Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: MGM 115/1985

Model Number: Type 7 Turkish Mines Power Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 6,000 meters per week

Compact Design: |

Space-efficient For Easy Handling |

Low Voltage Drop: |

Minimizes Voltage Drop Over Long Distances |

Flexible Mobility: |

High Flexibility For Dynamic Operations |

Easy Termination: |

Simplifies The Termination Process |

Adaptable Bending Radius: |

Allows Flexibility Without Compromising Performance |

Easy Installation: |

Designed For Straightforward And Quick Installation |

Compact Design: |

Space-efficient For Easy Handling |

Low Voltage Drop: |

Minimizes Voltage Drop Over Long Distances |

Flexible Mobility: |

High Flexibility For Dynamic Operations |

Easy Termination: |

Simplifies The Termination Process |

Adaptable Bending Radius: |

Allows Flexibility Without Compromising Performance |

Easy Installation: |

Designed For Straightforward And Quick Installation |

The rugged terrain and challenging environmental conditions of Western Turkey, particularly in provinces like Izmir and Canakkale, call for specialized solutions in the mining industry.

The Type 7 Turkish Mines Power Cable 3×120+50+70 MGM 115/1985 has been meticulously designed and produced to meet the unique demands of this region.

Developed according to the ALSZ Turkish Mining Standard, this cable not only meets but exceeds the stringent requirements needed to ensure safe and efficient operations in the mining sector.

Before diving into the specifics of the Type 7 Turkish Mines Power Cable, it’s essential to understand the significance of the ALSZ Turkish Mining Standard.

This standard is a cornerstone in the Turkish mining industry, providing guidelines and specifications that ensure safety, reliability, and performance in mining operations. The ALSZ standard is particularly relevant in regions with challenging environments, such as the rocky and mountainous areas of Western Turkey.

The ALSZ standard covers various aspects of cable construction, including conductor materials, insulation, sheathing, and overall cable durability.

It ensures that cables used in mining are capable of withstanding the harsh conditions typically found in mines, such as high temperatures, moisture, chemical exposure, and physical wear and tear. By adhering to this standard, the Type 7 Turkish Mines Power Cable guarantees top-notch performance and safety in the most demanding conditions.

Western Turkey, home to notable mining areas like Bergama (Izmir), Kınık (Izmir), Ayvacık (Canakkale), Bayramiç (Canakkale), Çan (Canakkale), and Lapseki (Canakkale), is renowned for its rich mineral resources. The region is particularly known for mining operations involving copper, gold, and lignite.

However, the terrain and environment in these areas present significant challenges, including rocky landscapes, seismic activity, and extreme weather conditions.

To tackle these challenges, the Type 7 Turkish Mines Power Cable 3×120+50+70 MGM 115/1985 has undergone significant enhancements, particularly with its Heavy Duty Chloroprene Sheath. This upgraded sheath material is specifically designed to endure the rugged terrain and fluctuating temperatures commonly found in Western Turkey's mines.

The chloroprene sheath provides excellent resistance to abrasion, chemicals, and extreme weather, making the cable particularly well-suited for open-pit mining and underground operations in this region.

Mining operations rely heavily on the continuous and reliable supply of power to heavy machinery such as excavators and crushers. Any disruption in power can lead to costly downtime and even dangerous situations.

The Type 7 Turkish Mines Power Cable is engineered to ensure that such interruptions are minimized, offering a solution that is as robust as the terrain it is designed for.

