Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun Special

Certification: CSA & MSHA

Model Number: Mining Trailing Power Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

Conductor: |

Copper |

Durable Construction: |

Long-lasting In Demanding Conditions |

High Voltage Capacity: |

Voltage Resilience For Mining |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Ease Of Installation: |

Installs Efficiently In Mining Environments |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Robust Conductor: |

Efficient Conductive Material |

Oil And Chemical Resilient: |

Resists Oils And Chemicals |

Conductor: |

Copper |

Durable Construction: |

Long-lasting In Demanding Conditions |

High Voltage Capacity: |

Voltage Resilience For Mining |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Ease Of Installation: |

Installs Efficiently In Mining Environments |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Robust Conductor: |

Efficient Conductive Material |

Oil And Chemical Resilient: |

Resists Oils And Chemicals |

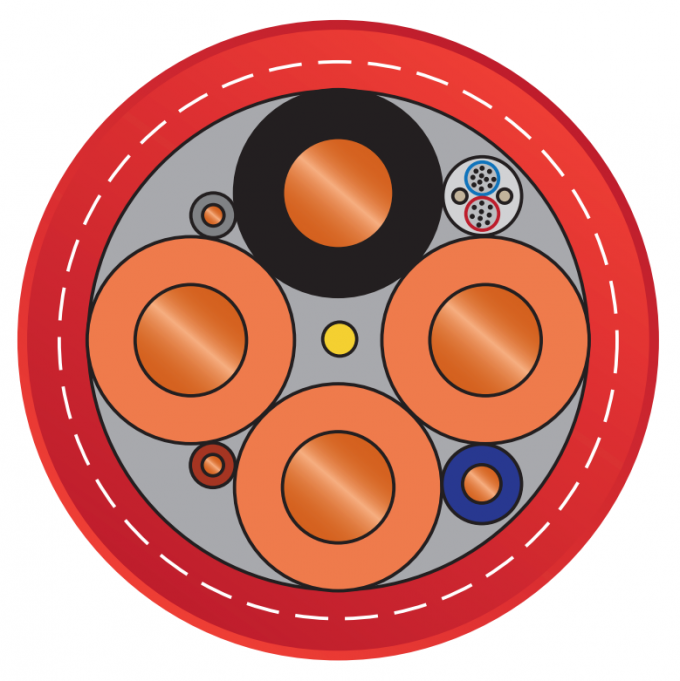

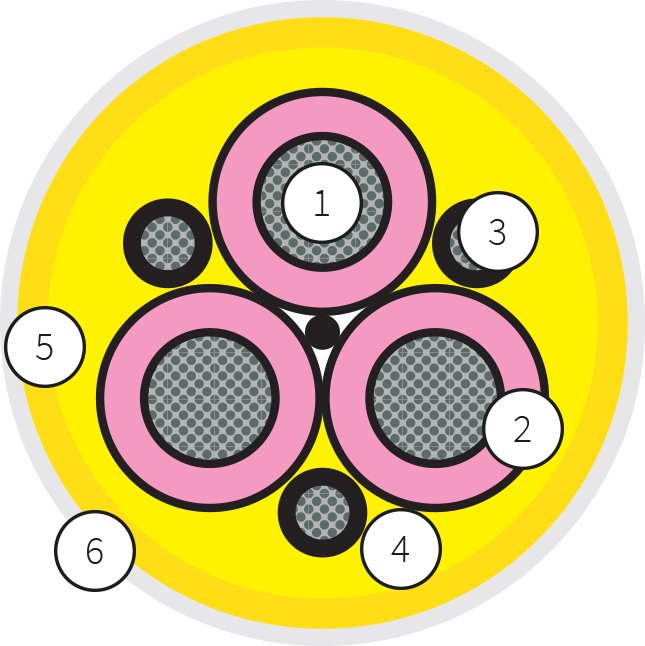

When it comes to mining operations, power transmission cables are an essential component for keeping heavy machinery running efficiently and safely. Our Conductive Mining Trailing Power Cables are designed specifically for the demands of the mining industry, offering high levels of durability, flexibility, and safety to power a range of equipment used in rugged mining environments.

In this article, we’ll explore why our mining cables are ideal for power transmission applications, their key features, technical specifications, and the various benefits they bring to the mining industry. Whether you’re seeking cables that can withstand high voltage, extreme weather, or exposure to abrasive and corrosive elements, our heavy-duty mining cables offer a solution you can rely on.

A mining trailing power cable is designed to supply power to mobile mining equipment, such as drills, loaders, and other heavy-duty machinery. These cables need to be extremely robust, as they often experience continuous movement, tension, and exposure to tough environmental conditions.

To withstand these conditions, our mining cables are engineered with reinforced jackets, advanced insulation, and high flexibility.

Why Choose Our Conductive Mining Trailing Power Cables?

Why Choose Our Conductive Mining Trailing Power Cables?

Our Conductive Mining Trailing Power Cables are built to withstand the roughest conditions. Here are some reasons why our cables are ideal for mining applications:

Conductivity and Efficiency:

With high-quality copper or aluminum conductors, our power cables provide efficient power transmission for high-performance machinery.

Durability:

Designed to be abrasion-resistant, weatherproof, and oil-resistant, these cables ensure that mining operations continue without interruption.

High Voltage Compatibility:

Available in low voltage, high voltage, and extra high voltage configurations to meet the specific needs of different mining equipment.

