Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: VDE 0250 Part 814

Model Number: Malaysia Mining Power Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: Please Contact Our Sales Engineer

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: Please Contact Our Sales Engineer According To The Specific Model

Easy Installation: |

Designed For Straightforward And Quick Installation |

Chemical-Resistant Insulation: |

Resistant To Chemicals In Mining Environments |

Compact Design: |

Space-efficient For Easy Handling |

Application: |

Mining |

Long Flex Life: |

Maintains Flexibility Over Extended Use |

Chemical Resilience: |

Resistant To Common Mining Chemicals |

UV-Resistant Jacket: |

Withstands Exposure To Ultraviolet (UV) Rays |

Adaptable Bending Radius: |

Allows Flexibility Without Compromising Performance |

Easy Installation: |

Designed For Straightforward And Quick Installation |

Chemical-Resistant Insulation: |

Resistant To Chemicals In Mining Environments |

Compact Design: |

Space-efficient For Easy Handling |

Application: |

Mining |

Long Flex Life: |

Maintains Flexibility Over Extended Use |

Chemical Resilience: |

Resistant To Common Mining Chemicals |

UV-Resistant Jacket: |

Withstands Exposure To Ultraviolet (UV) Rays |

Adaptable Bending Radius: |

Allows Flexibility Without Compromising Performance |

Malaysia Mining Power Cable: Designed for the Humid and Hot Areas of Sarawak and Sabah in Borneo

In the mining industry, the choice of power cables is critical to ensuring the safety and efficiency of operations. Cables must be durable, reliable, and capable of withstanding the harsh conditions often found in mining environments.

This need is particularly acute in regions like Sarawak and Sabah in Borneo, where the combination of high humidity, extreme temperatures, and coastal conditions creates unique challenges for standard power cables.

The Malaysia Mining Power Cable, specifically designed for these humid and hot regions, is engineered to meet these demands, ensuring that mining operations continue to run smoothly despite the challenging environmental conditions.

Sarawak and Sabah, located on the northern part of the island of Borneo, are known for their tropical rainforest climates. The environmental conditions here present a range of challenges that standard cables are often not equipped to handle.

Sarawak and Sabah experience consistently high humidity levels, often exceeding 90%, combined with temperatures that regularly reach above 30°C.

These conditions can cause significant damage to cables, accelerating the aging process of materials, leading to insulation degradation, and increasing the risk of electrical failures. High humidity can lead to moisture ingress, which compromises the cable's insulation and overall performance.

The monsoon season in Borneo brings heavy rainfall, particularly in the coastal areas of Sarawak and Sabah. These regions are also prone to typhoons during the summer months, which can lead to flooding and other environmental challenges.

The Malaysia Mining Power Cable is designed to withstand these extreme weather conditions, ensuring that mining operations can continue uninterrupted even in the harshest weather.

The coastal areas of Sarawak and Sabah are often exposed to salt spray and other corrosive elements due to their proximity to the ocean. Over time, these elements can degrade the materials used in standard cables, leading to reduced performance and a shorter lifespan.

The Malaysia Mining Power Cable is designed with materials that resist corrosion, ensuring a longer service life even in the most corrosive environments.

The mining industry in Sarawak and Sabah is diverse, with operations focused on the extraction of a variety of minerals. Some of the most prominent mining areas in these regions include:

Bau Gold Field, Sarawak:

Known for its rich gold deposits, the Bau Gold Field is one of the most significant mining areas in Sarawak. The high humidity and heavy rainfall in this area require cables that can withstand moisture and provide reliable power to mining equipment.

Mamut Copper Mine, Sabah:

Located in the Ranau District, the Mamut Copper Mine was once the largest open-pit mine in Malaysia. Although it has ceased operations, the environmental conditions at the site, including heavy rainfall and high temperatures, highlight the challenges faced by mining operations in Sabah.

Silimpopon Coal Mine, Sabah:

The Silimpopon Coal Mine, although no longer operational, was once a major source of coal in Sabah. The mine's location in a humid and hot region underscores the need for cables that can withstand such challenging conditions.

Kalong Tin Mine, Sarawak:

The Kalong Tin Mine is another example of a mining operation that requires durable cables capable of withstanding high humidity and extreme temperatures.

Sungai Lembing Tin Mine, Sabah:

Located in the coastal areas, this mine is subject to salt spray and corrosive environments, necessitating the use of specially designed cables.

Bintulu Coal Mine, Sarawak:

Bintulu's mining operations face the dual challenges of high humidity and proximity to the coast, making corrosion resistance a key requirement for power cables used in this region.

The Malaysia Mining Power Cable is specifically designed to meet the demands of mining operations in Sarawak and Sabah. Here’s why it stands out:

The cable is made from materials that are resistant to the high humidity and extreme temperatures found in these regions. This ensures that the cable remains reliable and safe, even under the most challenging conditions.

With the coastal areas of Sarawak and Sabah being prone to salt spray and other corrosive elements, the Malaysia Mining Power Cable is designed to resist corrosion, ensuring a longer lifespan and reduced maintenance costs.

The cable is engineered to handle the heavy rainfall and monsoon conditions that are common in Borneo. Its design ensures that it can withstand flooding and other weather-related challenges, providing consistent performance year-round.

