In the world of industrial operations, crane reel systems play an essential role in powering large-scale lifting and moving equipment. These systems are widely used in various applications such as ports, construction sites, warehouses, and manufacturing plants, where the need for reliable power to cranes, hoists, and other heavy machinery is crucial.

At the heart of these systems lies the crane reeling cable, which is specifically designed to provide a continuous flow of power to cranes as they move along their tracks or lift loads. This article will explain what crane reel systems are, the purpose of crane reeling cables, the unique features of high-quality reeling cables, and the best methods to test these cables for durability and performance.

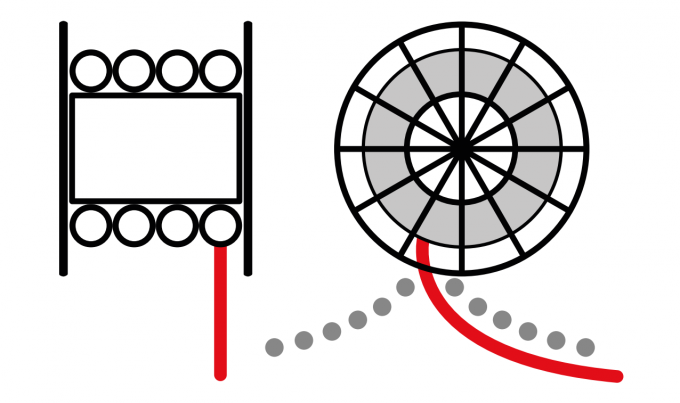

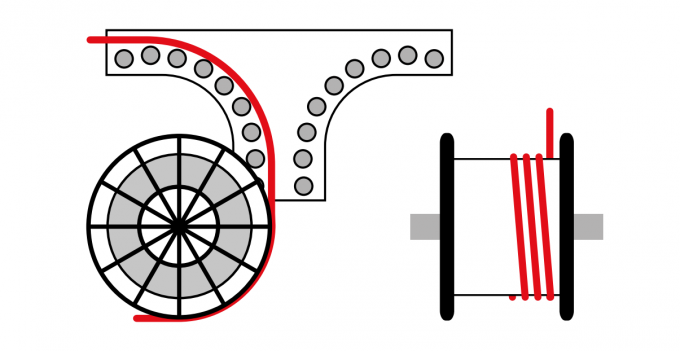

A crane reel system is designed to supply electrical power to moving cranes, especially where the crane must cover long distances or operate in dynamic environments. This is achieved by using a cable reel, which automatically coils and uncoils the cable as the crane moves back and forth.

By reeling the cable in and out, the system ensures that the power cable does not get tangled or damaged, maintaining a smooth and uninterrupted power supply.

Key components of a crane reel system include:

Cable Reel: This component holds the crane reeling cable and ensures that the cable is smoothly reeled in or out as the crane moves. The reel is often motorized to adjust the tension and prevent the cable from slacking or tangling.

Crane Reeling Cable: The critical component that supplies electrical power. Reeling cables are specially designed for extreme flexibility and durability, capable of withstanding constant motion, tension, and environmental stress.

Slip Rings: These devices enable electrical continuity as the reel rotates. Slip rings allow power to flow from the stationary supply source to the rotating reel without any interruption.

The crane reel system is integral to modern industrial crane operations because it ensures that power is delivered safely and efficiently.

Without this system, cranes would face operational hazards such as power loss, cable damage, and increased wear and tear due to the excessive handling of cables.

The crane reeling cable is more than just a simple electrical wire. It is an engineering marvel designed to endure the rigors of industrial use.

The cable must be flexible enough to reel and unreel repeatedly without breaking, but also durable enough to withstand high mechanical stresses such as tension, torsion, and abrasion.

Reeling cables serve several key functions:

Power Transmission: Reeling cables carry electrical power from a stationary source to the mobile crane or hoist, allowing the equipment to perform its tasks such as lifting, moving, or loading heavy materials.

Signal Transmission: In addition to power, reeling cables may also carry control signals and data, ensuring that the crane can communicate with its control system. This is particularly important in modern automated crane operations where precise movements are controlled remotely.

