Product Details

Place of Origin: Hefei Anhui China

Brand Name: FeiChun Special

Certification: CSA & MSHA

Model Number: Type SHD-GC Mining Trailing Cable 3/C 8kV

Payment & Shipping Terms

Minimum Order Quantity: 200 M

Price: 10-30 USD per meter, price varies according to specifications

Packaging Details: Cable Reels or Packaging Bags

Delivery Time: 15-30 Days

Payment Terms: T/T or Western Union

Supply Ability: 12,000 meters per week

Package: |

Wooden Drum |

Conductor: |

Copper |

Material: |

Special Compounds |

Application: |

Mining |

Jacket Color: |

Black Or Customize According To Needs |

Voltage: |

600V / 1000V |

Test Voltage: |

1200V / 2000V |

Jacket: |

Special Material |

Package: |

Wooden Drum |

Conductor: |

Copper |

Material: |

Special Compounds |

Application: |

Mining |

Jacket Color: |

Black Or Customize According To Needs |

Voltage: |

600V / 1000V |

Test Voltage: |

1200V / 2000V |

Jacket: |

Special Material |

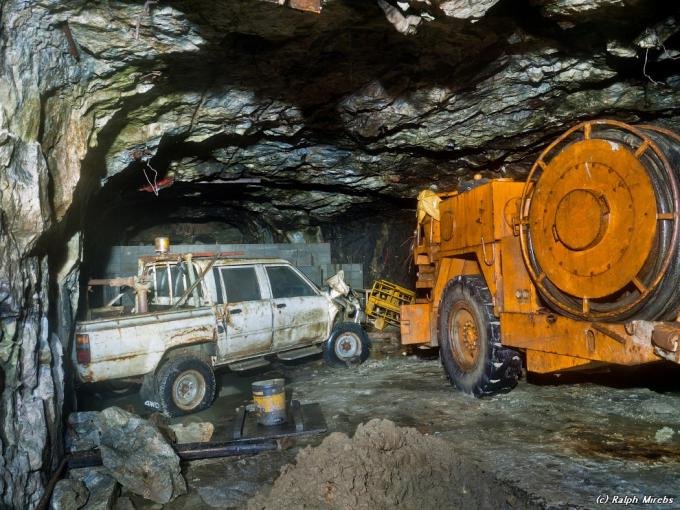

In the rugged and often unpredictable world of open-pit mining, reliability is not just important—it’s essential. The right equipment can make the difference between a successful operation and costly downtime. One of the most critical components in this equation is the power supply, specifically the cables that deliver energy to the heavy machinery.

The Type SHD-GC Mining Trailing Cable 3/C 8kV is a specialized cable designed to meet the high demands of open-pit mining, providing durability, flexibility, and reliability in harsh conditions. In this article, we'll delve into the features and benefits of the SHD-GC series, especially its compliance with North American standards, and explain how to convert American Wire Gauge (AWG) units into square millimeters (SQMM) using scientific calculations.

Mining is a challenging industry where cables are subjected to extreme wear and tear. The Type SHD-GC Mining Trailing Cable is engineered to withstand these challenges. These cables are designed to deliver high voltage power to heavy-duty equipment in open-pit mines, such as draglines, drills, and shovels, ensuring continuous operation without the risk of power failure.

Voltage Rating: With a voltage rating of 8kV, this cable is built to handle the high power demands of large mining machinery. The high voltage ensures that even the most power-hungry equipment can run efficiently and reliably.

Construction: The SHD-GC cable is a 3-conductor (3/C) cable, which means it includes three separate conductors within the same sheath. This construction provides greater flexibility and durability, essential for the rough and often unpredictable environments of open-pit mining.

Durability: Designed to withstand the rigors of mining, the SHD-GC cable features a tough outer sheath that is resistant to abrasion, chemicals, and extreme temperatures. This makes it ideal for use in environments where cables are dragged across rough terrain or exposed to harsh weather conditions.

Flexibility: Despite its robust construction, the SHD-GC cable is highly flexible, allowing it to bend and move with machinery without suffering damage. This flexibility reduces the risk of cable failure and extends the lifespan of the cable.

One of the key selling points of the SHD-GC series is its compliance with North American standards, particularly those set by the Mine Safety and Health Administration (MSHA) and the National Electrical Code (NEC).