The Malaysia Mining Power Cable is manufactured by Feichun Cable, a leading global company specializing in the production of special wires and cables.

Located in Hefei, Anhui Province, the heart of China's manufacturing industry, Feichun Cable leverages the scale advantages of Chinese manufacturing to deliver high-quality, affordable cables to customers worldwide.

Feichun Cable has a deep history of collaboration with the University of Science and Technology of China (USTC), one of the world’s top universities. Through funding and donations, Feichun Cable has established a high-level laboratory that focuses on the research and development of polymer materials.

This partnership ensures that Feichun Cable remains at the forefront of innovation in the cable industry, particularly in developing solutions for special and challenging environments.

| Cross Section (mm2) | Overall Diameter Min. – Max. (mm) | Approximate Weight (kg / km) |

|---|---|---|

| 4 x 16 | 20,00 ± 1,50 | 875 |

| 3 x 25 + 3G6 + 2 x 1,5 | 25,00 ± 1,50 | 1250 |

| 3 x 35 + 3G6 + 2 x 1,5 | 27,30 ± 1,50 | 1600 |

| 3 x 50 + 3G10 + 2 x 1,5 | 31,50 ± 2,0 | 2200 |

| 3 x 70 + 3G16 + 2 x 1,5 | 36,50 ± 2,0 | 3000 |

| 3 x 95 + 3G16 + 2 x 1,5 | 40,50 ± 2,5 | 3750 |

| 3 x 120 + 3G25 + 2 x 1,5 | 44,50 ± 2,5 | 4800 |

| 3 x 150 + 3G25 + 2 x 1,5 | 51,50 ± 2,5 | 5750 |

| 3 x 185 + 3G50 + 2 x 1,5 | 56,50 ± 2,5 | 7300 |

| 3 x 240 + 3G35 + 2 x 1,5 | 61,50 ± 2,5 | 8950 |

The special polyurethane compound jacket provides excellent protection against hydrolysis and oil.

Specifications:

• Rated Voltage: 0.6 / 1 kV

• Max. Operating AC Voltage: 0.7 / 1.2 kV

• Max. Operating DC Voltage: 0.9 / 1.8 kV

• AC Test Voltage: 3.5 kV

• Min. Bending Radius: 6 x D (fixed application), 8 x D (mobile application)

• Current Carrying Capacity: According to VDE 0298 – 4

• Working Temperature:

• Fixed: -40°C up to +80°C

• Mobile: -30°C up to +80°C

• Conductor Operating Temperature: +90°C

• Conductor Short Circuit Temperature: +250°C

• Max. Tensile Load on Conductor: 15 N/mm²

• Max. Torsion: ±25º/m

• Travel Speed:

• In Festoon Systems: Up to 200 m/min

• In Reeling Applications: Up to 60 m/min horizontal

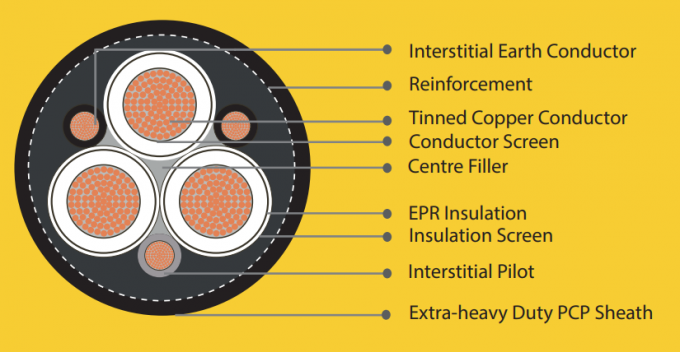

Construction:

• Conductors: Electrolytic, stranded, plain annealed copper wire Class 5 according to IEC 60228

• Insulation: All cores insulated with XLPE (Cross Linked Polyethylene)

• Lay Up: Central aramid (kevlar) strength member, cores laid up in concentric layers with short length of lay

• Inner Sheath: Special extruded Polyurethane compound

• Outer Sheath: Special extruded Polyurethane compound available in yellow, black, or orange

Compliance:

• Construction: Generally to IEC 60502

• General Requirements: DIN VDE 0250-1 and IEC 60502

• Flame Retardant: IEC 60332-1

• Oil Resistant: HD/EN/IEC 60811-2-1, DIN VDE 0473-811-2-1

Feichun Cable’s modern and automated R&D and production base in Hefei ensures that every cable meets the highest international standards.

The company’s focus is not just on solving power supply problems in challenging environments but also on providing global customers with high-quality, durable cables that offer excellent value for money.

The Malaysia Mining Power Cable is more than just a power cable; it is a solution specifically designed to meet the unique challenges of mining operations in Sarawak and Sabah. With its durability, resistance to corrosion, and adaptability to extreme environmental conditions, this cable is the ideal choice for mining companies operating in the humid and hot regions of Borneo.

By choosing Feichun Cable, you are not only investing in a product that meets the highest standards of quality and safety but also partnering with a company committed to innovation and customer satisfaction. Feichun Cable is here to ensure that your mining operations run smoothly, no matter how challenging the environment.

For more information on the Malaysia Mining Power Cable or to request a quote, please contact Feichun Cable today.

Feichun Cable – Empowering the world's toughest industries with cables designed for the future.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.