Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun Special

Certification: VDE 0250 Part 814

Model Number: Mining Trailing Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

Flame Retardant: |

Meets Flame Retardant Standards |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Optimized For Quarrying: |

Designed For Quarrying Applications |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Long Service Life: |

Built For Longevity |

Abrasion-Resistant: |

Tough Against Abrasive Environments |

Abrasion-Resistant Jacket: |

Tough Against Abrasion Damage |

Application: |

Mining |

Flame Retardant: |

Meets Flame Retardant Standards |

Tailored For Handling: |

Enhances Material Handling Efficiency |

Optimized For Quarrying: |

Designed For Quarrying Applications |

Versatile Compatibility: |

Fits Various Equipment Configurations |

Long Service Life: |

Built For Longevity |

Abrasion-Resistant: |

Tough Against Abrasive Environments |

Abrasion-Resistant Jacket: |

Tough Against Abrasion Damage |

Application: |

Mining |

Think about it - every minute of downtime costs you thousands. That's why investing in the right trailing cable for mining isn't just a purchase; it's an insurance policy for your operation's success.

| Performance Factor | Impact on Operations | Cost Implications |

|---|---|---|

| Cable Durability | 40% fewer replacements | Save up to $50K annually |

| Flexibility Rating | 30% easier handling | Reduced installation time |

| Abrasion Resistance | 50% longer lifespan | Lower maintenance costs |

| Temperature Tolerance | -40°C to +90°C operation | Versatile application |

| Feature | What It Means For You | Why It Matters |

|---|---|---|

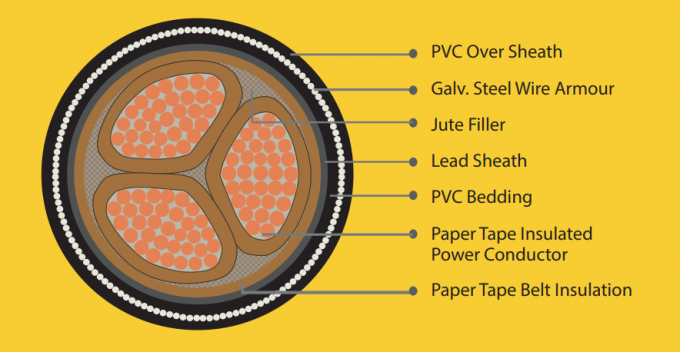

| Enhanced Rubber Compound | Tougher outer jacket | Less damage from rocks and debris |

| Flexible Copper Core | Better bend radius | Easier to handle and install |

| Double Layer Insulation | Extra protection | Fewer electrical failures |

| Reinforced Braiding | Superior strength | Handles more pulling stress |

These aren't your average power cables. They're built specifically for:

Mobile Mining Equipment

Continuous miners

Shuttle cars

Load-haul-dump machines

Drill rigs

Mining scoops

| Equipment Type | Recommended Cable Size | Maximum Length |

|---|---|---|

| Continuous Miner | 3/0 AWG | 1000 ft |

| Shuttle Car | 2 AWG | 800 ft |

| LHD Machine | 4/0 AWG | 1200 ft |

| Drill Rig | 2/0 AWG | 900 ft |

| Mining Scoop | 1/0 AWG | 600 ft |

Let's talk real performance data:

| Test Parameter | Our Cable | Industry Standard |

|---|---|---|

| Abrasion Resistance | 100,000+ cycles | 50,000 cycles |

| Tensile Strength | 25 MPa | 15 MPa |

| Impact Resistance | 40 J/m | 25 J/m |

| Chemical Resistance | Excellent | Good |

Here's where the rubber meets the road - your ROI:

| Timeframe | Direct Savings | Indirect Benefits |

|---|---|---|

| Year 1 | 30% reduced replacement costs | Less downtime |

| Year 2 | 40% maintenance reduction | Improved safety |

| Year 3 | 45% total cost reduction | Higher productivity |

Because safety isn't just a checkbox - it's about sending everyone home at the end of their shift.

| Safety Feature | Benefit | Compliance Standard |

|---|---|---|

| Flame Retardant | Prevents fire spread | MSHA approved |

| High Visibility Jacket | Easy visual inspection | Safety requirement |

| Crush Resistant | Maintains integrity | Mining standard |

| Water Resistant | Operates in wet conditions | IP68 rated |

Making it easy to pick the right cable for your needs:

| Application | Cable Size | Current Rating | Weight/1000ft |

|---|---|---|---|

| Light Duty | 6 AWG | 65A | 180 lbs |

| Medium Duty | 2 AWG | 115A | 320 lbs |

| Heavy Duty | 4/0 AWG | 260A | 980 lbs |

Because proper installation means longer life:

| Installation Step | Key Points | Common Mistakes |

|---|---|---|

| Handling | Use proper equipment | Dragging on ground |

| Laying | Maintain bend radius | Over-tensioning |

| Securing | Use correct supports | Improper clamping |

| Testing | Check continuity | Skipping verification |

Keep your cables performing at their best:

| Timeframe | Check Points | Action Items |

|---|---|---|

| Daily | Visual inspection | Document damage |

| Weekly | Connection check | Clean contacts |

| Monthly | Full testing | Update records |

| Quarterly | Deep inspection | Replace if needed |

Because mining happens in tough conditions:

| Condition | Performance Rating | Notes |

|---|---|---|

| Temperature | -40°C to +90°C | Full range operation |

| Moisture | IP68 | Fully submersible |

| UV Exposure | Excellent | Outdoor rated |

| Chemical Exposure | High resistance | Most mining chemicals |

Investing in quality mining trailing cables isn't just about buying a product - it's about ensuring your operation runs smoothly, safely, and profitably. Our cables are built specifically for the harsh realities of mining environments, backed by real-world testing and actual mining experience.

Ready to upgrade your mining cable system? Let's talk about your specific needs and find the perfect solution for your operation.

Contact our mining specialists today - we speak your language and understand your challenges.

Mining Trailing Cables (крепкий горный кабель) are essential in various mining operations where safety and durability are paramount.

Here are some key application scenarios:

Heavy Machinery Power Supply:

These cables provide a stable power supply to heavy mining machinery such as drills, loaders, and conveyors.

Underground Mining Operations:

Designed to endure the harsh conditions of underground mines, including exposure to moisture, abrasion, and mechanical stress.

Surface Mining:

Suitable for use in open-pit mining where cables need to withstand the elements and heavy-duty usage.

Tunneling Projects:

Ideal for use in tunneling equipment, where flexibility and flame-retardant properties are crucial for safety.

Q1: What makes these cables flame retardant?

Q2: How durable are these cables in harsh mining conditions?

Q3: Are these cables compliant with international standards?

Q4: What are the benefits of using a 4-core trailing cable?

Q5: How flexible are these cables?

Q6: Can these cables be used in both underground and surface mining?

These cables are specifically designed to withstand extreme conditions, provide reliable power, and enhance the overall safety of the mining environment.

Whether for heavy machinery, underground mining, or tunneling projects, investing in high-quality flame-retardant cables can significantly enhance the performance and longevity of your equipment.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.