This compliance is crucial for mining operations in the United States and Canada, where these standards are mandatory.

MSHA Approval: The SHD-GC cable is MSHA approved, meaning it meets the stringent safety standards required for use in mines across North America. This approval ensures that the cable is safe to use in hazardous environments, where the risk of fire, explosion, or electrical shock is high.

NEC Compliance: The SHD-GC series also complies with the NEC standards, which govern the installation and use of electrical equipment in the United States. This compliance ensures that the cable is not only safe but also compatible with other electrical systems used in mining operations.

One of the challenges when dealing with North American electrical standards is the use of American Wire Gauge (AWG) units, which can be confusing for those more familiar with metric units.

The SHD-GC series is often specified in AWG, so it’s important to understand how to convert these units into square millimeters (SQMM), the standard used in most other parts of the world.

AWG is a standard used primarily in the United States to denote the size of electrical conductors. However, in many other parts of the world, including Australia, cable sizes are measured in square millimeters (SQMM).

Understanding how to convert AWG to SQMM is essential for accurately comparing cable sizes and ensuring that the right cable is chosen for the job.

The conversion from AWG to SQMM is not a straightforward linear calculation, as AWG is a logarithmic scale. However, a simplified version of the conversion formula is as follows:

This formula gives a fairly accurate conversion from AWG to SQMM. For example, if you have a cable that is AWG 4, the conversion would be:

This means that an AWG 4 cable is roughly equivalent to a 21.15 SQMM cable.

Let’s take a look at some common AWG sizes used in the SHD-GC series and their SQMM equivalents:

AWG 8: Approximately 8.36 SQMM

AWG 6: Approximately 13.30 SQMM

AWG 4: Approximately 21.15 SQMM

AWG 2: Approximately 33.63 SQMM

Understanding these conversions can help mining operations ensure that they are using the correct cable size for their equipment, regardless of whether they are working with AWG or SQMM measurements.

The SHD-GC series of trailing cables offers a combination of durability, flexibility, and compliance that makes it the best choice for open-pit mining operations.

Safety: Compliance with MSHA and NEC standards ensures that the SHD-GC cable is safe to use in hazardous environments, protecting workers from the risks associated with electrical failures.

Durability: The tough outer sheath and robust construction make the SHD-GC cable resistant to the wear and tear typical of open-pit mining, reducing the need for frequent replacements and minimizing downtime.

Flexibility: The flexibility of the SHD-GC cable allows it to move with the machinery, reducing the risk of damage from repeated bending and extending the cable’s lifespan.

Versatility: With a voltage rating of 8kV and availability in various AWG sizes, the SHD-GC series is versatile enough to meet the power demands of a wide range of mining equipment.

The SHD-GC series of trailing cables is designed to excel in the harsh conditions of open-pit mining. Here are some common scenarios where these cables are used:

Draglines: Draglines are large machines used in open-pit mining to remove overburden and expose ore. The SHD-GC cable provides the power needed to keep these machines operating smoothly, even in harsh conditions.

Drills: Drills are essential for blasting operations in open-pit mines. The SHD-GC cable ensures that drills receive a consistent power supply, reducing the risk of downtime and increasing productivity.

Shovels: Mining shovels are used to load ore onto trucks for transport. The SHD-GC cable provides the power needed to operate these machines, ensuring that mining operations can continue without interruption.

The Type SHD-GC Mining Trailing Cable 3/C 8kV is a reliable, durable, and versatile choice for open-pit mining operations. Whether you’re powering draglines, drills, or shovels, the SHD-GC series offers the performance and safety needed to keep your equipment running smoothly in the most challenging environments.

With its compliance with North American standards, tough construction, and flexibility, the SHD-GC cable is the best choice for mining operations looking to minimize downtime and maximize productivity.

By choosing the SHD-GC series, mines can ensure that their equipment operates safely and efficiently, reducing the risk of electrical failures and improving overall operational efficiency.

This combination of performance and reliability makes the SHD-GC series the ideal choice for open-pit mining operations worldwide.

Note: This is just part of the standard parameters of our products. Please contact our Engineer if you need more. And the information contained within this webpage is for guidance only and is subject to change without notice or liability. All dimensions and specifications are nominal and are subject to normal manufacturing tolerances. All pictures shown are for illustration purposes only. The actual product may vary. All the information is provided in good faith and is believed to be correct at the time of publication.