Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun™

Certification: CE、ISO

Model Number: Highly Flexible Drag Chain Cable

Payment & Shipping Terms

Minimum Order Quantity: 800 M

Price: 10-50 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 18,000 meters per week

Continuous Monitoring Compatibility: |

Designed For Integration With Monitoring Systems For Real-time Performance Tracking |

Flexible Bending Radius: |

Designed For Dynamic Movements, Accommodating Various Bending Requirements Without Compromising Performance |

Custom Length Configurations: |

Available In Tailored Lengths To Meet Specific Application Requirements |

Modular Installation Options: |

Supports Flexible And Modular Installation, Contributing To Efficient Setup |

Oil And Chemical Resistance: |

Specially Formulated To Resist Industrial Oils, Chemicals, And Contaminants, Ensuring Optimal Performance |

Effortless Installation: |

Designed For Easy And Quick Installation, Minimizing Setup Time |

Available Lengths: |

Custom Lengths Available |

Minimal Maintenance Needs: |

Reduced Maintenance Requirements, Contributing To Overall Cost-effectiveness |

Continuous Monitoring Compatibility: |

Designed For Integration With Monitoring Systems For Real-time Performance Tracking |

Flexible Bending Radius: |

Designed For Dynamic Movements, Accommodating Various Bending Requirements Without Compromising Performance |

Custom Length Configurations: |

Available In Tailored Lengths To Meet Specific Application Requirements |

Modular Installation Options: |

Supports Flexible And Modular Installation, Contributing To Efficient Setup |

Oil And Chemical Resistance: |

Specially Formulated To Resist Industrial Oils, Chemicals, And Contaminants, Ensuring Optimal Performance |

Effortless Installation: |

Designed For Easy And Quick Installation, Minimizing Setup Time |

Available Lengths: |

Custom Lengths Available |

Minimal Maintenance Needs: |

Reduced Maintenance Requirements, Contributing To Overall Cost-effectiveness |

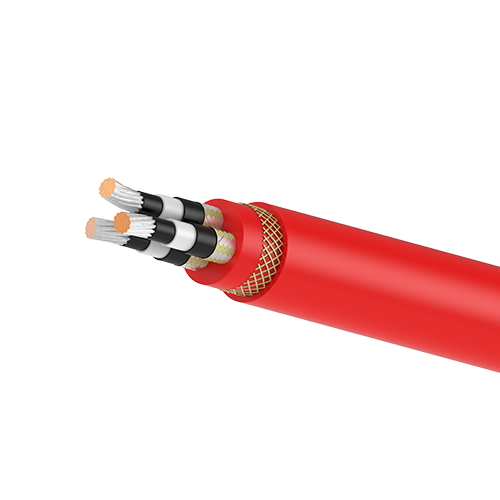

When it comes to industrial applications, especially in environments where drag chains, robotic arms, or moving machinery are involved, choosing the right cable is critical.

For systems that experience high impacts, constant movement, and harsh environmental conditions, highly flexible drag chain cables are an essential component. These cables are specifically designed to withstand the mechanical stresses of high-impact operations while maintaining flexibility and durability.

Impact-resistant drag chain cables are engineered to endure repetitive bending, twisting, and pulling. They are built with robust materials, offering protection from external impacts, as well as oil and chemical resistance, making them a versatile and reliable solution in demanding industrial environments.

Choosing the right cable for your drag chain systems can greatly impact the efficiency and longevity of your machinery. Highly flexible drag chain cables are designed to meet the rigorous demands of continuous-flex operations while providing enhanced protection against impact and wear.

These cables not only extend the lifespan of your equipment but also reduce downtime and maintenance costs, making them ideal for heavy-duty industrial applications.

