 10kV |

Typically up to 1kV–5kV |

| Design |

Flat for flexibility and ease of routing |

Round, less flexible |

| Durability |

Highly resistant to oil, abrasion, and weather |

Varies, often less durable in harsh conditions |

| Flexibility |

High, designed for mobile applications |

Moderate, not ideal for constant movement |

| Safety Features |

Flame-retardant, with high resistance to environmental stress |

Varies, often lower fire resistance |

The SHD-GC cable outperforms traditional mining cables, offering greater durability and flexibility, which are crucial in demanding mining environments.

Applications of SHD-GC Flat Mining Trailing Cable

SHD-GC mining trailing cables are widely used in both underground mining and surface mining operations. Here’s how this cable supports various types of mining equipment:

| Application |

Description |

| Draglines and Shovels |

Powering large-scale digging equipment that requires high voltage and flexibility for continuous movement. |

| Conveyor Belt Systems |

Provides reliable power for conveyor systems that transport mined materials over long distances. |

| Drilling Equipment |

High voltage capacity and flexibility make it suitable for powering drills in confined underground spaces. |

| Loaders and Mobile Machinery |

Ideal for mobile equipment that requires a trailing cable capable of constant flexing and movement. |

| Pumps and Ventilation Systems |

High voltage support ensures continuous operation of essential underground safety systems. |

These applications highlight the versatility of SHD-GC flat trailing cables in powering various critical mining equipment.

Customization Options for SHD-GC Flat Mining Trailing Cable

Mining operations often have unique requirements, and the SHD-GC cable can be customized to meet those specific needs. Here are some of the customization options available:

| Customization Option |

Benefits |

| Extended Lengths |

Custom lengths available to reduce the need for connectors in long-distance applications. |

| Additional Insulation Layers |

Extra insulation for enhanced protection in extreme temperature or chemical exposure environments. |

| Enhanced Sheath Materials |

Additional resistance to chemicals, oil, and abrasion, prolonging the cable’s lifespan. |

| UV-Resistant Coating |

Ideal for surface mining operations where cables are exposed to direct sunlight for long periods. |

| Temperature-Resistant Design |

Available for extreme cold or heat conditions, ensuring reliable performance in various climates. |

These customization options enable mining companies to optimize the cable for their specific operational requirements, resulting in greater efficiency and reduced maintenance.

Installation and Maintenance Tips for SHD-GC Mining Cables

Proper installation and maintenance are key to maximizing the lifespan and performance of the SHD-GC trailing cable.

Installation Tips

Minimize Bending During Installation

Avoid sharp bends, especially near connectors, to prevent internal damage to the cable’s cores and insulation.

Secure Properly to Mobile Equipment

Ensure that the cable is securely attached to mobile machinery to prevent excessive strain on connectors and reduce the risk of wear.

Use Protective Covers in High-Wear Areas

Where the cable is subject to high abrasion or impact, apply protective coverings to extend its lifespan.

Maintenance Tips

Regular Inspections

Conduct routine checks for wear, abrasion, and damage, especially in high-use areas. Early detection of wear can prevent costly downtime.

Replace Damaged Sections Promptly

Replace damaged sections to maintain consistent performance and avoid potential hazards in high-voltage applications.

Clean Periodically

Remove dust, oil, and debris buildup, particularly in areas where the cable is exposed to lubricants or other chemicals.

These tips help ensure that the SHD-GC cable performs optimally in the challenging conditions of mining environments.

Why Choose SHD-GC Flat Mining Trailing Cable for 10kV Applications?

The SHD-GC flat mining trailing cable is a top choice for mining professionals due to its unique combination of flexibility, durability, and high voltage capacity. Here are the key reasons to choose this cable:

Reliability: Designed for## SHD-GC Flat Mining Trailing Cable for 10kV Applications: Providing Flexibility and Reliability in Mining Operations

In the mining industry, where equipment reliability and power are critical, the SHD-GC Flat Mining Trailing Cable for 10kV applications is an indispensable solution. This heavy-duty mining cable delivers outstanding flexibility, durability, and safety, ensuring uninterrupted power for essential equipment in surface and underground mining operations.

