Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CE、ISO

Model Number: Reeling Drum Cable

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

Bulk Cargo System: |

Supports Cargo Management |

Severe Conditions: |

Thrives In Harsh Environments |

Heavy-Duty Performance: |

Reliable Under Stress |

Industrial Reclaimer: |

Ideal For Reclaiming Processes |

Heavy Equipment Wiring: |

Designed For Robust Machinery |

High Flexibility: |

Adaptable In Dynamic Environments |

Abrasion Resistance: |

Withstands Wear And Tear |

Flexibility: |

High |

Bulk Cargo System: |

Supports Cargo Management |

Severe Conditions: |

Thrives In Harsh Environments |

Heavy-Duty Performance: |

Reliable Under Stress |

Industrial Reclaimer: |

Ideal For Reclaiming Processes |

Heavy Equipment Wiring: |

Designed For Robust Machinery |

High Flexibility: |

Adaptable In Dynamic Environments |

Abrasion Resistance: |

Withstands Wear And Tear |

Flexibility: |

High |

In industries where machinery is constantly in motion, ensuring a stable and durable power supply is essential. One key component to achieving this is the use of oil-resistant and flame-retardant reeling cables, designed to handle the demands of continuous winding and unwinding on large drums.

These cables are specifically engineered to withstand harsh environments, maintain flexibility, and offer maximum durability.

In this article, we’ll dive into the benefits of heavy-duty reeling cables, their various applications, and how they can enhance the operational efficiency and safety of industrial equipment such as cranes, hoists, and material handling machines.

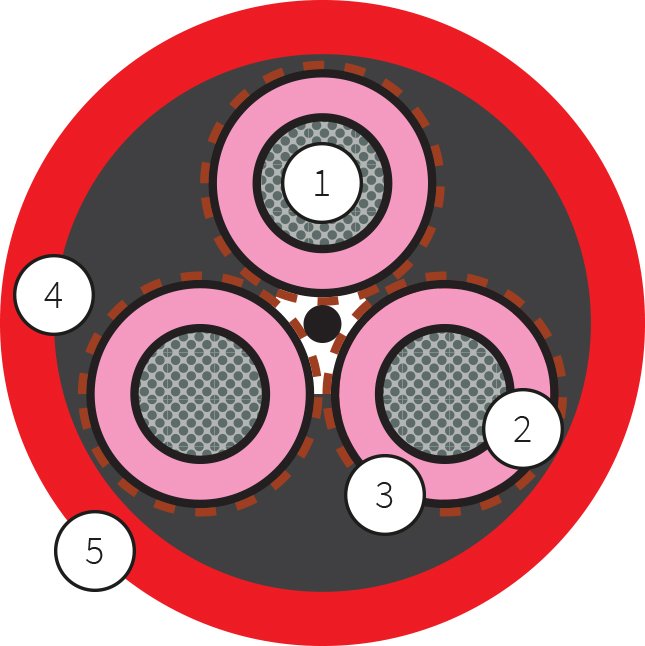

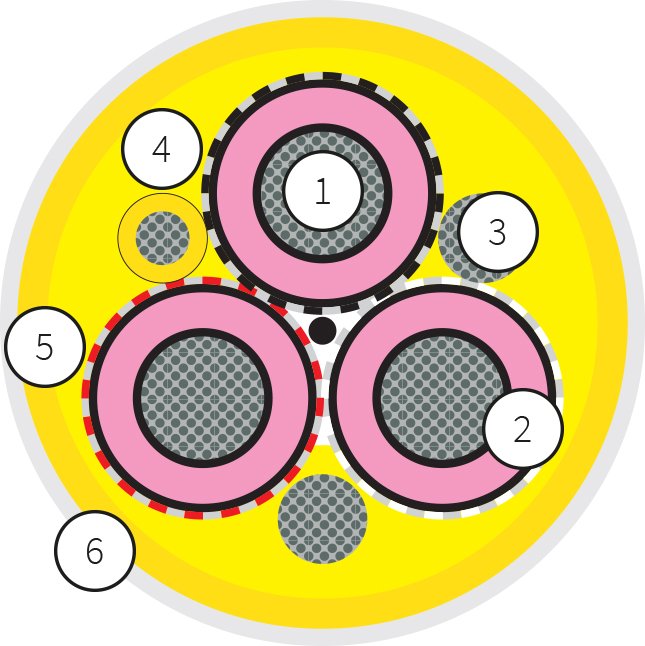

An oil-resistant and flame-retardant reeling cable is a specialized cable designed for heavy-duty, high-stress applications where machinery involves continuous reeling and unreeling. These cables are specifically built for industrial reeling cables applications, where oil resistance and flame retardancy are critical to maintaining safety and functionality.