Impact-resistant for high-impact environments

Continuous-flex design for dynamic applications

Heavy-duty construction for durability and longevity

Oil-resistant and abrasion-resistant materials for harsh industrial environments

Designed for cable carriers and energy chains

Capable of handling high speeds and frequent movements

PUR or TPE jacketed for added protection and flexibility

The primary feature of these cables is their impact-resistant construction. In environments where machinery is subject to physical impacts, whether from moving parts or external forces, these cables provide robust protection.

The cables are reinforced with PUR or TPE jackets, which absorb impact forces and prevent damage to the internal wiring.

| Feature | Benefit |

|---|---|

| Impact-Resistant Design | Withstands high-impact environments without cable failure |

| Reinforced Construction | Protects internal wiring from mechanical stress |

| Heavy-Duty Materials | Increases durability and lifespan in harsh conditions |

In industrial applications, cables are often subject to constant movement, which can cause wear and tear over time. Continuous-flex drag chain cables are engineered to handle millions of flexing cycles, making them the perfect solution for cable carriers, energy chains, and robotic arms.

These cables maintain their integrity even under frequent bending, twisting, and pulling, ensuring that machinery operates smoothly.

| Feature | Benefit |

|---|---|

| Continuous Flexing Capability | Prevents cable fatigue and breakage in dynamic applications |

| Small Bending Radius | Allows for installation in compact spaces |

| High Flexibility | Ideal for robotic arms and other moving machinery |

Industrial environments are often harsh, with exposure to oils, chemicals, and abrasive materials. Highly flexible drag chain cables are made with oil-resistant and abrasion-resistant materials to ensure that they can perform reliably in even the most challenging environments.

These cables are built to last, reducing the need for frequent replacements and minimizing downtime.

| Feature | Benefit |

|---|---|

| Oil-Resistant | Prevents degradation in environments exposed to oils |

| Abrasion-Resistant | Extends cable lifespan in abrasive industrial settings |

| Industrial-Grade Construction | Suitable for harsh and demanding applications |

In industries such as manufacturing, automotive, and material handling, drag chains are often used to protect and guide cables in dynamic systems. Impact-resistant drag chain cables are specially designed to endure the constant movement and mechanical stress that these systems impose.

They ensure that operations run smoothly, without frequent cable replacements or failures.

| Application | Benefits of Drag Chain Cables |

|---|---|

| Cable Carriers | Protects cables in dynamic systems |

| Energy Chains | Ensures reliable performance under constant movement |

| Material Handling Equipment | Withstands high impacts and frequent flexing |

In robotic arms and other automated machinery, cables need to withstand rapid and continuous movements. Highly flexible drag chain cables are specifically designed to handle these conditions, providing superior flexibility and impact resistance.

Their reinforced construction ensures that the cables remain intact even in high-speed, high-impact environments.

| Application | Benefits of Drag Chain Cables |

|---|---|

| Robotic Arms | High flexibility for smooth, precise movements |

| Automated Machinery | Withstands frequent movement and impact forces |

| Dynamic Systems | Reduces cable wear and tear, ensuring longer service life |

Many industries, such as steel manufacturing, mining, and construction, require cables that can handle extreme conditions. Highly flexible drag chain cables are built to perform in oil-resistant, abrasion-resistant, and impact-prone environments.

These cables are designed to work in challenging industrial settings, from extreme temperatures to abrasive materials, ensuring that your systems remain operational.

| Application | Benefits of Drag Chain Cables |

|---|---|

| Mining Equipment | Impact-resistant for tough industrial environments |

| Construction Machinery | Handles extreme temperatures and mechanical stress |

| Steel Manufacturing | Abrasion-resistant for prolonged service in rough conditions |