Safety:

Our cables are flame-retardant and offer options for signal and control cable configurations, enhancing operational safety and control.

Flexibility:

Engineered to be flexible mining cables, they’re easy to install and adjust, supporting smooth movement and reliable power distribution in complex mining environments.

| Feature | Specification |

|---|---|

| Conductor Material | High-purity copper or aluminum for optimal conductivity |

| Voltage Range | Low, High, Extra High Voltage (up to 35kV) |

| Insulation | Flame-retardant and chemical-resistant materials |

| Jacket Material | Heavy-duty, weatherproof, oil-resistant, and abrasion-resistant |

| Flexibility | High flexibility for ease of use in trailing applications |

| Temperature Range | -40°C to 90°C |

| Standards | Meets industry standards for mining operations (IEC, MSHA, etc.) |

| Customization Options | Tailored lengths, diameters, and voltage ratings available |

These cables are well-suited for power transmission in demanding mining environments and can be tailored to specific application needs.

Our heavy-duty mining cables are designed to endure the most challenging environments, including underground mines, open-pit mining operations, and surface facilities. They are resistant to physical wear, providing long-term durability that reduces the need for frequent replacements.

Mining cables often trail along with mobile equipment, making flexibility crucial for minimizing wear and tear. Our flexible mining cables are engineered to follow the movements of heavy machinery, ensuring smooth operations without unnecessary strain.

Safety is paramount in the mining industry. That’s why our flame-retardant mining cables are built to resist fire hazards, while oil-resistant properties make them suitable for oil-exposed settings. These features contribute to safer working environments and longer cable life.

Our mining cables come in low voltage, high voltage, and extra high voltage varieties, allowing for effective power transmission regardless of the equipment’s voltage requirements.

High voltage cables are ideal for high-powered machinery, while low voltage options support auxiliary equipment.

Besides power transmission, we offer control cables for mining as well as signal cables for mining, enabling operators to monitor and control equipment effectively.

This is particularly useful in modern mining environments where remote monitoring is essential.

Underground Mining:

With high resistance to abrasion, water, and chemicals, our durable mining cables are excellent for use in underground mining where environmental conditions are harsh.

Surface Mining:

For surface mining operations exposed to direct sunlight and extreme weather, our weatherproof mining cables offer resilience against UV radiation, temperature fluctuations, and more.

Processing Facilities:

Processing plants that handle oils and chemicals need cables that resist these elements. Our oil-resistant mining cables maintain integrity in such settings, ensuring consistent power supply to processing equipment.

Open-Pit Mining:

In open-pit mines, abrasion-resistant mining cables are crucial for withstanding rocks, dust, and rugged terrain, helping to extend cable life and maintain operational efficiency.

| Cable Type | Application | Voltage Range | Resistance (Abrasion, Oil, etc.) | Flexibility | Flame-Retardant | Weatherproof |

|---|---|---|---|---|---|---|

| Standard Mining Cable | General Power Supply | Up to 600V | Moderate | Low | No | Limited |

| Heavy-Duty Mining Cable | Heavy Machinery | Up to 35kV | High | High | Yes | High |

| Trailing Mining Cable | Mobile Equipment | Up to 1kV | High | Very High | Yes | High |

| Flexible Mining Cable | Dynamic Environments | Up to 6kV | Moderate | High | Optional | Optional |

| Conductive Power Cable | Power Transmission | Variable | Varies | Moderate | Optional | Optional |

This table highlights the range of cable options available, each suited to specific mining applications and requirements.

Our mining cables can be customized to meet unique specifications required by each operation:

Length and Diameter: Choose from a variety of lengths and diameters to match equipment and installation needs.

Voltage Rating: We offer options from low to extra high voltage configurations.

Insulation Materials: We use high-quality, flame-retardant, and abrasion-resistant materials tailored to environmental needs.

Color Coding and Markings: Enhance visibility and identification in complex setups with color-coded insulation options.

Cost Savings: Durable and long-lasting, our cables reduce maintenance and replacement costs over time.

Operational Efficiency: With high flexibility and weather resistance, our cables enhance equipment mobility and uptime.

Enhanced Safety: Flame-retardant, oil-resistant, and abrasion-resistant features protect workers and equipment.

Customization: Tailor-made solutions fit your equipment precisely, offering optimal performance.

Proper installation and maintenance are key to maximizing the lifespan of your mining cables. Here are some tips:

Regular Inspection: Inspect cables for any signs of wear, cuts, or exposure damage.

Proper Handling: Avoid excessive bending or tension to prevent structural damage to the flexible mining cable.

Cleaning: Keep cables clean, especially in dusty environments, to prevent contamination and degradation.

Storage: Store cables in a dry, cool environment when not in use to maintain their integrity.

When choosing a mining cable supplier, consider factors like warranty, product specialization, and reputation in the mining industry.

Our company offers a comprehensive selection of durable mining cables with extended warranties and customization options, making us an excellent choice for reliable, long-term performance.

Mining operations require specialized cables that can handle tough conditions without compromising on efficiency or safety. Our Conductive Mining Trailing Power Cables are crafted to meet the highest industry standards for durability, flexibility, and safety.

Whether you need high voltage mining cables for heavy machinery, flame-retardant mining cables for hazardous areas, or weatherproof cables for outdoor equipment, we provide solutions tailored to your needs.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.