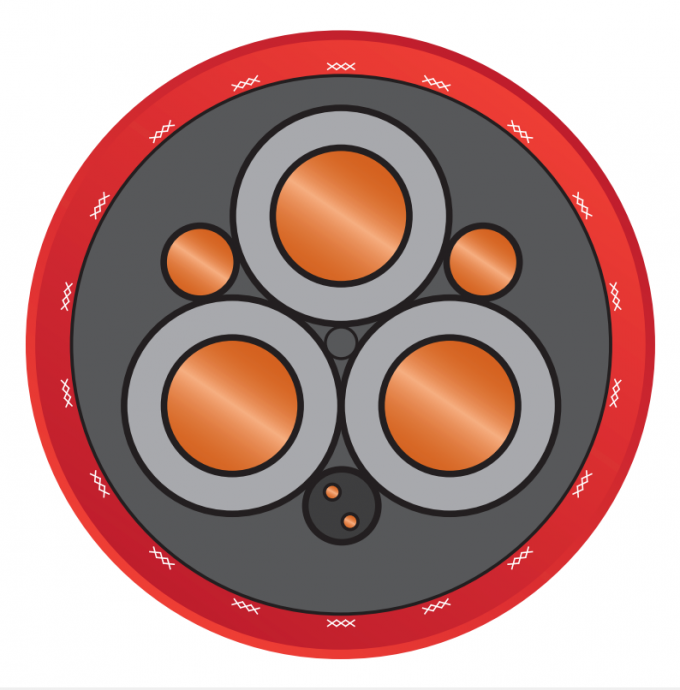

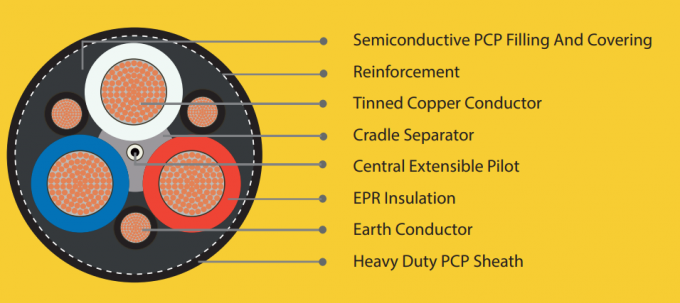

Here’s a breakdown of the cable's key components:

The conductor is the heart of any cable, and in this case, it’s crafted from electrolytic, stranded, tinned copper wire. This material is known for its excellent conductivity and resistance to corrosion, ensuring that the cable performs consistently, even in the harshest conditions.

The IEC 60228 Class 5 specification indicates that the conductor is highly flexible, making it easier to install and maneuver around tight corners in mining environments.

The cable’s insulation is made from EPR (Ethylene Propylene Rubber), a material that offers superior thermal stability and electrical insulation properties.

In the context of mining in Western Turkey, where temperatures can vary dramatically, EPR insulation ensures that the cable maintains its integrity, preventing electrical faults that could lead to power outages or equipment failure.

To simplify installation and maintenance, the Type 7 Turkish Mines Power Cable features a colored textile tape as a separator, making core identification straightforward. This is especially useful in complex mining setups where multiple cables may be running side by side.

The tinned copper/nylon braided screen serves as an additional layer of protection, shielding the cable from electromagnetic interference (EMI) and ensuring that power is delivered without disruption.

This is particularly crucial in mines where electromagnetic fields from other machinery could potentially interfere with power transmission.

The layup of the cable is another critical aspect. In this design, all cores are laid up in contact with the bare earth copper conductor. This configuration enhances the cable’s overall stability and performance, ensuring that it remains operational even under heavy mechanical stress.

The bedding compound used in this cable is rubber-based, providing a cushion that protects the internal components from physical damage. This is particularly important in mining environments, where cables are often subjected to heavy impacts and abrasion.

The Heavy Duty Chloroprene Sheath is the defining feature of this cable. Chloroprene is a material known for its excellent resistance to weathering, chemicals, and mechanical wear.

The heavy-duty nature of this sheath ensures that the cable can withstand the harsh conditions found in Western Turkey’s mining operations, including exposure to water, chemicals, and physical abrasion.

| Cross Section | 3×16+16+16 | 3×25+16+16 | 3×35+18+16 | 3×50+25+25 | 3×70+35+35 | 3×95+50+50 | 3×120+50+70 | |

|---|---|---|---|---|---|---|---|---|

| Phase Conductor | ||||||||

| Number and cross section | mm2 | 3×16 | 3×25 | 3×35 | 3×50 | 3×70 | 3×95 | 3×120 |

| Stranding | mm | 126/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 360/0,50 | 475/0,50 | 608/0,50 |

| Conductor diameter | Nom. mm | 5.50 | 6.75 | 8.00 | 9.75 | 11.60 | 12.75 | 15.10 |

| Insulation thickness | mm | 1.5 | 1.6 | 1.6 | 1.7 | 1.8 | 2.0 | 2.4 |

| Earth Conductor | ||||||||

| Number and cross section | mm2 | 1×16 | 1×16 | 1×18 | 1×25 | 1×35 | 1×50 | 1×50 |

| Stranding | mm | 126/0,40 | 126/0,40 | 147/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 396/0,40 |

| Conductor diameter | Nom. mm | 5.50 | 5.50 | 6.00 | 6.75 | 8.00 | 9.75 | 9.75 |

| Pilot Conductor | ||||||||

| Number and cross section | mm2 | 1×16 | 1×16 | 1×16 | 1×25 | 1×35 | 1×50 | 1×70 |

| Stranding | mm | 126/0,40 | 126/0,40 | 126/0,40 | 196/0,40 | 276/0,40 | 396/0,40 | 360/0,50 |

| Conductor diameter | Nom. mm | 5.50 | 5.50 | 5.50 | 6.75 | 8.00 | 9.75 | 11.60 |