The oil-resistant component ensures that the cable remains resilient when exposed to oils, lubricants, and greases commonly found in industrial settings. Meanwhile, the flame-retardant feature provides an extra layer of safety by reducing the risk of fire in environments where high temperatures and potential ignition sources are present.

| Feature | Benefit |

|---|---|

| Oil Resistance | Protects the cable from damage when exposed to oils and lubricants, ensuring a longer lifespan. |

| Flame Retardancy | Prevents the spread of fire in case of ignition, improving safety in hazardous environments. |

| High Flexibility | Designed to handle continuous winding and unwinding, these high-flex cables maintain performance under frequent bending stress. |

| Heavy-Duty Construction | Built for tough industrial environments, these cables can withstand high mechanical stresses and rough handling. |

| Durability in Harsh Environments | Resistant to environmental factors such as moisture, chemicals, and mechanical impact, making it ideal for cranes, hoists, and material handling equipment. |

These features make oil-resistant and flame-retardant reeling cables indispensable for industries that rely on continuous movement and need reliable, durable cable solutions.

When dealing with industrial machinery, especially those involving continuous reeling and unreeling operations, choosing the right cable can make a world of difference.

Heavy-duty reeling cables are designed for such applications, offering robust performance in demanding environments.

Industries such as mining, construction, and shipping often expose their equipment to tough conditions. The heavy-duty cable for continuous reeling and unreeling is engineered to withstand extreme mechanical stress, oil exposure, and fluctuating temperatures. This ensures that the cable continues to perform even in the harshest conditions.

The flame-retardant cable characteristic is critical in environments where electrical fires are a potential risk. Whether used in cranes, hoists, or material handling equipment, this cable type reduces the likelihood of fire spreading, offering a safer solution for operators and machinery.

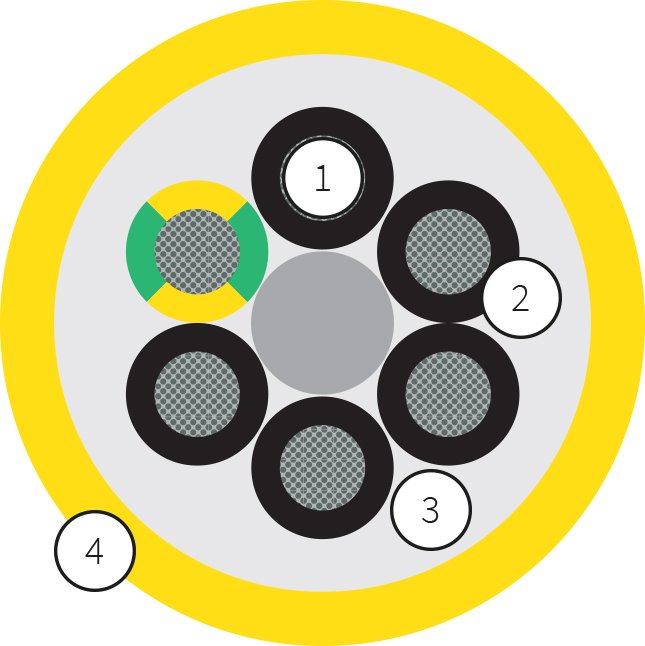

With continuous winding and unwinding, cables must maintain a high degree of flexibility. Flexible cables for large drums are specially designed to provide excellent flexibility, allowing them to handle repeated movements without compromising on performance or durability. This makes them the ideal choice for high-flex cable applications.

The combination of oil resistance and high mechanical stress resistance ensures that these cables have a prolonged service life. This means less frequent replacements and reduced maintenance costs over time, contributing to overall operational efficiency.