Let’s explore why this 10kV high-voltage cable is a trusted choice for mining professionals worldwide, focusing on its key features, specifications, and practical applications.

Key Features of SHD-GC Flat Mining Trailing Cable

| Feature |

Description |

| High Voltage Capacity |

Rated for 10kV applications, this cable is ideal for high-power mining equipment, supporting machinery that demands steady, reliable power supply. |

| Durable Sheathing |

Made with abrasion-resistant, oil-resistant, and flame-retardant materials, this cable withstands harsh conditions in rugged environments. |

| Flat Cable Design |

The flat design is easier to route in confined spaces, providing enhanced flexibility, especially in tight mining areas. |

| Safety Standards Compliance |

Meets stringent flame-retardant standards, reducing fire hazards and protecting both personnel and equipment. |

| High Flexibility |

Engineered to handle constant movement with mobile mining equipment, minimizing strain on the cable and extending its life. |

The SHD-GC cable is purpose-built for mining machinery, offering a safe, durable, and flexible power solution designed for the industry’s toughest conditions.

Technical Specifications of SHD-GC Flat Mining Trailing Cable

To fully appreciate the cable’s robust performance, let’s review its technical specifications:

| Specification |

Details |

| Voltage Rating |

Up to 10,000 volts (10kV) |

| Cable Shape |

Flat, which allows flexibility and space-saving design |

| Temperature Range |

Operates effectively from -40°C to +90°C |

| Sheathing Material |

Oil-resistant, abrasion-resistant, and weatherproof |

| Safety Features |

Flame-retardant, reducing the risk of fire in mining areas |

| Flexibility Rating |

High, designed to accommodate continuous movement |

This combination of high voltage, flexibility, and durable materials ensures that the SHD-GC mining cable can handle the extreme demands of mining applications.

Why Choose SHD-GC Flat Mining Trailing Cable?

Here are a few reasons why this SHD-GC cable stands out in mining operations:

High Voltage for Heavy-Duty Applications

The SHD-GC flat cable is rated for 10kV, making it ideal for high-voltage applications that power large equipment such as drills, loaders, and conveyor systems. This ensures that even the most power-intensive machinery can operate effectively without frequent disruptions.

Exceptional Durability for Harsh Environments

Designed with abrasion-resistant and weatherproof sheathing, this cable endures the rough conditions typical in mining environments, where exposure to oil, chemicals, and temperature extremes is common. Its oil-resistant outer layer helps prevent corrosion and extends the life of the cable.

Enhanced Safety Features

Safety is essential in mining, and the SHD-GC cable meets industry standards for flame-retardant materials, minimizing the risk of fires. This is especially important in underground mining, where safety standards are stringent, and equipment reliability is paramount.

Flat Design for Improved Flexibility

The flat design makes the cable easier to route in confined spaces while offering better flexibility. This feature is beneficial for mobile equipment that requires a trailing cable that can withstand constant movement and bending.

Applications of SHD-GC Flat Mining Trailing Cable

The SHD-GC Flat Mining Trailing Cable is well-suited for a variety of mining applications. Let’s examine a few use cases:

| Application |

Description |

| Draglines and Shovels |

Provides consistent high-voltage power for large digging equipment, essential for efficient material excavation. |

| Conveyor Belt Systems |

Powers conveyor systems that move mined materials, supporting long-distance transportation and reducing downtime. |

| Drilling Equipment |

Supports power needs for drills used in underground mining, where space and flexibility are critical. |

| Loaders and Mobile Machinery |

Ideal for mobile machinery requiring a flexible trailing cable for smooth and safe operation. |

| Ventilation Systems |

Powers vital ventilation systems in underground mining to maintain airflow and safety for workers. |

These applications highlight the versatility and performance of the SHD-GC flat cable across different mining environments.

