In the world of electrical engineering, especially when dealing with mining operations, ports, construction sites, and industrial environments, reeling cables play a crucial role.

These cables are designed to handle repetitive bending and extreme mechanical stress, especially in dynamic conditions like when a cable is coiled or uncoiled from a drum or reel.

However, when it comes to choosing the right reeling cable for these high-stress applications, one term you’ll often encounter is minimum bending radius—particularly in dynamic conditions. Understanding this concept is vital because it can help prevent cable damage, increase the lifespan of your cables, and ensure that your electrical systems operate safely and efficiently.

So, what exactly is the minimum bending radius in dynamic conditions? And why does it matter?

The minimum bending radius is the smallest radius you can bend a cable without causing mechanical or electrical damage. Every cable has its own minimum bending radius based on its design, materials, and application.

It’s a key specification that electrical engineers and technicians must consider when installing cables, especially in environments where cables are frequently bent, such as in reeling applications.

When a cable is bent too sharply, it can cause excessive stress on the internal components, such as the insulation, conductors, and shielding. This can lead to:

Cracking or tearing of the insulation

Breaking or weakening of the conductors

Premature cable failure

Adhering to the minimum bending radius is crucial to ensure that your cable can handle the required tasks without suffering damage over time.

There are two main types of bending radii to consider:

Static Minimum Bending Radius: This applies when the cable is installed in a fixed position, and it will not be moving after installation.

Dynamic Minimum Bending Radius: This applies when the cable is continuously in motion—such as being reeled, unreeled, or bent during operation.

For reeling cables, the dynamic minimum bending radius is of particular interest. These cables are subjected to constant movement, bending, and stress, so the dynamic bending radius is usually more restrictive than the static bending radius.

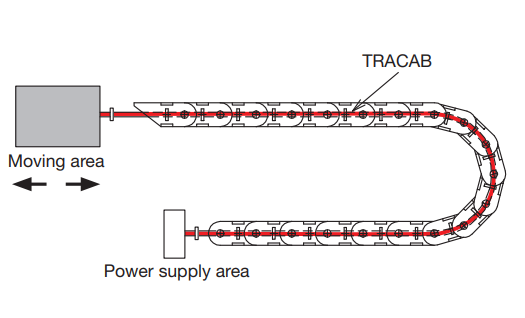

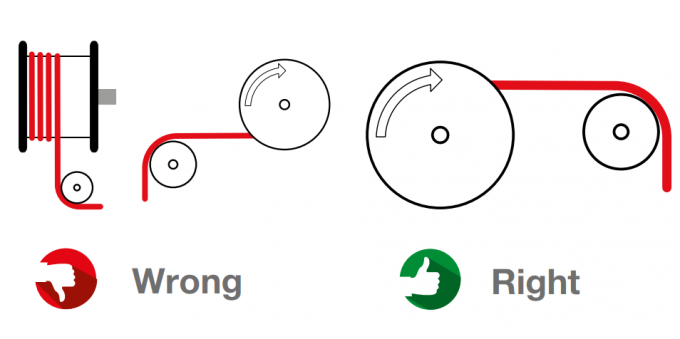

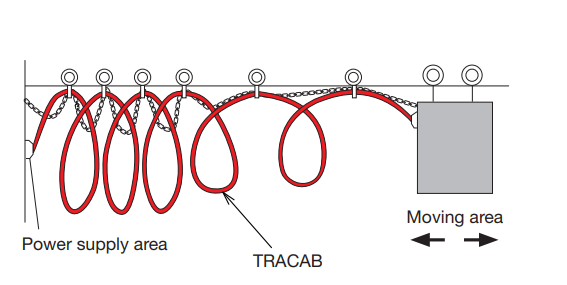

In dynamic conditions, cables are repeatedly bent, stretched, and twisted as they are wound onto and unwound from drums or reels. This constant movement places a significant amount of mechanical stress on the cable. The dynamic minimum bending radius is the smallest allowable radius at which the cable can bend under these moving conditions without suffering degradation.

Ignoring the minimum bending radius in dynamic applications can lead to:

Reduced cable lifespan

Frequent breakdowns

Costly repairs

Increased downtime

For example, in environments like mining operations, where heavy machinery relies on reeling cables to power equipment like shovels, cranes, and draglines, ensuring that these cables are installed and operated within their dynamic bending radius is essential for maintaining safe, reliable, and efficient operations.

The minimum bending radius is typically expressed as a multiple of the cable's outer diameter (OD). The formula looks something like this:

Where "k" is a multiplier determined by the cable's design and material properties. For instance, a typical reeling cable might have a minimum bending radius of 6 times its outer diameter under dynamic conditions.

If a cable has an outer diameter of 50 mm, the dynamic minimum bending radius would be:

This means the cable should not be bent in a radius smaller than 300 mm during operation.

Several factors affect the minimum bending radius of a cable. Here are some of the most important considerations:

Cable Construction: The materials used in the cable's insulation, jacket, and conductors affect how easily the cable can bend without suffering damage. Cables with thicker insulation or more rigid materials will have a larger minimum bending radius.

