Mining cables, especially the Type SHD-GC, play an essential role in providing power to heavy-duty mining equipment. These cables are subjected to some of the harshest conditions on the planet, including exposure to moisture, high temperatures, chemicals, and mechanical stresses. In such demanding environments, cable shielding becomes a critical factor in ensuring reliable performance and safety.

Feichun Cable understands the complexities of mining operations and offers advanced shielding solutions for Type SHD-GC mining cables. Selecting the right shielding not only enhances the durability of the cable but also ensures protection against electromagnetic interference (EMI), physical damage, and environmental hazards.

In this article, we will explore the importance of shielding in mining cables, the different types of shielding available, and how Feichun Cable ensures that our products deliver exceptional performance in the most challenging environments.

Shielding in mining cables refers to a layer of material, typically made from metal, that encases the cable’s conductors to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). In a mining environment, electrical noise and interference from nearby equipment can disrupt the signals and performance of cables.

Proper shielding ensures that the Type SHD-GC mining cable operates without interruptions, maintaining power and signal integrity.

The right shielding also provides mechanical protection, reducing the risk of damage from impacts, abrasions, or chemicals. In some cases, shielding may also help in preventing the cable from overheating, which is critical for ensuring safety in high-temperature mining environments.

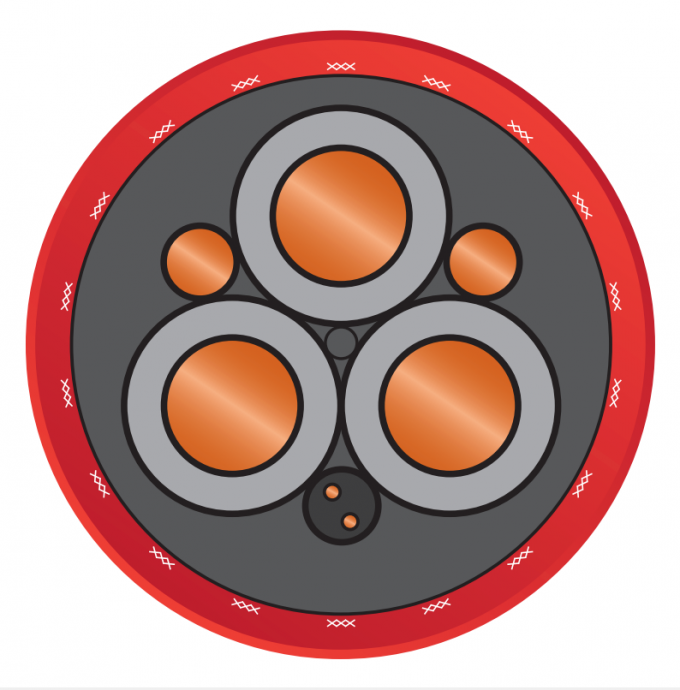

Type SHD-GC cables (Shielded Heavy-Duty Grounded Cable with Ground Check) are specifically designed for mining applications, where they are used to supply power to large, mobile mining equipment such as shovels, draglines, and longwall mining systems. These cables are subjected to extreme conditions, including:

Heavy mechanical stress due to continuous movement and dragging.

Exposure to moisture and chemical substances.

High levels of electromagnetic interference from other equipment operating nearby.

In such scenarios, shielding plays an essential role in ensuring that the cable performs effectively. A well-shielded Type SHD-GC mining cable can reduce electrical noise, prevent voltage drops, and avoid cable failure due to external damage.

This ultimately leads to increased operational efficiency, improved safety, and a longer lifespan for the cable.

There are several types of shielding used in mining cables, each with its own advantages. The most common types of shielding include:

Copper tape shielding is one of the most common forms of shielding in mining cables, including Type SHD-GC.

This type of shielding involves wrapping a thin layer of copper tape around the cable’s conductors, providing excellent conductivity and protection against electromagnetic interference.

Advantages: Copper is highly conductive, making it ideal for blocking EMI and RFI. Additionally, copper tape is flexible, allowing the cable to bend and move without compromising its shielding effectiveness.