The versatility of oil-resistant and flame-retardant reeling cables makes them suitable for various industrial applications. Below is a list of common use cases:

| Application | How the Cable Benefits Operations |

|---|---|

| Cranes and Hoists | Provides reliable power transmission while withstanding continuous reeling and unreeling, essential for smooth crane operations. |

| Material Handling Equipment | Ensures safe and efficient power supply during continuous movement, especially in high-stress environments. |

| Mining and Construction Machinery | Oil-resistant properties ensure the cable remains unaffected by harsh industrial conditions, while flame-retardant features improve safety. |

| Automated Production Lines | The high-flex cable with small bending radius maintains performance under continuous motion, ideal for automated systems. |

| Port and Shipping Operations | Resistant to moisture, oils, and high mechanical stress, making it perfect for environments where heavy machinery is used daily. |

In all these applications, the durability, safety, and flexibility of the industrial cable for harsh environments contribute to improved productivity and reduced downtime.

Here are the technical specifications of a typical heavy-duty reeling cable used in industrial settings:

| Specification | Details |

|---|---|

| Voltage Rating | Suitable for low, medium, and high voltage applications, depending on operational requirements. |

| Temperature Range | Can operate in temperatures ranging from -30°C to +90°C, suitable for use in a wide range of climates. |

| Mechanical Stress Resistance | Built to withstand repeated winding and unwinding under mechanical load. |

| Oil Resistance | Resistant to oils, fuels, and chemicals commonly encountered in industrial environments. |

| Flame Retardancy | Meets industry standards for flame retardancy, ensuring compliance with safety regulations. |

| Bending Radius | Optimized for small bending radii, making it ideal for continuous movement in confined spaces. |

| Cable Diameter | Available in various diameters, depending on application requirements. |

These specifications make the durable cable for frequent winding and unwinding suitable for long-term use in demanding industrial environments.

| Feature | Oil-Resistant and Flame-Retardant Cables | Standard Reeling Cables |

|---|---|---|

| Oil Resistance | High oil resistance, ensuring durability in oily environments. | Susceptible to damage from oil exposure. |

| Flame Retardancy | Meets flame retardancy standards for enhanced safety. | May not provide flame retardant features. |

| Flexibility for Continuous Reeling and Unreeling | Maintains flexibility under repeated mechanical stress. | Less flexible, may wear out faster. |

| Durability | Designed for long service life in harsh environments. | May require more frequent replacement. |

| Cost Efficiency | Higher initial cost, but lower maintenance and replacement costs. | Lower initial cost, but higher long-term costs. |

Choosing an oil-resistant and flame-retardant reeling cable over a standard cable ensures enhanced performance, longer service life, and improved safety, particularly in industries where oil exposure and fire risks are present.

Choosing the right reeling cable for your operation depends on several key factors:

Environmental Conditions: Consider the exposure to oils, chemicals, and extreme temperatures. Oil-resistant cables are essential if your operation involves frequent contact with oils and lubricants, while flame-retardant cables are critical in high-temperature environments.

Mechanical Stress: If your machinery involves frequent movement, select a high-flex cable with a small bending radius to ensure that the cable can withstand continuous bending without compromising performance.

Safety Requirements: Always opt for flame-retardant cables in environments where electrical fires may be a risk. This adds an extra layer of protection for both your equipment and personnel.

Voltage Requirements: Ensure that the cable is rated for the voltage needed for your application. Heavy-duty reeling cables are available for low, medium, and high-voltage applications.

Application Type: Consider the specific machinery you're using. Whether it's for cranes, hoists, or material handling equipment, select a cable designed for continuous reeling and unreeling.

In demanding industrial environments, where continuous motion and exposure to harsh conditions are the norm, investing in the right cable is crucial. The oil-resistant and flame-retardant reeling cable is a top choice for industries that require robust, durable, and safe cable solutions.

With its high flexibility, resistance to oils and chemicals, and flame-retardant properties, this industrial cable for harsh environments ensures long-term reliability and safety.

Whether you are looking for a cable for cranes, hoists, or any other material handling equipment, this heavy-duty cable for continuous reeling and unreeling provides the performance and durability needed to keep your operations running smoothly.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.