Customization Options for SHD-GC Flat Mining Trailing Cable

To accommodate unique operational requirements, the SHD-GC cable can be customized with specific options.

| Customization Option |

Benefit |

| Extended Lengths |

Reduces need for additional connectors over long distances. |

| Extra Insulation |

Provides enhanced protection in extreme temperatures and chemical exposure. |

| UV-Resistant Coating |

Ideal for surface mining where the cable is exposed to sunlight. |

| Reinforced Sheathing |

Further increases resistance to abrasions and cuts, prolonging the life of the cable. |

| Temperature-Resistant Design |

Suitable for extreme climates, making it ideal for hot or cold mining environments. |

These options allow mining companies to optimize their cable setup for specific challenges, improving efficiency and reducing the need for frequent repairs.

SHD-GC Flat Cable vs. Traditional Mining Cables

How does the SHD-GC flat mining trailing cable differ from other mining cables? Here’s a quick comparison:

| Feature |

SHD-GC Flat Cable |

Standard Mining Cable |

| Voltage Capacity |

Up to 10kV |

Typically up to 5kV |

| Shape |

Flat, offering flexibility and better routing |

Round, less flexible |

| Abrasion Resistance |

High |

Moderate |

| Safety Standards |

Flame-retardant and oil-resistant |

Often less durable in harsh environments |

| Flexibility |

Designed for mobile applications, continuous bending |

Moderate, not ideal for heavy movement |

With greater durability and flexibility, the SHD-GC cable outperforms traditional mining cables in many critical areas, making it a preferred choice for high-voltage mining operations.

Installation and Maintenance of SHD-GC Mining Cables

For optimal performance and longevity, here are some installation and maintenance tips for the SHD-GC flat mining trailing cable:

Installation Tips

Avoid Sharp Bends

Prevent internal damage by avoiding sharp bends, especially near connectors.

Secure Attachment to Machinery

Attach cables securely to prevent strain on connectors, reducing the risk of damage during movement.

Use Protective Covers

In high-wear areas, protective coverings can extend the life of the cable.

Maintenance Tips

Routine Inspections

Regularly check for wear, abrasion, and damage to catch early signs of stress.

Clean to Remove Debris

Periodic cleaning helps prevent dust, oil, and debris buildup, which can affect cable performance.

Replace Damaged Sections

Promptly replace any damaged sections to maintain the high voltage capacity and avoid safety risks.

Following these steps will help extend the lifespan of the SHD-GC cable and minimize costly repairs.

Why Invest in SHD-GC Flat Mining Trailing Cable?

The SHD-GC flat mining trailing cable is a premier choice for 10kV mining applications because it combines high-voltage capacity, flexibility, and durability in one package.

With customization options and robust construction, this cable adapts to the unique challenges of both underground and surface mining.

Enhanced Durability: Withstands oil, abrasion, and weather, making it suitable for the most challenging mining environments.

10kV Capacity: Powers heavy-duty mining machinery, reducing downtime.

Safety Standards: Flame-retardant and oil-resistant, this cable enhances the safety of your operations.

Customizable Features: Adaptable to specific needs, improving efficiency and reducing the need for frequent replacements.

Incorporating the SHD-GC flat mining trailing cable into your mining operation means a longer-lasting, safer, and more reliable power source for essential equipment.

For mining operators looking to minimize downtime and maximize efficiency, this high-voltage mining cable is a smart investment that pays off in both reliability and operational cost savings.

Key Features

High Voltage Rating:

The SHD-GC cable is designed for 10kV applications, providing a robust solution for high voltage power distribution. This ensures that even the most power-hungry mining equipment can operate efficiently and without interruption.

Flat Design for Flexibility:

Unlike traditional round cables, the flat design of the SHD-GC cable offers enhanced flexibility and easier handling. This is particularly beneficial in mining environments where cables need to be routed through tight spaces or around sharp corners.

Reliability in Harsh Conditions:

Built to withstand the harshest of environments, the SHD-GC cable is wear-resistant and durable, ensuring long-lasting performance even under extreme mechanical stress, such as continuous flexing and abrasion.

