Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun Special

Certification: ISO CE

Model Number: MINING CABLE

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 6,000 meters per week

Resistant To Debris: |

Guards Against Mining Debris |

Robust Conductor: |

Efficient Conductive Material |

Durable Construction: |

Long-lasting In Demanding Conditions |

Application: |

Mining |

Safety Compliant: |

Meets Safety Standards |

Highly Reliable: |

Trustworthy In Critical Tasks |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Custom Power Solutions: |

Tailored For Equipment Needs |

Resistant To Debris: |

Guards Against Mining Debris |

Robust Conductor: |

Efficient Conductive Material |

Durable Construction: |

Long-lasting In Demanding Conditions |

Application: |

Mining |

Safety Compliant: |

Meets Safety Standards |

Highly Reliable: |

Trustworthy In Critical Tasks |

Efficient Extraction: |

Aids Mineral Extraction Efficiency |

Custom Power Solutions: |

Tailored For Equipment Needs |

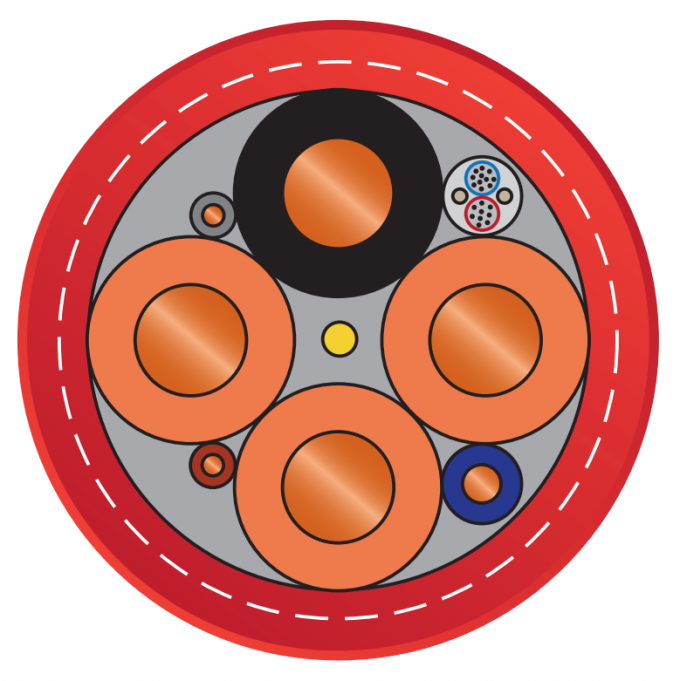

In the rugged world of mining, especially in high-altitude and high-latitude regions, equipment is constantly put to the test by the harshest conditions. Open-pit mines operating in winter face challenges that demand durable, reliable, and efficient power solutions. Enter the EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Strong Wear-Resistant And Tensile-Resistant Mining Cable.

This cable is engineered to withstand the rigors of extreme mining environments, ensuring that your operations run smoothly, no matter how tough the conditions get.

Mining in extreme environments, such as high-altitude or high-latitude open-pit mines, presents unique challenges.

The equipment and materials used in these settings must endure not only the physical wear and tear of daily use but also the extreme temperatures, abrasive conditions, and chemical exposure that can quickly degrade lesser cables.

The EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable is designed to meet these challenges head-on.

This cable offers a combination of wear resistance, corrosion resistance, and cold resistance that makes it ideal for use in the harshest mining environments. Let’s explore what makes this cable a critical asset for mining operations, particularly in challenging settings.

At the core of this cable's durability is the EPR (Ethylene Propylene Rubber) insulation. EPR is widely recognized in the industry for its excellent electrical properties and high resistance to heat, making it a reliable choice for mining cables.

The EPR insulation in this cable ensures that it can handle high voltages and extreme temperatures without compromising on performance.

EPR’s resilience to heat and thermal aging ensures the cable maintains its integrity over time, reducing the risk of breakdowns or power loss. In a mining environment, where electrical reliability is crucial, this insulation provides peace of mind, knowing that the cable can endure the demands of the job without failing.

One of the standout features of this mining cable is its CPE (Chlorinated Polyethylene) outer sheath.

The polymer composite material used in the outer sheath is specifically chosen for its outstanding resistance to the challenges posed by harsh mining environments.

Mining operations involve heavy machinery, sharp tools, and constant friction against rough surfaces.

The CPE outer sheath is highly wear-resistant, ensuring that the cable can withstand the daily abrasions and impacts that come with mining work. This wear resistance translates to a longer cable lifespan, reducing the need for frequent replacements and saving both time and money.