Environmental Protection: Reeling cables are exposed to harsh conditions, including extreme temperatures, moisture, oil, and chemicals. They are designed with robust outer sheaths that protect the internal conductors from damage caused by these environmental factors.

Flexibility and Durability: The cables are made to withstand the constant motion of reeling and unreeling. This is achieved through the use of high-flexibility conductors, reinforced insulation materials, and robust jackets that resist mechanical damage and environmental wear.

Not all reeling cables are created equal. The difference between a high-quality crane reeling cable and a substandard one can make a significant impact on your crane's performance and the overall safety of the operation.

Here are the major distinctions between high-quality and low-quality reeling cables:

High-quality reeling cables are manufactured using superior materials, such as fine-stranded copper conductors for maximum flexibility and high-grade insulation materials like neoprene or polyurethane for enhanced durability. These materials ensure the cable can endure the high mechanical stresses of reeling operations and resist environmental factors like heat, cold, oil, and chemicals.

On the other hand, low-quality reeling cables may use inferior materials that degrade quickly under stress. This leads to frequent breakdowns, posing risks to safety and productivity.

A high-quality reeling cable is designed for extreme flexibility, with conductors that can bend and twist without breaking. The cable’s structure allows it to handle the constant motion of reeling in and out while maintaining its integrity.

Low-quality cables often lack this level of flexibility, and they may suffer from internal conductor damage, insulation cracking, or jacket wear after only a short period of use. This can result in electrical faults, downtime, and costly repairs.

Reputable manufacturers of high-quality crane reeling cables rigorously test their products to meet or exceed international standards such as IEC, VDE, or UL. These cables are subjected to tests for tensile strength, flexibility, insulation resistance, and environmental durability to ensure they perform reliably in real-world conditions.

Low-quality manufacturers may skip important testing processes or use non-certified materials, resulting in cables that do not perform to the necessary standards. Without the proper testing and certification, these cables are more likely to fail, putting the entire crane operation at risk.

A high-quality crane reeling cable is built to last. These cables can provide years of reliable service, even in the most demanding environments, minimizing maintenance costs and downtime.

Low-quality cables, by contrast, have a much shorter lifespan. They may require frequent replacements and repairs, leading to higher long-term costs and increased safety risks.

To ensure that your crane reeling cable performs reliably, it is crucial to test it thoroughly. Here are some important tests to conduct:

Tensile strength testing involves stretching the cable to assess its ability to withstand tension without breaking. This test is critical for reeling cables because they experience constant tension as they are reeled in and out. Testing the tensile strength ensures that the cable can handle the mechanical loads without suffering damage.

Flexibility testing involves bending and twisting the cable to simulate real-world motion. This test determines how well the cable can endure the constant flexing and coiling that occurs during reeling operations. A high-quality reeling cable should retain its flexibility after thousands of cycles without developing cracks or internal damage.

Insulation resistance testing measures the effectiveness of the cable’s insulation in preventing electrical leakage. This test is essential for safety, as damaged or degraded insulation can lead to electrical faults, short circuits, or even fires.

Reeling cables are exposed to harsh environmental conditions, so it’s important to test their resistance to moisture, oil, chemicals, and extreme temperatures. These tests ensure that the cable can perform reliably in damp or corrosive environments without suffering degradation.

Selecting the right crane reeling cable is critical for ensuring the reliability, safety, and performance of your crane operations. High-quality reeling cables are designed to withstand the constant motion, tension, and environmental stresses associated with crane use. They provide superior flexibility, durability, and protection, ensuring that your crane remains operational even in the most demanding conditions.

When selecting a reeling cable, it’s important to choose a reputable manufacturer that rigorously tests their cables for tensile strength, flexibility, and environmental resistance. Investing in high-quality crane reeling cables not only improves safety but also reduces long-term costs by minimizing cable failures and maintenance.

For more information on selecting the best crane reeling cables for your specific application, contact us today!

We can help you choose a cable that meets your needs and provides reliable performance in your crane reel system.