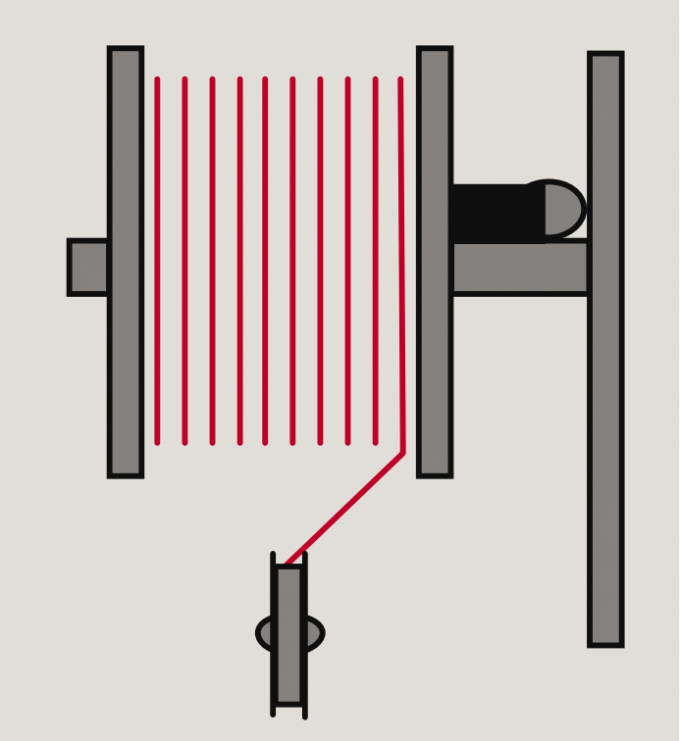

Superior Trailing Capabilities:

The cable's construction is optimized for use with mobile mining machinery, providing excellent trailing capabilities. This means the cable can move with the equipment, offering reliable power transmission without the risk of damage.

Enhanced Safety:

The SHD-GC cable is designed with safety in mind, featuring advanced shielding to prevent electrical faults and reduce the risk of electromagnetic interference (EMI). This is crucial in maintaining stable and safe mining operations.

Applications

Mobile Mining Machinery: Ideal for powering equipment that requires mobility, such as drills, loaders, and conveyors.

Surface and Underground Mining: Suitable for use in both open-pit and underground mining environments, where durability and flexibility are paramount.

High Voltage Power Distribution: Ensures reliable power delivery in 10kV applications, supporting the most demanding mining operations.

Introducing the SHD-GC 10kV Flat Cable, a specialized solution with a flat design tailored for 10kV applications in mining operations.

This cable offers unparalleled flexibility and reliability, ensuring seamless power distribution in demanding mining environments.

With its innovative flat design, the SHD-GC 10kV Flat Cable maximizes space utilization while delivering efficient and dependable performance.

1. What makes the SHD-GC flat cable more suitable for mining operations compared to round cables?

The flat design offers greater flexibility and is easier to install in confined spaces, reducing the risk of damage and improving durability in harsh conditions.

2. Can the SHD-GC cable handle extreme environmental conditions?

Yes, it is engineered to be highly wear-resistant and durable, making it ideal for continuous use in tough mining environments.

3. What safety features are included in the SHD-GC cable?

The cable includes advanced shielding to prevent electrical faults and minimize electromagnetic interference, ensuring safe and reliable operation.

4. Is the SHD-GC cable suitable for both surface and underground mining?

Absolutely, it is designed to perform reliably in both surface and underground mining environments, providing versatility in various applications.

5. How does the SHD-GC cable ensure reliable power transmission?

The cable’s robust design and high voltage rating (10kV) ensure consistent and reliable power distribution, even in demanding mining operations.

Q: What makes the SHD-GC 10kV Flat Cable suitable for mining applications?

A: The SHD-GC 10kV Flat Cable is specifically designed with a flat design for 10kV applications, providing flexibility and reliability in demanding mining operations.

Q: Can the SHD-GC 10kV Flat Cable be customized for specific mining requirements?

A: Yes, the SHD-GC 10kV Flat Cable offers customization options to suit specific operational needs, including length adjustments, specialized insulation, and other bespoke specifications.

Q: What support and services are available for the SHD-GC 10kV Flat Cable?

A: Our comprehensive support includes detailed installation guidance, ongoing maintenance support, and prompt troubleshooting assistance to ensure a seamless experience with the SHD-GC 10kV Flat Cable.