Corrosion is another major concern in mining environments, where cables may be exposed to moisture, chemicals, and other corrosive substances. The CPE material used in the outer sheath offers superior corrosion resistance, protecting the internal components of the cable from degradation.

This is particularly important in mines where chemical exposure is common, as it prevents the cable from deteriorating and maintains its performance over time.

High-altitude and high-latitude mines are often subject to extreme cold, especially during the winter months.

Many materials become brittle and prone to cracking in such conditions, but the CPE outer sheath remains flexible and resilient even in sub-zero temperatures. This cold resistance ensures that the cable remains operational in winter, providing a reliable power supply to mining equipment even when the temperature drops dramatically.

Adding to the durability of this mining cable is the Kevlar reinforcement layer. Kevlar is known for its incredible tensile strength and flexibility, making it an ideal material for reinforcing cables that need to be both strong and flexible.

In mining operations, cables are often subjected to significant tensile forces, whether they are being dragged across rough terrain or pulled into position by heavy machinery.

The Kevlar reinforcement layer provides the tensile strength needed to withstand these forces without stretching or breaking. This makes the cable not only durable but also safe to use in demanding mining applications where tensile stress is a constant factor.

While strength is important, flexibility is equally crucial in mining cables. The Kevlar layer ensures that the cable can be bent, twisted, and maneuvered around obstacles without losing its structural integrity.

This flexibility makes installation easier and helps the cable maintain its performance even in challenging conditions where constant movement and reconfiguration are necessary.

Mining in high-altitude and high-latitude regions, such as those found in Kyrgyzstan, requires specialized equipment that can handle the unique challenges posed by these environments. The EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable is specifically designed to meet the demands of open-pit mines in these areas.

One of the most significant advantages of this cable is its ability to support continuous operations in winter. The cold-resistant CPE outer sheath ensures that the cable remains flexible and operational even in the harshest winter conditions.

This is particularly important for mines that operate year-round and cannot afford to shut down due to cold weather.

The wear-resistant and tensile-resistant properties of this cable make it ideal for use in mines where the terrain is filled with hard rock and abrasive materials like granite and basalt.

These materials can quickly wear down lesser cables, but the CPE outer sheath and Kevlar reinforcement layer provide the protection needed to keep the cable functioning at its best, even in the most abrasive conditions.

In mining operations, the equipment used is often large and powerful, requiring a stable and robust power supply. The EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable is perfect for powering heavy machinery such as excavators, drilling rigs, and conveyor belts.

Its robust construction ensures that it can handle the high power demands of this equipment without compromising on safety or performance.

Whether it's the cold of winter or the abrasive conditions of a granite-filled mine, this cable is designed to withstand the harshest environmental conditions. The combination of EPR insulation, CPE outer sheath, and Kevlar reinforcement makes it an ideal choice for use in areas where traditional cables might fail.

While the initial investment in the EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable may be higher than that of standard cables, the long-term benefits far outweigh the costs.

Its durability, wear resistance, and cold resistance ensure that it will last longer and perform better than lesser cables, reducing the need for frequent replacements and minimizing operational downtime. This makes it a cost-effective solution for mining companies looking to invest in reliable and durable power cables.

Safety is paramount in any mining operation, and the EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable is designed with this in mind. Its robust construction reduces the risk of electrical faults and accidents, ensuring a safer working environment for all.

Additionally, this cable is designed to meet or exceed industry standards for durability and safety, ensuring that your mining operation remains compliant with all relevant regulations.

In conclusion, the EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Strong Wear-Resistant And Tensile-Resistant Mining Cable is a superior choice for mining operations in high-altitude and high-latitude areas. Its combination of EPR insulation, CPE outer sheath, and Kevlar reinforcement layer provides the durability, flexibility, and safety needed to ensure reliable power delivery in the harshest conditions.

For mining companies operating in challenging environments, this cable offers a cost-effective solution that minimizes downtime and maximizes productivity. Whether you're powering heavy machinery, operating in extreme cold, or dealing with abrasive materials, this cable is built to withstand the rigors of the job, ensuring that your operations continue to run smoothly and efficiently.

Investing in the EPR Insulation CPE Outer Sheath Kevlar Reinforcement Layer Mining Cable means investing in the long-term success and safety of your mining operations. With its outstanding features and proven performance, this cable is the cornerstone of reliable power supply in the world’s most challenging mining environments.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.