| Insulation thickness | mm | 1.5 | 1.5 | 1.5 | 1.6 | 1.6 | 1.7 | 1.7 |

| Cable details | ||||||||

| Min. overall diameter | mm | 35.8 | 39.7 | 43.1 | 48.5 | 55.1 | 62.4 | 68.0 |

| Max. overall diameter | mm | 40.6 | 44.9 | 47.3 | 53.8 | 60.8 | 68.1 | 78.0 |

| Min. bending radius | mm | 366 | 405 | 426 | 485 | 548 | 613 | 702 |

| Max. pulling tension | kgf | 480 | 642 | 834 | 1.2 | 1.68 | 2 | 2 |

| Appx. cable weight | kg/km | 2.4 | 2.95 | 3.52 | 4.6 | 6.2 | 7.9 | 9.65 |

| Copper weight | kg/km | 1.07 | 1.33 | 1.69 | 2.32 | 3.19 | 4.3 | 5.1 |

| Electrical details | ||||||||

| “Continuous current rating at 25°C Ambient” |

A | 85 | 110 | 135 | 170 | 205 | 250 | 295 |

| “Intermittent current rating at 25°C Ambient” |

A | 96 | 125 | 150 | 200 | 250 | 310 | 355 |

| Max. DC resistance at 20°C | ||||||||

| Phase Conductor | Ω /km | 1.24 | 0.795 | 0.565 | 0.393 | 0.277 | 0.21 | 0.164 |

| Pilot Conductor | Ω /km | 1.24 | 1.24 | 1.24 | 0.795 | 0.565 | 0.393 | 0.277 |

| 3 screens and earth in parallel connection |

Ω /km | 0.7 | 0.6 | 0.6 | 0.5 | 0.34 | 0.28 | 0.26 |

| Nom. reactance at 50Hz | Ω /km | 0.109 | 0.107 | 0.101 | 0.098 | 0.095 | 0.094 | 0.092 |

| Nom. reactance at 60Hz | Ω /km | 0.131 | 0.128 | 0.121 | 0.118 | 0.114 | 0.113 | 0.11 |

| Min. insulation resistance at 20°C |

M Ω /km | 435 | 375 | 325 | 285 | 0.26 | 0.25 | 250 |

| 3 phase voltage drop on full load current |

mV/A/m | 2.62 | 1.68 | 1.2 | 0.84 | 0.61 | 0.47 |

0.38

|

The Type 7 Turkish Mines Power Cable 3×120+50+70 MGM 115/1985 is not just a product; it’s a solution designed specifically for the challenges of mining in Turkey. By adhering to the ALSZ Turkish Mining Standard and incorporating local enhancements, this cable offers unmatched performance and reliability.

In addition to its robust design, this cable is rated for a voltage of 660/1100 V and has been tested at 2.5 kV, ensuring that it meets the highest standards of electrical safety. This makes it an ideal choice for powering heavy-duty mining equipment, such as excavators and crushers, in the mining areas of Izmir and Canakkale.

Mining in Western Turkey is not without its risks. The region’s seismic activity, coupled with its challenging terrain, means that cables used in these mines must be able to withstand not only daily wear and tear but also the potential for natural disasters.

The Type 7 Turkish Mines Power Cable has been designed with these risks in mind.

The Heavy Duty Chloroprene Sheath provides a level of protection that goes beyond standard cables. It’s resistant to both physical damage and chemical exposure, ensuring that the cable remains operational even in the event of an earthquake or other natural disaster.

Additionally, the enhanced screening and insulation materials ensure that the cable maintains its integrity, preventing electrical faults that could lead to equipment failure or safety hazards.

The Type 7 Turkish Mines Power Cable is produced by Feichun Cable, a global leader in the manufacturing of special cables. Located in Hefei, Anhui, China’s science and technology capital, Feichun Cable leverages the scale advantages of China’s manufacturing industry to produce high-quality, affordable cables for a global market.

Feichun Cable is not just a manufacturer; it’s a company deeply invested in innovation. Through its partnership with the University of Science and Technology of China (USTC), Feichun Cable has established a high-level laboratory focused on the research and development of polymer materials.

This collaboration ensures that Feichun Cable remains at the forefront of cable technology, continually improving its products to meet the evolving needs of industries worldwide.

The Type 7 Turkish Mines Power Cable is a prime example of Feichun Cable’s commitment to excellence. By focusing on the specific challenges of mining in Western Turkey and incorporating the latest technological advancements, Feichun Cable has created a product that not only meets but exceeds the expectations of the mining industry.

The Type 7 Turkish Mines Power Cable 3×120+50+70 MGM 115/1985 is more than just a cable; it’s a comprehensive solution tailored to the unique challenges of mining in Izmir and Canakkale, Western Turkey. Designed according to the ALSZ Turkish Mining Standard and enhanced with a Heavy Duty Chloroprene Sheath, this cable offers unparalleled durability, safety, and performance.

Whether you’re operating in the rocky terrains of Bergama or the seismic zones of Çan, this cable is built to withstand the harshest conditions, ensuring that your mining operations continue without interruption. And with Feichun Cable’s commitment to quality and innovation, you can trust that you’re getting a product that’s been engineered to the highest standards.

For mining companies in Turkey looking for a reliable, high-performance cable solution, the Type 7 Turkish Mines Power Cable is the answer. Backed by Feichun Cable’s expertise and the cutting-edge research from USTC, this cable is poised to become the gold standard in Turkey’s mining industry.

Feichun Cable— powering the future of mining, today.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.