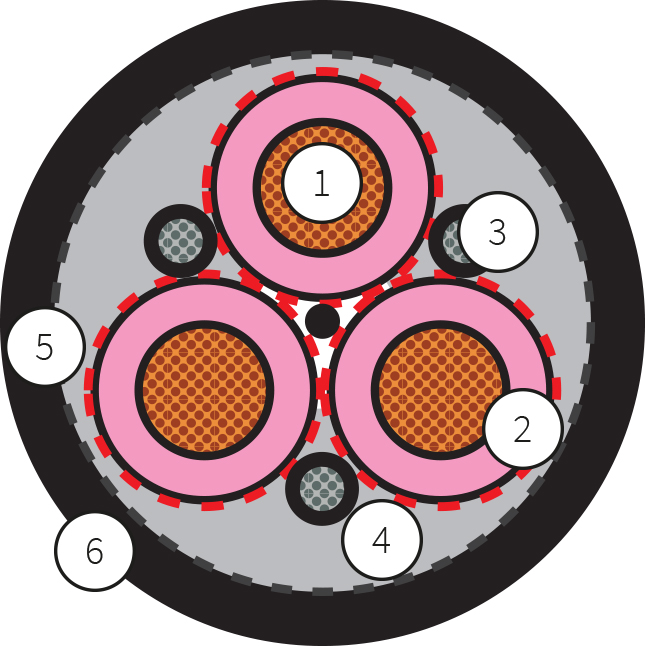

It’s important to understand the technical specifications of these cables to ensure they meet the specific needs of your application. Below are the key technical details for impact-resistant drag chain cables.

| Specification | Details |

|---|---|

| Cable Type | Impact-Resistant Drag Chain Cable |

| Jacket Material | Available in PUR or TPE for enhanced protection |

| Oil and Abrasion Resistance | Designed for harsh industrial environments |

| Temperature Range | -40°C to +90°C |

| Voltage Rating | Up to 600V |

| Bending Radius | Small bending radius for compact spaces |

| Flex Cycles | Up to 10 million cycles for continuous flexing |

The reinforced construction of highly flexible drag chain cables ensures that they provide reliable performance even in high-impact environments. These cables are built to withstand continuous motion, frequent impacts, and exposure to harsh chemicals and oils, offering an extended service life.

| Advantage | Benefit |

|---|---|

| Durability | Reduces the need for frequent cable replacements |

| Reinforced Construction | Withstands impacts and mechanical stress |

| Long-Lasting | Reduces maintenance and operational downtime |

By using impact-resistant drag chain cables, dynamic systems such as robotic arms, material handling equipment, and automated machinery benefit from uninterrupted performance. These cables reduce the risk of equipment failure, ensuring smooth operations and increased productivity.

| Advantage | Benefit |

|---|---|

| Continuous-Flex Design | Prevents cable breakage and ensures reliable power/data transmission |

| Impact Resistance | Reduces the chance of cable damage in high-impact settings |

Whether it’s in manufacturing, mining, construction, or robotics, these cables are highly versatile and can be adapted to a wide range of applications. Their flexibility, impact resistance, and durability make them ideal for various industrial uses, providing a reliable solution for complex dynamic systems.

| Advantage | Benefit |

|---|---|

| Versatile Use | Suitable for multiple industries and applications |

| Heavy-Duty Construction | Withstands the demands of different environments |

When selecting the right drag chain cable for your application, consider the following factors:

Flexing Requirements: For applications with constant or frequent movement, a continuous-flex cable is essential.

Impact Resistance: If your environment involves physical impacts, choose a cable with reinforced construction for enhanced protection.

Environmental Conditions: For harsh industrial environments, opt for cables with oil and abrasion-resistant properties.

Bending Radius: Ensure that the cable can handle tight spaces by choosing one with a small bending radius.

Application Type: Depending on whether the cable is for robotic arms, automated machinery, or drag chains, select a cable that’s designed for that specific application.

Highly flexible drag chain cables are an essential part of modern industrial systems, providing a combination of flexibility, durability, and impact resistance. Designed to handle continuous flexing, high-impact environments, and extreme conditions, these cables ensure that machinery runs efficiently with minimal downtime.

By choosing the right cable for your specific application, you can enhance productivity, reduce maintenance costs, and ensure the long-term success of your industrial operations.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.