Number of Conductors: Cables with more conductors tend to be stiffer, leading to a larger bending radius.

Operating Temperature: Higher temperatures can make some materials more flexible, reducing the minimum bending radius. However, excessive heat can also weaken certain materials, so this must be considered carefully.

Operating Voltage: The voltage a cable carries affects its insulation needs, which in turn affects its minimum bending radius.

Cable Usage: Reeling cables that are constantly moved will have a smaller dynamic bending radius than cables that remain static.

Understanding the dynamic minimum bending radius is especially important for industries that rely on reeling cables in tough environments. Here are some key examples:

In mining, reeling cables are used in various applications, including draglines, shovels, and conveyors. These cables are constantly reeled and unreeled as machinery moves around, making the dynamic bending radius a critical factor in preventing cable wear and tear.

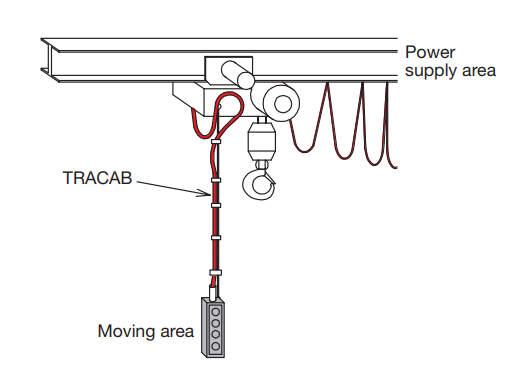

In ports and shipping terminals, reeling cables are used to power cranes, ship unloaders, and other heavy-duty equipment.

These cables must withstand frequent motion, exposure to the elements, and sometimes extreme mechanical stress, making adherence to the dynamic minimum bending radius vital for maintaining operations.

In construction, reeling cables provide power to mobile equipment like cranes, hoists, and excavators.

These cables are continuously moved, reeled, and unreeled during operation, so ensuring they’re used within their minimum bending radius can help avoid costly breakdowns and delays.

To ensure your reeling cables remain within their dynamic minimum bending radius, here are a few practical tips:

Always select a cable that is rated for dynamic bending in the application where it will be used.

If you’re installing a cable in a reeling or moving application, check the cable’s specification sheet to ensure that it is designed to handle dynamic bending.

When installing a reeling cable, follow the manufacturer's guidelines for the minimum bending radius. Ensure that the cable is not bent more sharply than the specified radius during installation or operation.

Dynamic environments can be hard on cables. Regularly inspect your reeling cables for signs of wear or damage, especially in areas where the cable is bent. Replace cables that show signs of cracking, insulation wear, or other mechanical damage.

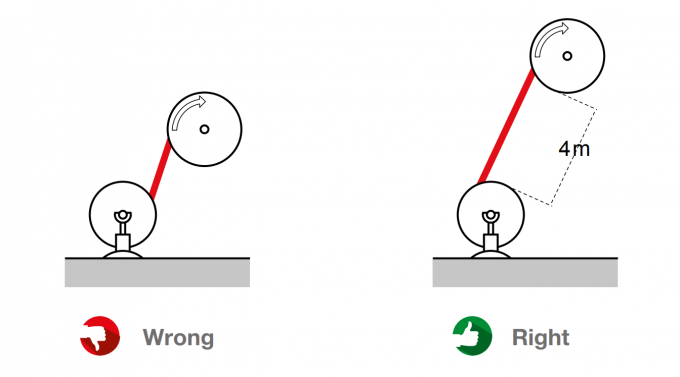

Ensure that the cable reel or drum you are using is the correct size. The drum’s diameter should be larger than the cable’s minimum bending radius to prevent the cable from being bent too tightly.

At Feichun Cable, we understand the demands placed on reeling cables in dynamic conditions. That’s why we design our mining cables, crane cables, and industrial power cables with a focus on meeting the highest standards of performance, safety, and durability.

Our cables are constructed with high-quality materials and engineered to provide optimal flexibility, even in dynamic conditions. This ensures that our cables can handle the stresses of reeling and unreeling while maintaining a long service life and safe operation.

Moreover, we provide detailed specifications for all our cables, including the minimum bending radius for both static and dynamic conditions.

This helps our customers choose the right cable for their specific application, ensuring reliability and efficiency in the field.

In dynamic environments like mining, ports, and construction sites, understanding the minimum bending radius of reeling cables is critical.

Choosing the right cable and ensuring that it operates within its bending limits will help you avoid costly downtime, extend the life of your cables, and keep your operations running smoothly.

At Feichun Cable, we are committed to providing high-performance, durable reeling cables designed for the toughest applications.

Whether you’re looking for cables for mining, ports, or heavy-duty construction equipment, we have the expertise and the products to meet your needs.

For more information about our reeling cables and to find the right cable for your operation, contact us today!

What is the difference between static and dynamic bending radius?

The static bending radius applies when a cable is not in motion, while the dynamic bending radius is for cables that are in motion, such as being reeled or unreeled.

Why is the dynamic minimum bending radius important?

The dynamic minimum bending radius ensures that cables can bend without suffering damage during operation. Ignoring this can lead to premature cable failure and costly repairs.