When it comes to mining cables, the outer sheath is not just a protective layer—it's a crucial component that ensures the cable can withstand the harsh conditions of the mining environment. Two of the most commonly used materials for these outer sheaths are 5GM5 rubber and PUR rubber.

But what exactly are these materials, and how do they differ chemically? Let’s dive into the details to understand the differences and why choosing the right one matters for your mining operations.

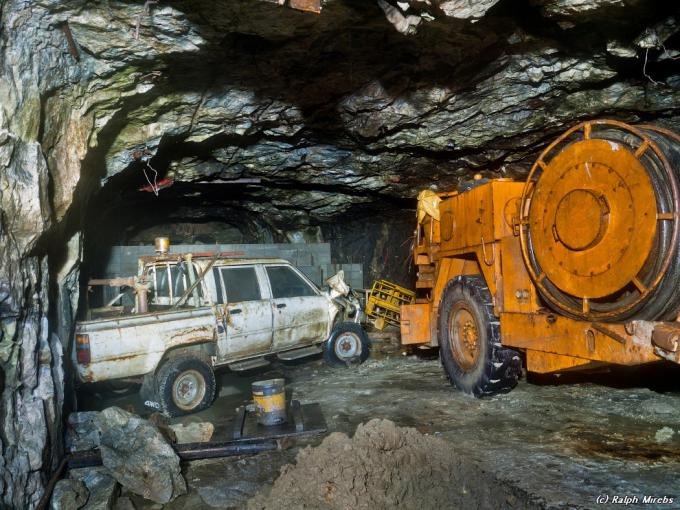

Before we delve into the specifics of 5GM5 rubber and PUR rubber, it’s essential to understand the role of the outer sheath in mining cables. The outer sheath serves as the cable’s first line of defense against physical damage, chemical exposure, and environmental conditions.

Whether the cable is being dragged over sharp rocks, submerged in water, or exposed to corrosive chemicals, the outer sheath must be tough enough to protect the inner conductors.

5GM5 rubber is a high-performance polymer material that has become a staple in the manufacturing of mining cable sheaths. This material is known for its excellent mechanical properties, including high tensile strength, abrasion resistance, and flexibility.

Chemically, 5GM5 rubber is a synthetic elastomer, which means it combines the elastic properties of rubber with enhanced durability.

One of the standout features of 5GM5 rubber is its resistance to oil and chemicals. In many mining environments, cables are exposed to various substances that could degrade lesser materials.

However, 5GM5 rubber holds up well against these threats, making it an ideal choice for mining cables that need to last in tough conditions.

Chemically, 5GM5 rubber is a blend of various polymers designed to enhance specific properties. It typically includes a mix of ethylene-propylene-diene monomer (EPDM) and nitrile rubber (NBR). EPDM provides excellent resistance to weathering, UV rays, and ozone, which are common in outdoor mining environments.

NBR, on the other hand, offers superior resistance to oil, fuel, and chemicals.

This blend gives 5GM5 rubber its unique balance of flexibility and toughness, making it a versatile option for many mining applications.

Its ability to maintain its properties across a wide range of temperatures is another reason why it’s favored in the industry.

PUR rubber, or polyurethane rubber, is another popular choice for mining cable sheaths. This material is known for its exceptional durability and high mechanical strength.

Unlike 5GM5 rubber, which is a synthetic elastomer, PUR rubber is a thermoplastic material. This means it can be melted and reshaped, giving it a different set of properties compared to traditional rubbers.

One of the most significant advantages of PUR rubber is its extreme abrasion resistance. In mining operations where cables are subject to constant movement and rough handling, PUR rubber can endure wear and tear far better than many other materials.

This makes it particularly useful in environments where cables are frequently dragged or pulled across rocky surfaces.

Chemically, PUR rubber is made from the polymerization of urethane compounds. These polymers are known for their high tensile strength, flexibility, and resistance to various environmental factors.

One of the unique properties of PUR rubber is its ability to be engineered for specific performance characteristics. By altering the chemical composition during manufacturing, PUR rubber can be tailored to meet the exact needs of a particular application.

For example, PUR rubber can be modified to improve its resistance to moisture, UV radiation, or extreme temperatures. This makes it a highly customizable material that can be fine-tuned for use in various mining environments.

Now that we’ve explored the chemical makeup of 5GM5 rubber and PUR rubber, let’s compare their properties to understand where each material shines.

Abrasion Resistance: PUR rubber is the clear winner here. Its high mechanical strength and durability make it ideal for environments where cables are exposed to significant wear and tear.

Oil and Chemical Resistance: 5GM5 rubber takes the lead in this category. Thanks to its NBR content, 5GM5 rubber offers superior resistance to oils, fuels, and chemicals, making it a better choice for applications where chemical exposure is a concern.

Flexibility: Both materials are flexible, but 5GM5 rubber tends to be more elastic, making it easier to handle and install, especially in tight spaces or where the cable needs to bend around obstacles.

Temperature Resistance: 5GM5 rubber offers better performance across a broader range of temperatures. It remains flexible in cold conditions and doesn’t degrade as quickly in high heat, making it more versatile for different mining environments.

Customization: PUR rubber stands out for its ability to be tailored to specific needs. Whether you need enhanced moisture resistance, UV protection, or extreme durability, PUR rubber can be engineered to deliver.

Selecting the right outer sheath material for your mining cables depends on the specific conditions of your operation. If your cables are frequently exposed to oils, chemicals, or harsh weather conditions, 5GM5 rubber might be the best choice. Its superior resistance to these elements ensures that your cables will last longer and perform better in challenging environments.

On the other hand, if your cables are subject to extreme mechanical stress, such as constant dragging or pulling over rough surfaces, PUR rubber could be the better option. Its exceptional abrasion resistance and durability make it ideal for applications where physical damage is a primary concern.

At Feichun Cable, we understand that no two mining operations are the same. That’s why we offer customizable solutions that allow you to choose the right material for your specific needs. Whether you need 5GM5 rubber for its chemical resistance or PUR rubber for its durability, we can help you find the perfect solution.

For operations in high-salinity environments—such as those near the sea—we can incorporate materials like 5GM5 rubber or 3GM3 PUR to protect against corrosion. If your cables need to withstand high tensile stress, we can add a Kevlar braided layer for added strength.

Our goal is to ensure that your mining cables perform reliably, no matter the conditions. By working with us, you can rest assured that you’re getting the most economical and effective cable solution for your operation.

In the demanding world of mining, choosing the right material for your cable sheaths is crucial. 5GM5 rubber and PUR rubber each offer unique benefits, and understanding the chemical differences between them can help you make an informed decision. Whether you prioritize chemical resistance, abrasion resistance, or flexibility, there’s a material that’s right for your needs.

At Feichun Cable, we’re here to help you navigate these choices and find the best solution for your operation. With our expertise and commitment to quality, you can trust that your cables will stand up to whatever challenges your mining environment throws at them.