Applications: Copper tape shielding is often used in high-voltage cables, where the risk of electrical interference is high. It’s also ideal for mining applications where cables are exposed to intense mechanical movement.

Another common form of shielding is aluminum-polyester foil shielding, where a layer of aluminum foil is laminated to a polyester film, and this combination is wrapped around the cable’s conductors.

Advantages: Aluminum foil provides excellent coverage, ensuring that there are no gaps in the shielding. It is also lightweight, which is beneficial in applications where cable weight needs to be minimized.

Applications: Aluminum-polyester foil shielding is often used in cables that transmit signals and data, as it provides excellent protection against electromagnetic interference. It’s commonly seen in control and instrumentation cables used in mining operations.

Braided shielding consists of tightly woven strands of metal (usually copper or aluminum) that form a mesh around the cable’s conductors. This type of shielding provides both EMI protection and physical strength.

Advantages: Braided shielding offers high durability and flexibility, making it ideal for mining environments where cables are subject to repeated bending and flexing. It also provides a higher level of mechanical protection than other types of shielding.

Applications: Braided shielding is often used in high-flexibility cables, such as those used in mobile mining equipment, where the cable must endure constant movement and mechanical stress.

In some cases, combination shielding is used to provide enhanced protection. This involves using two or more types of shielding in a single cable, such as copper tape combined with braided shielding.

The combination of different shielding materials can offer superior performance in environments with both high EMI and mechanical stress.

Advantages: By combining different types of shielding, the cable can achieve better protection against both electromagnetic interference and physical damage.

Applications: Combination shielding is often used in high-performance mining cables that require superior durability and signal integrity.

At Feichun Cable, we understand that the right shielding can make a significant difference in the performance and longevity of a mining cable.

That’s why we carefully select the most suitable shielding method based on the specific application and environment where the cable will be used.

Here are some key factors we consider when choosing the best shielding for our Type SHD-GC mining cables:

The choice of shielding depends on the specific application and the type of equipment the cable will power. For example, cables used in longwall mining operations may require braided shielding for superior flexibility, while cables used in stationary mining equipment may benefit more from copper tape shielding for its excellent EMI protection.

Mining environments vary greatly, from underground mines exposed to moisture and chemicals to surface mining operations where the cables are subjected to UV radiation and extreme temperatures.

We take these environmental factors into account when selecting the most appropriate shielding. For instance, in wet or chemical-rich environments, aluminum-polyester foil shielding may be more suitable due to its resistance to corrosion.

Mining cables are often dragged across rough terrain, subjected to tension, and bent repeatedly during use. At Feichun Cable, we ensure that our Type SHD-GC cables are equipped with shielding that can withstand these mechanical stresses without breaking or degrading.

Braided shielding is often the preferred choice in such cases due to its ability to endure constant movement.

The electrical performance of the cable is critical, especially in high-voltage applications. We use high-conductivity shielding materials such as copper and aluminum to ensure that the cable performs reliably even in the presence of electrical noise.

To ensure the reliability and performance of our Type SHD-GC mining cables, we subject the shielding to rigorous testing. Some of the key tests include:

We test the cable’s shielding to ensure that it effectively blocks external electromagnetic interference. This test involves exposing the cable to high levels of EMI and measuring any disruptions in signal or power transmission.

Our cables undergo mechanical stress testing to evaluate the durability of the shielding under extreme conditions. We simulate real-world mining conditions where the cable is subjected to tension, abrasion, and repeated flexing to ensure that the shielding remains intact.

We expose our cables to moisture, chemicals, and extreme temperatures to ensure that the shielding can withstand harsh environmental conditions without corroding or degrading.

When it comes to mining cables, selecting the right shielding is essential for ensuring reliable performance and safety in demanding environments. At Feichun Cable, we take pride in providing Type SHD-GC mining cables with superior shielding solutions that are tailored to the specific needs of the mining industry.

Whether it’s protecting against EMI, ensuring mechanical durability, or providing resistance to harsh environmental conditions, our cables are designed to excel.

For more information on how Feichun Cable can meet your mining cable needs, contact us today. Our team of experts is ready to help you select the best shielding for your specific application and ensure that your mining operation runs smoothly and safely.